Method for performing surface modification on inner wall and outer wall of tube by adopting atmospheric-pressure plasma

A plasma, inner and outer wall technology, applied in the direction of plasma, electrical components, etc., can solve the problems of length limitation, limited jet penetration length, etc., and achieve the effects of low cost, improved surface energy, simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

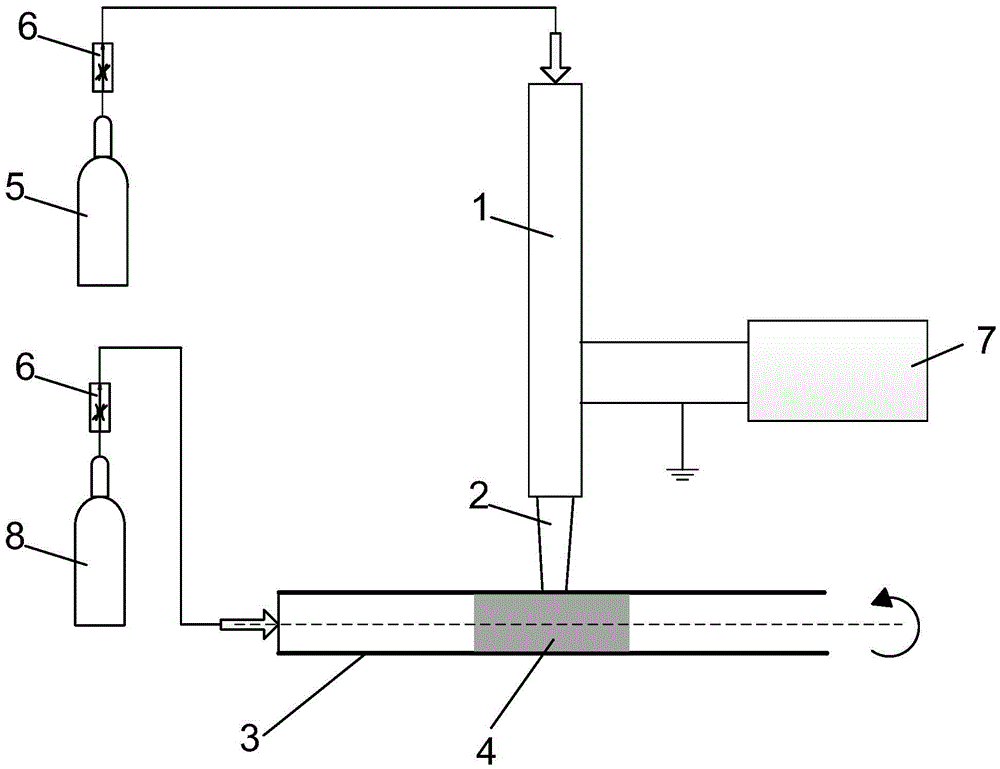

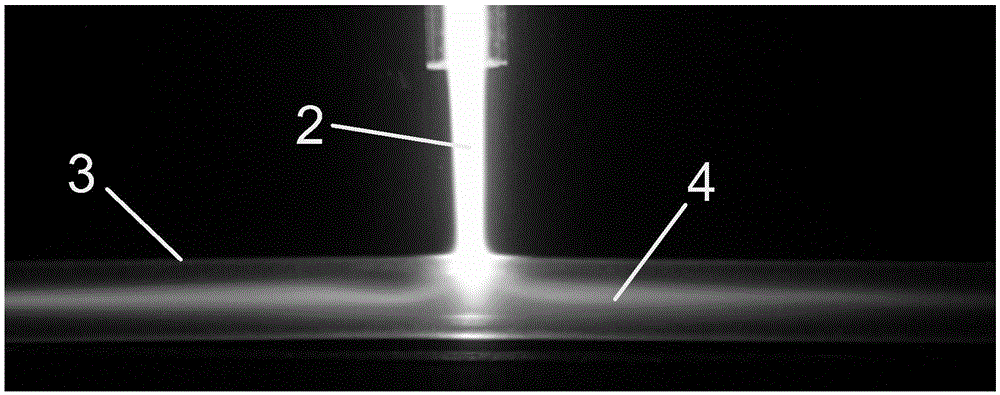

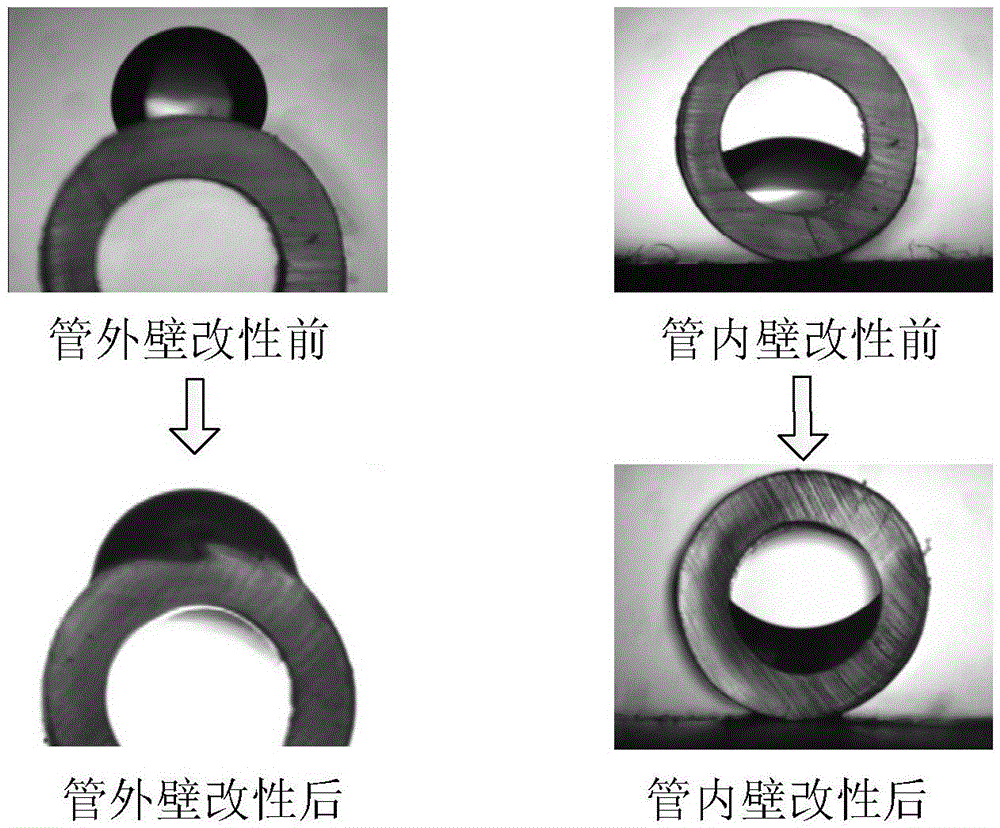

[0021] Such as figure 2 and image 3 Shown is the embodiment provided by the present invention. The selected working gas source 5 is argon, the working gas source 8 is helium, the high-voltage power supply 7 is an AC power supply, the output frequency is 50-120kHz, the output voltage is 0-10kV, the maximum power is 150W, the plasma jet 2 and the tubular material to be processed The vertical distance between 3 is 10mm. figure 2 Shown is the plasma jet 2 generated by the dielectric barrier discharge and the plasma 4 induced in the tubular material 3 to be treated, the modification time is 30 seconds, image 3 Shown are photos of water droplets on the surface of the inner and outer walls of the tube before and after modification, which shows that the wettability of the inner and outer walls of the tube is greatly improved after modification. It can be seen that this method can effectively modify the surface of the inner and outer walls of the tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com