Isotropic rolling method for structural steel rectangular ring

A rectangular ring, isotropic technology, used in metal rolling and other directions, can solve the problems of radial mechanical properties and axial mechanical properties that are quite different, consistent, and cannot guarantee the mechanical properties of rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043] The main chemical element content (percentage by weight) of the alloy is: C content 0.34%-0.42%, Mn content 0.50%-0.80%, Si content 0.17%-0.37%, S content ≤ 0.015%, P content ≤0.025%, Cr content 0.08%~1.10%, Ni content ≤0.40%, Cu content ≤0.25, balance Fe.

[0044] The steps of this method are as follows:

[0045]The structural steel bar blanked according to the specification is heated to the forging temperature, and after upsetting, punching and pre-rolling, the height is H 1 , thickness B 1 , the outer diameter is R 1 rectangular ring blank;

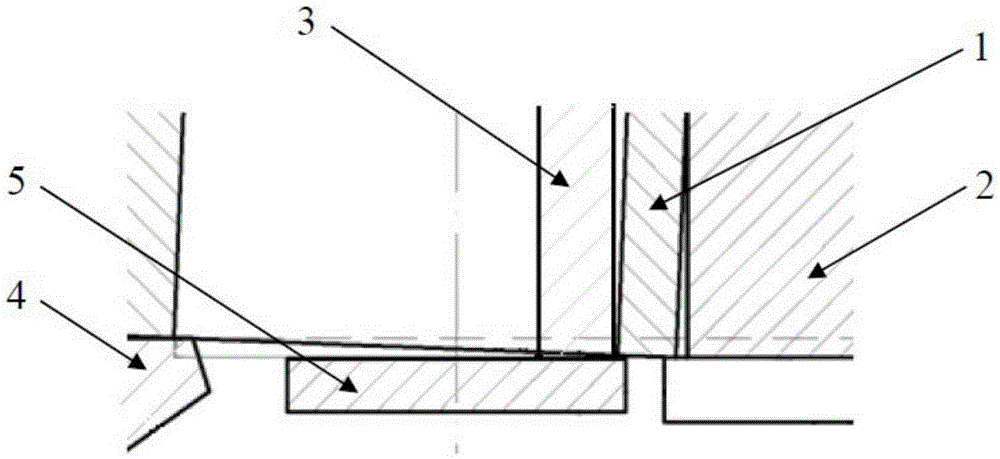

[0046] like figure 1 As shown, the rectangular ring blank 1 is loaded into the ring rolling mill, the core roll 3 passes through the middle of the rectangular ring blank 1, the core roll 3 is driven and the rectangular ring blank 1 approaches the main roll 2, and then the tapered roll 4 is driven Near the other side of the rectangular ring blank 1, the upper and lower tapered rollers 4 clamp the rectangular ring blank 1 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com