Method for preparing Ti2AlC phase ceramic coating through cold spraying in-situ formation

An in-situ generation and ceramic coating technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of limited component size, limited coating thickness, low production efficiency, etc., and achieve short heating time, anti-oxidation and anti-corrosion Improved performance and better coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

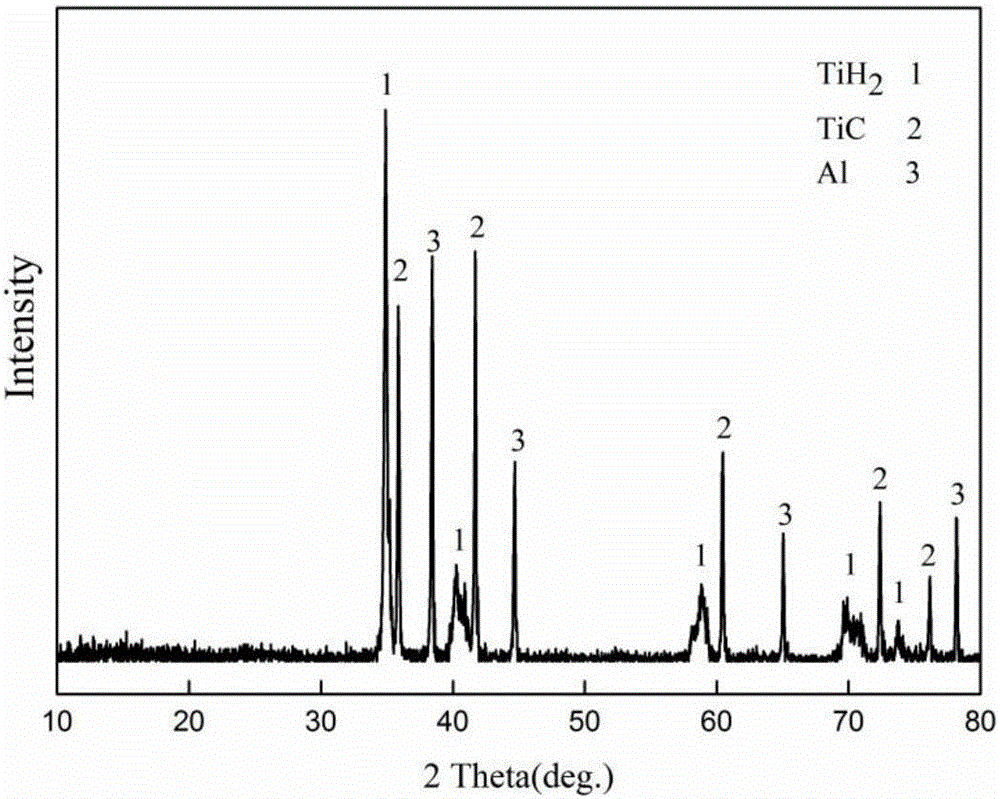

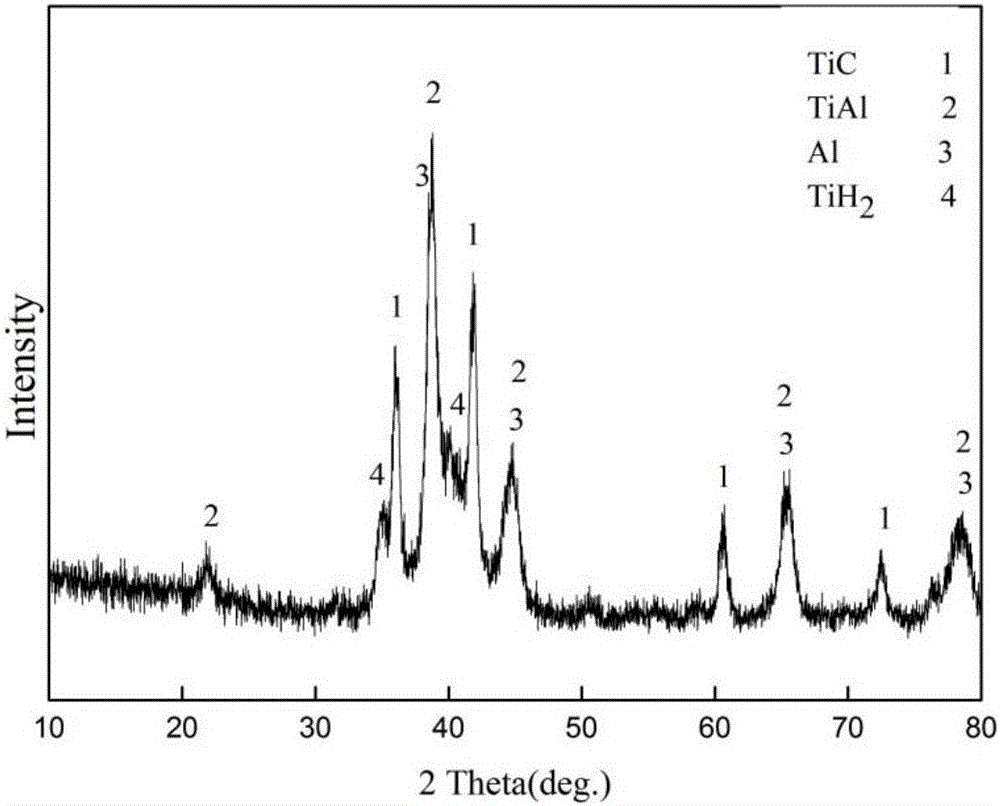

[0032] TiH 2 , Al, TiC powder raw materials are n(TiH 2 ):n(Al):n(TiC)=1:1.1:1 ratio ingredients. Ti H 2 Powder average particle size 800nm, purity 99.9wt%, Al powder average particle size 1 micron, purity 99.9wt%, TiC average particle size 500nm, purity 99.8wt%, raw material weight total 1Kg, stir with a mixer for 30min and mix well.

[0033]Add 15g of polyethylene glycol into 1.5Kg of absolute ethanol, heat and stir in a water bath to form a mixed solution. Add the uniformly mixed powder into the absolute ethanol-polyethylene glycol solution, and put it into a 3L stirring ball mill. In the ball mill mixing stage, the stirring speed is 300r / min, and the time is 30min. In the granulation stage, remove the grinding balls, adjust the stirring speed to 50r / min, and maintain it