Stretching technology for processing high-tension material parts and stretching mould thereof

A drawing die and high tension technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of forming limit limitation, inaccurate forming simulation, poor shapeability of process parts, etc., to reduce difficulty and cycle time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

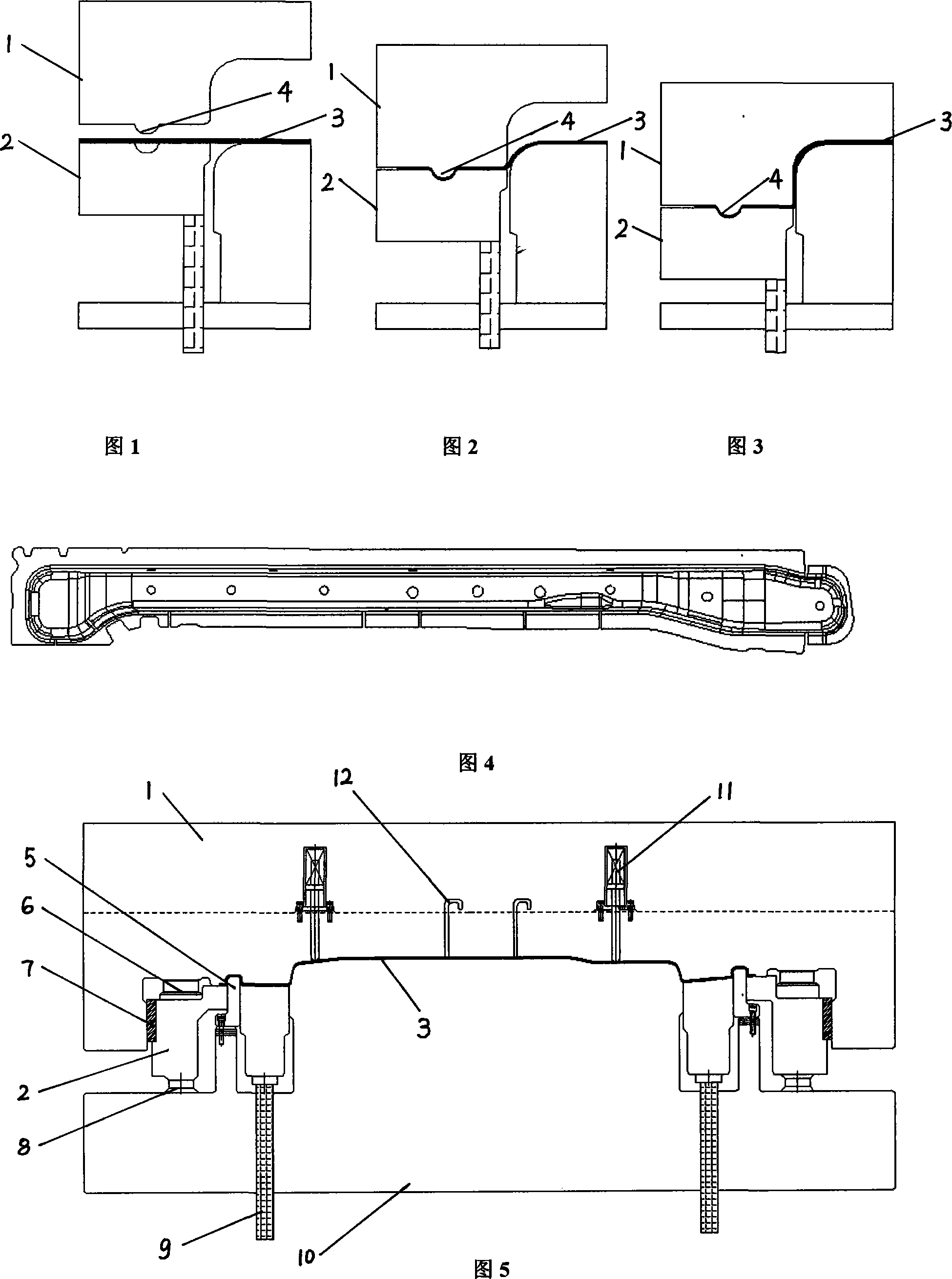

Method used

Image

Examples

Embodiment Construction

