Process for strengthening assembly hole through cold extrusion of slotted bushing

A technology of slotted bushing and assembling holes, which is applied in the field of hole cold extrusion strengthening precision machining, can solve the problem of large reaming amount, uneven surface residual stress field of hole wall of workpiece with holes, and increase the cost of hole cold extrusion strengthening technology And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

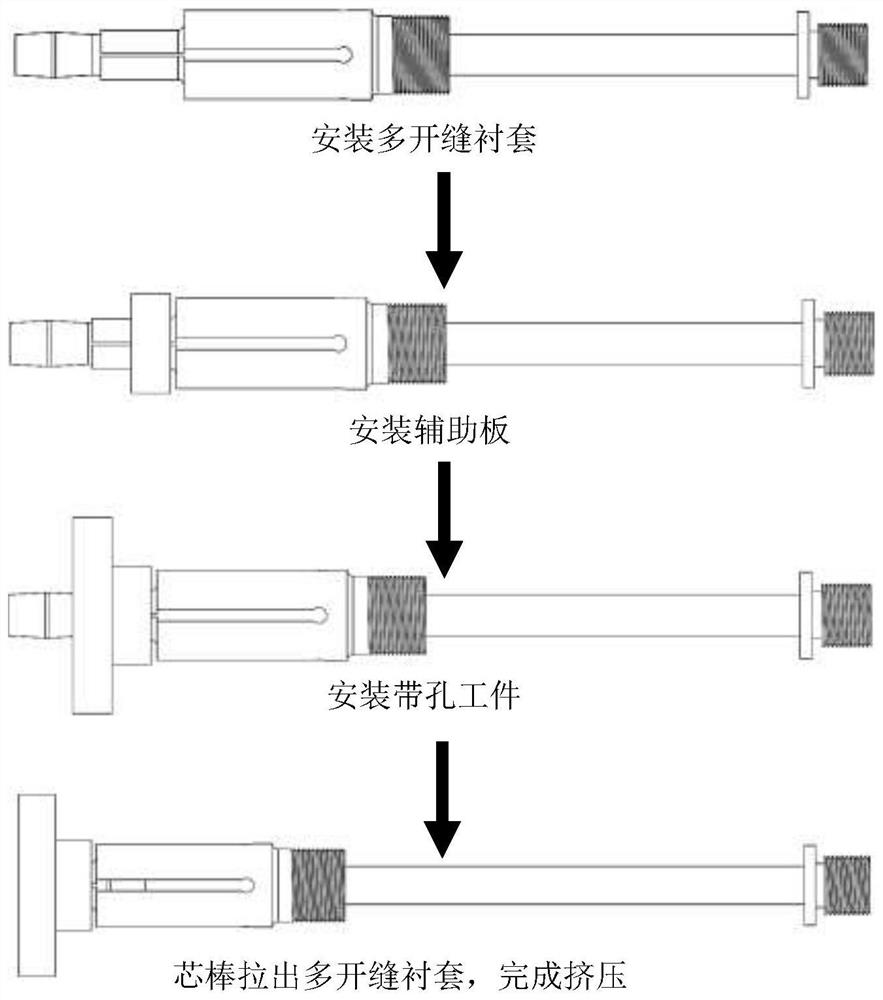

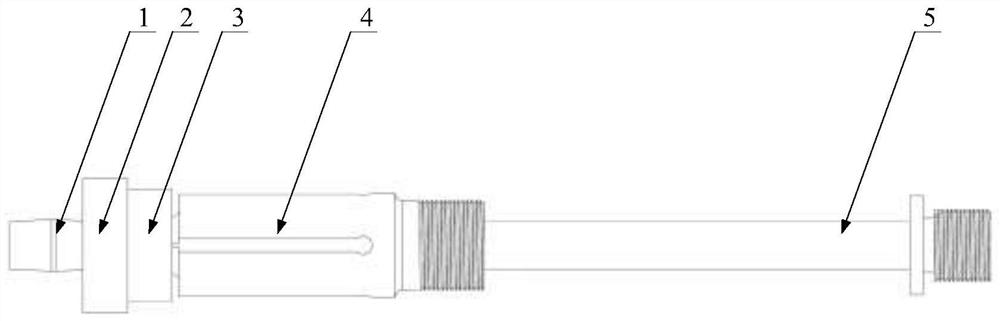

[0029] figure 1 It is a process flow diagram of strengthening the assembly hole by cold extrusion of the slotted bush; figure 2 It is a schematic diagram of a strengthened state of a slotted bush cold extruded strengthened assembly hole of the present invention.

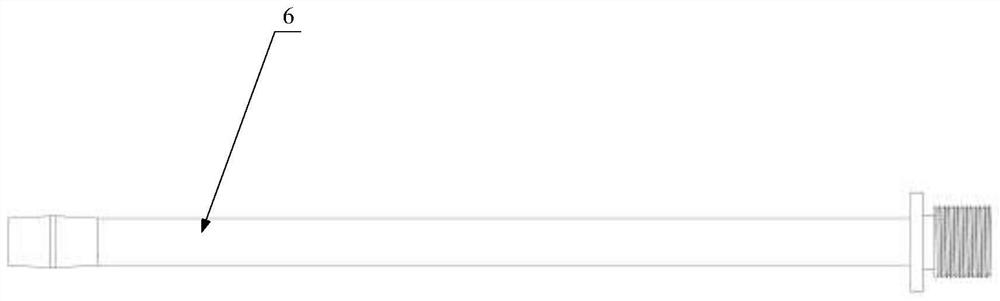

[0030] (1) The slotted bush 4 passes through one end of the extruded mandrel 5 and places it on the guide section 6, and is fixed to the fixture through the thread 8 at the tail. Extrusion mandrel 5 and slit bushing 4 pass through auxiliary plate 3 and workpiece 2 with holes. The auxiliary plate 3 is placed in front of the workpiece 2 with holes, and the holes of the auxiliary plate and the assembly holes of the workpiece with holes have the same diameter and are coaxial.

[0031] (2) When the extruding mandrel 5 is pulled out of the assembly hole of the workpiece 2 with holes at a constant speed, the working ring 1 of the extruding mandrel squeezes the slotted bushing 4, and a plurality of slits are opened on the...

Embodiment 2

[0036] Using the ABAQUS finite element simulation analysis software, the assembly hole of the TC4 titanium alloy plate with a diameter of 60 mm × 60 mm × 10 mm and a central hole diameter of 12.12 mm is used to cool the hole with a extrusion amount of 5% using a single-slit bushing and a 4-slit bushing. Simulation of extrusion strengthening process.

[0037] After the assembly hole of the titanium alloy workpiece with holes is cold extruded and strengthened, the wall of the assembly hole produces residual stress in three directions: radial, tangential, and along the thickness of the plate. The residual stress in the three directions of the hole wall has the greatest influence on the performance of the workpiece with holes is the tangential residual stress. Therefore, in Example 2, only the changes of the distance from the hole wall and the tangential residual stress at different positions of the assembled hole wall of the titanium alloy workpiece with holes after the hole cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com