until the atomization granulation process stops. The slurry is atomized and dried into a spherical composite powder of about 10 microns with an organic solvent-based laboratory spray dryer with an iner...

Embodiment 2

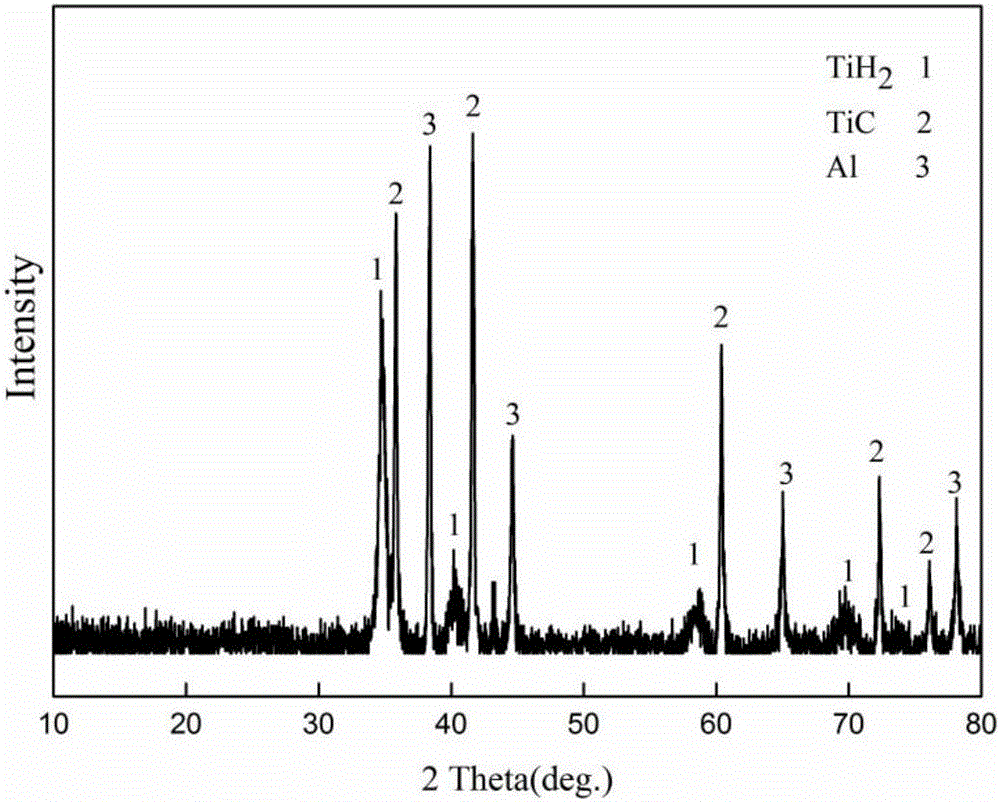

[0036] TiH 2 , Al, TiC powder raw materials are n(TiH 2 ):n(Al):n(TiC)=1:1.1:1 ratio ingredients. TiH 2 Powder average particle size 800nm, purity 99.9wt%, Al powder average particle size 1 micron, purity 99.9wt%, TiC average particle size 500nm, purity 99.8wt%, raw material weight total 1Kg, stir with a mixer for 30min and mix well.

[0037] Add 10g of polyethylene glycol into 1.5Kg of absolute ethanol, heat and stir in a water bath to form a mixed solution. Add the uniformly mixed powder into an anhydrous ethanol-polyethylene glycol solution, and put it into a 3L vibratory ball milling device with a vibration frequency of 50 Hz, an amplitude of 5 mm, and a ball milling time of 30 minutes. Pour out the ball-milled slurry and put it into a 5L beaker while stirring with a stirrer at a stirring speed of 50r / min, and maintain it until the atomization and granulation process stops. Dry the slurry with a centrifugal atomizing dryer with a closed-cycle function. A centrifugal at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com