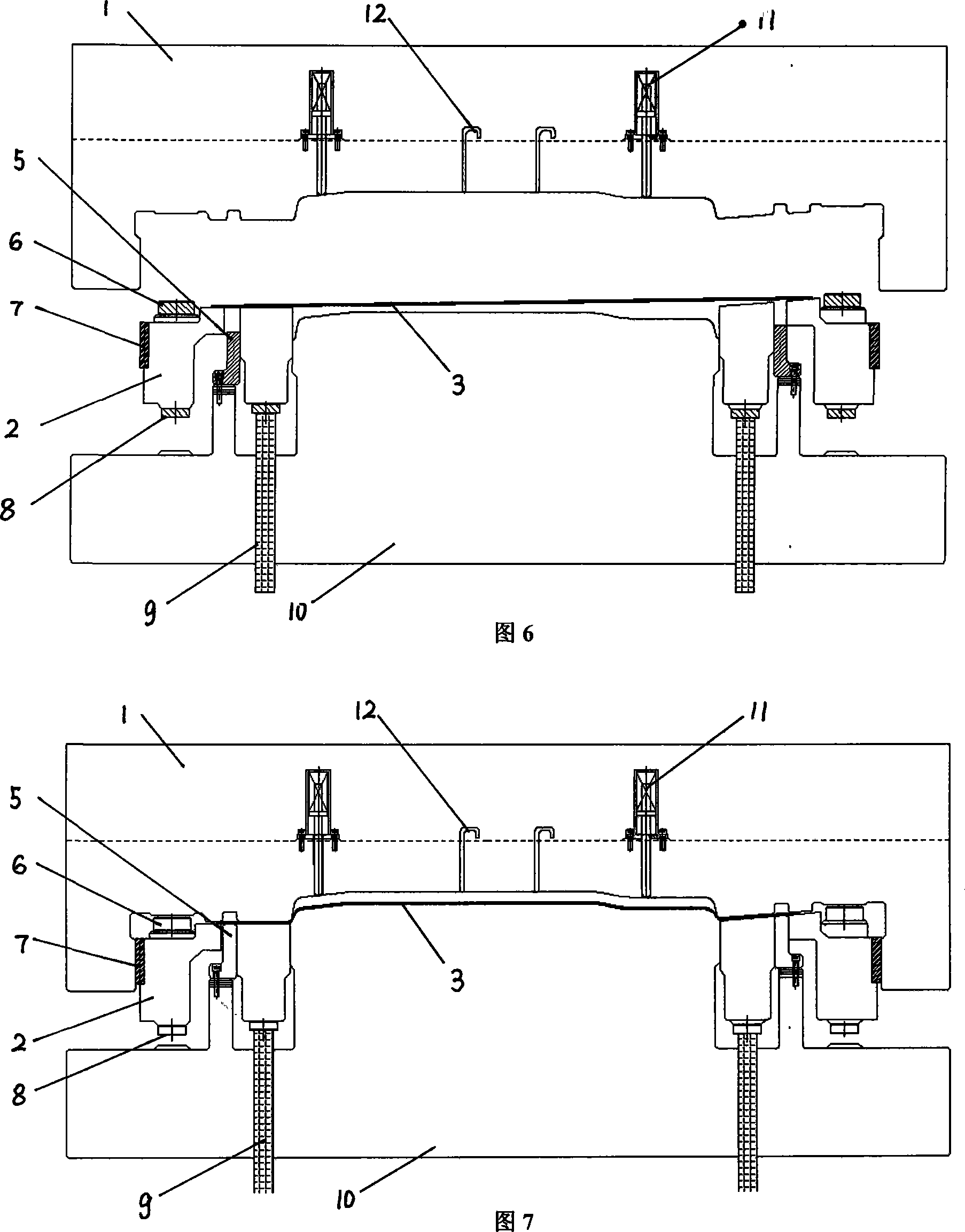

[0024] Figure 4 shows the car side sill reinforcement (cut edge) that needs to be made of high-tensile sheet materials. This part is a safety performance part and plays an important role in the car body. The characteristics of this part are: 1. The total length of the part reaches 2m, and it is easy to twist. 2. The part is closed drawing; 3. The material selected for the part is DP800, which is a typical "double-high" part, and its precision control is difficult.

