Method for using balance post rod in drawing process for machining high-tension material asymmetrical component

An asymmetric, high-tension technology, applied in the field of drawing, which can solve the problems of forming limit limitation, high yield limit, and difficulty in reaching the ideal precision, so as to reduce the difficulty and cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

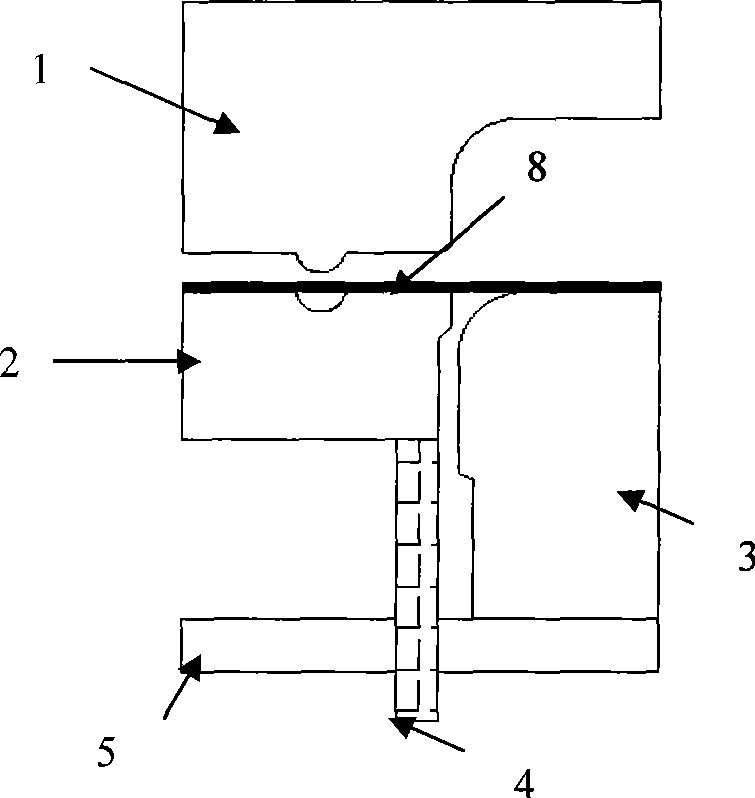

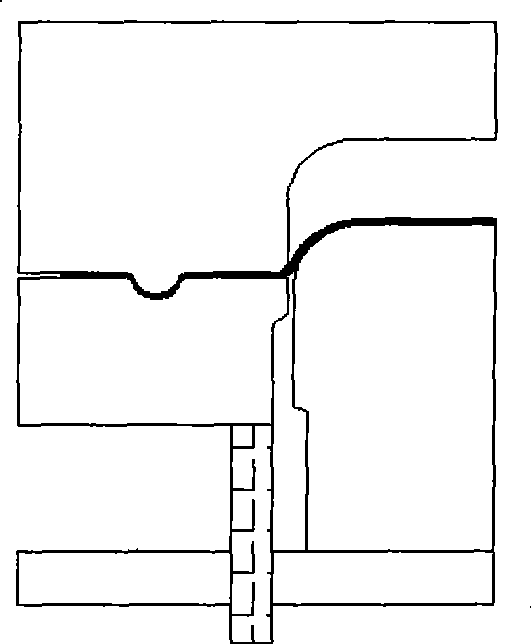

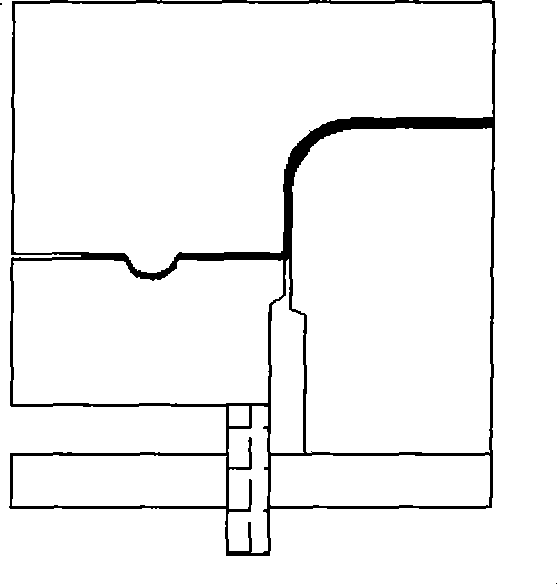

[0018] The molding device used in this method is as Figure 1a Shown: It consists of upper die (1), blank holder (2), punch (3), ejector pin (4), machine table (5) and figure 2 Shown balance ejector rod (6) forms.

[0019] image 3 The inner panel of the front frame of the automobile made of the high-tensile sheet material shown is a left-right asymmetric part, the arrow A is the feeding direction, and the arrow B is the stamping direction. The following combination Figure 1a , Figure 1b , Figure 1c and figure 2 , the implementation process of this method is as follows:

[0020] The first step: while the mold (9) is installed and locked on the machine platform, install the balance ejector pin on the end of the mold that is less stressed during molding.

[0021] Step 2: Lock the upper die (1) and the slider (7) of the machine (5) and move downwards so that the upper die (1) contacts the blank (8) on the blank holder, at this time Adjust the height of the balance ejec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com