Electric power converter

A power conversion device and package technology, which is applied to circuit thermal devices, output power conversion devices, circuits, etc., can solve the problems of thermal damage to components, low heat-resistant temperature, and elevated temperature, and achieve miniaturization, reduction, and simplification. Support structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0096] -Overall composition-

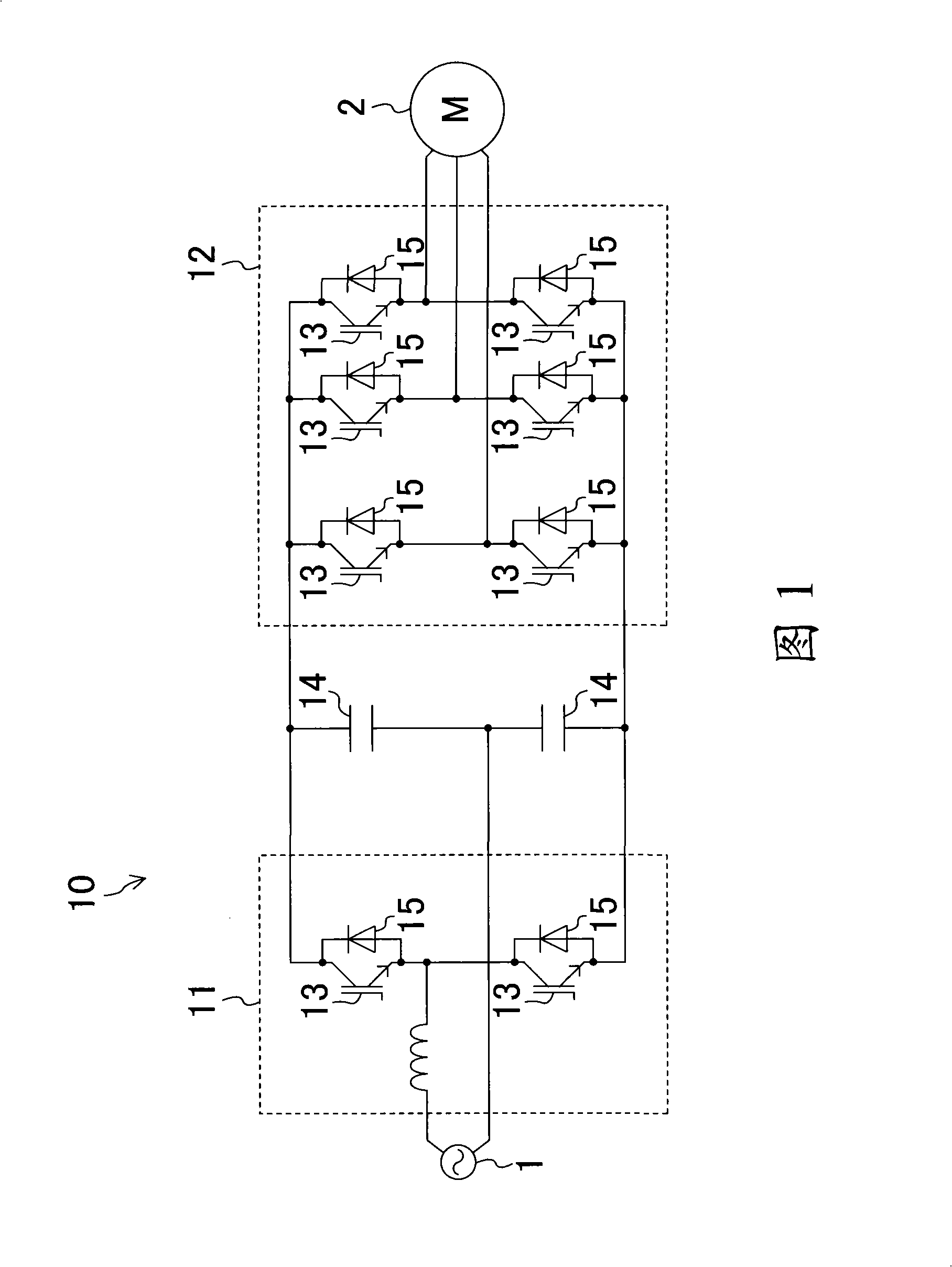

[0097] FIG. 1 shows an example of a circuit of a power conversion device 10 according to Embodiment 1 of the present invention. This power conversion device 10 includes a converter 11 for converting an AC voltage into a DC voltage, and an inverter 12 for converting the DC voltage converted by the converter 11 into a three-phase AC voltage. The converter 11 is connected to To the AC power source 1, the inverter 12 is connected to the motor 2 as a load.

[0098] The above-mentioned converter 11 and the inverter 12 have a plurality of main switching elements 13, 13, ..., and rectification from AC voltage to DC voltage is performed on the above-mentioned converter 11 by switching operations of the main switching elements 13, 13, .... Operation and power conversion operation of converting DC voltage to three-phase AC voltage on the above-mentioned converter 12 .