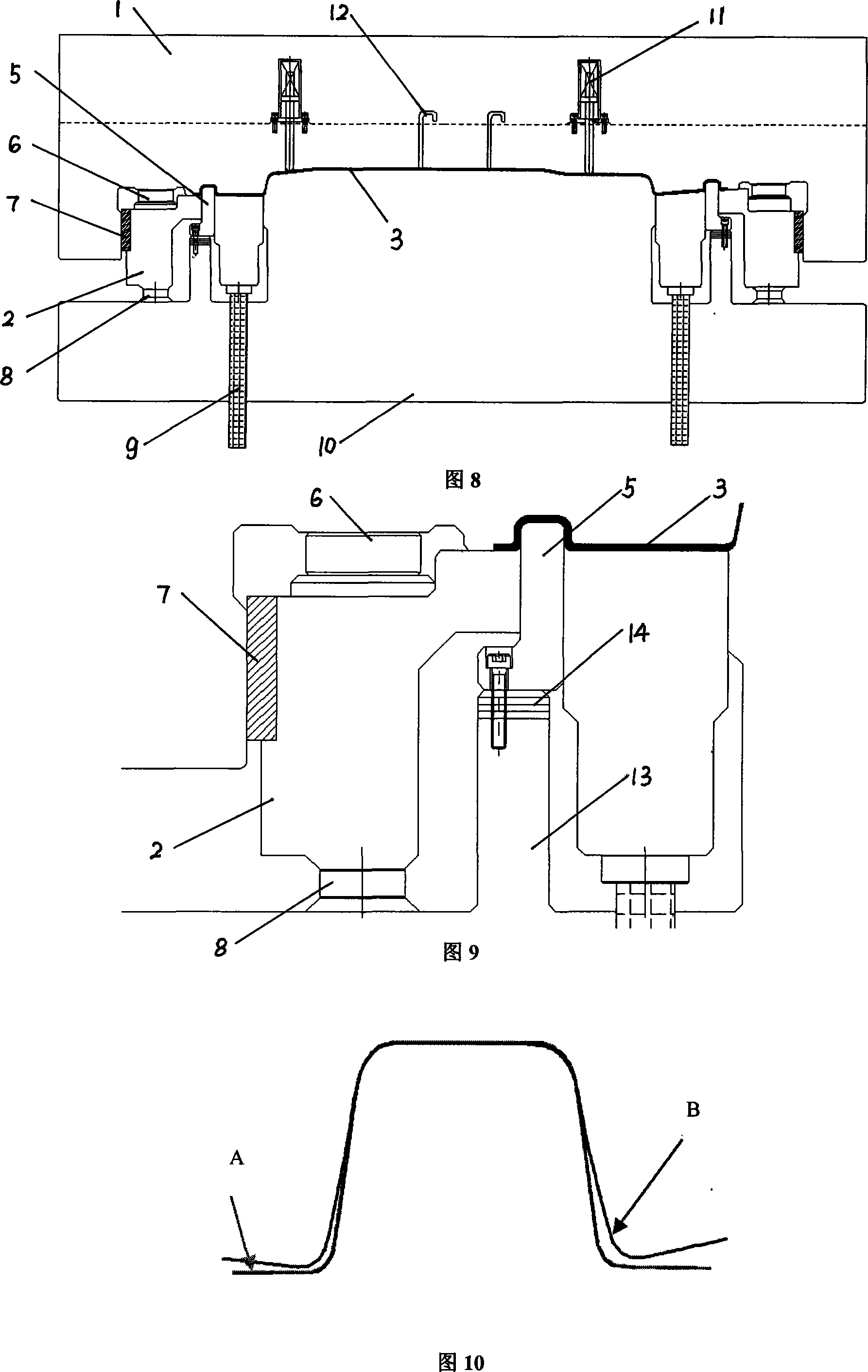

[0025] 5 and 9, the drawing die includes an upper die 1, a lower die 10, a blank holder 2, a process bulging rib 5 and a push rod 9, etc., and an exhaust pipe 12, a push rod 9, etc. are arranged on the upper die 1. Pin 11 is provided with balance weight 6 on the blank holder 2, the side is provided with guide plate 7, and the bottom is provided with components such as pier dead block 8. Wherein the process bulging rib 5 is fixed on both sides of the lower mold 10, and its lower end is connected and fixed with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com