[0099] In addition, in the power conversion device 10, the two capacitors 14, 14 for s...

Embodiment approach 2

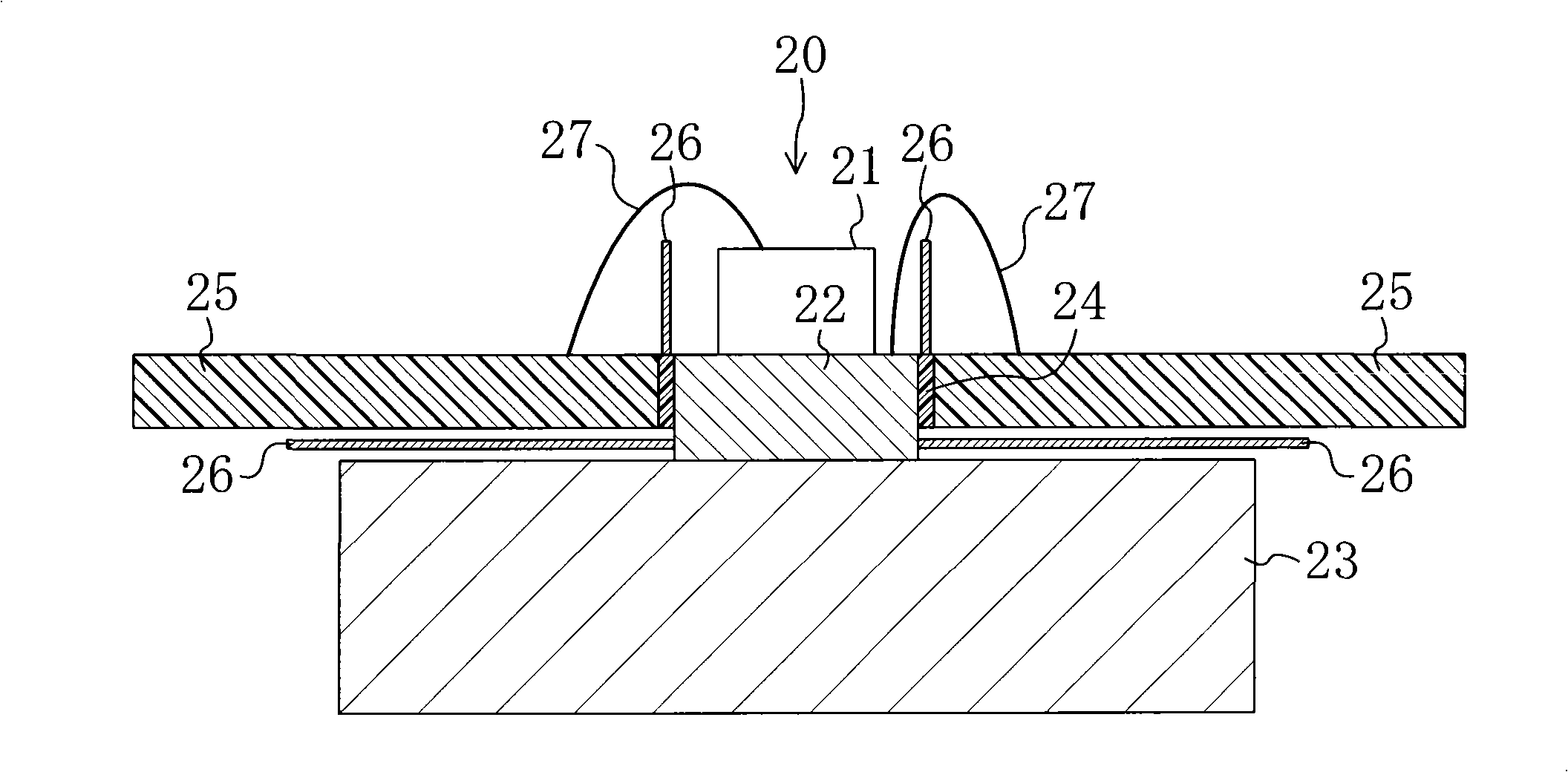

[0121] This second embodiment is different from the above-mentioned first embodiment in that the package 41 in which the chip 21 is sealed is not thermally insulated inside, but heat conduction to the substrate 42 side is suppressed externally.

[0122] In detail, such as Figure 4 As shown, a package 41 encapsulating a chip formed of a wide bandgap semiconductor such as silicon carbide (SiC) is connected to a printed circuit board 43 made of resin, for example, through a plurality of terminals 42, 42, . . . . In more detail, the surface of the above-mentioned printed substrate 43 ( image 3 In the lower surface), a pattern 44 is formed on which the above-mentioned terminals 42, 42, . . . are electrically connected.

[0123] On the other hand, in the package 41, a heat sink 45 is provided on the side opposite to the printed circuit board 43, and the heat sink 45 is configured to dissipate heat from the sealed package 41 of the chip.

[0124] And, the terminals 42, 42, ... of t...

Embodiment approach 3

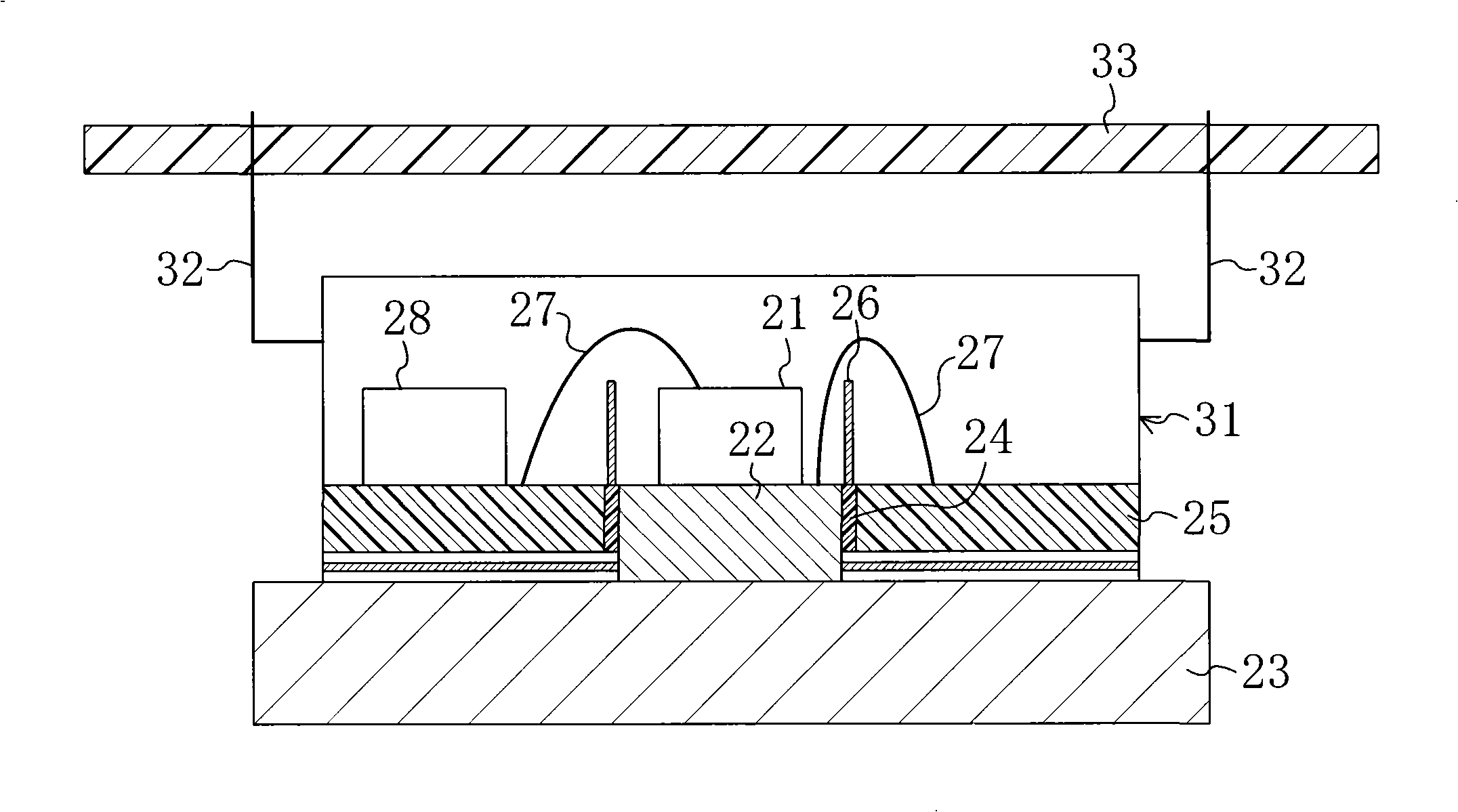

[0136] This Embodiment 3 is different from the above-mentioned Embodiment 2 in that the package body 41 is not directly assembled on the printed circuit board 43 , but is connected to the low heat-resistant Sexual printed substrate 53. Also, the same configurations as those in the above-mentioned second embodiment are denoted by the same reference numerals, and only different parts will be described.

[0137] Specifically, as Figure 5 As shown, a package 41 encapsulating a chip of a wide bandgap semiconductor such as silicon carbide (SiC) is mounted on a highly heat resistant printed circuit board 51 having a heat resistance temperature higher than the temperature at which the wide bandgap semiconductor can operate. Such a highly heat-resistant printed circuit board 51 is, for example, a highly heat-resistant resin or a metal substrate.

[0138] Furthermore, the high heat-resistant printed circuit board 51 assembled with the above-mentioned package 41 is connected to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com