Energy-saving consumption-reducing UV mould press

A technology for molding presses and workbenches, which is used in printing presses, rotary printing presses, general parts of printing machinery, etc., can solve the problems of large machine space occupation, large influence of production product deformation, and large environmental impact of temperature and ozone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

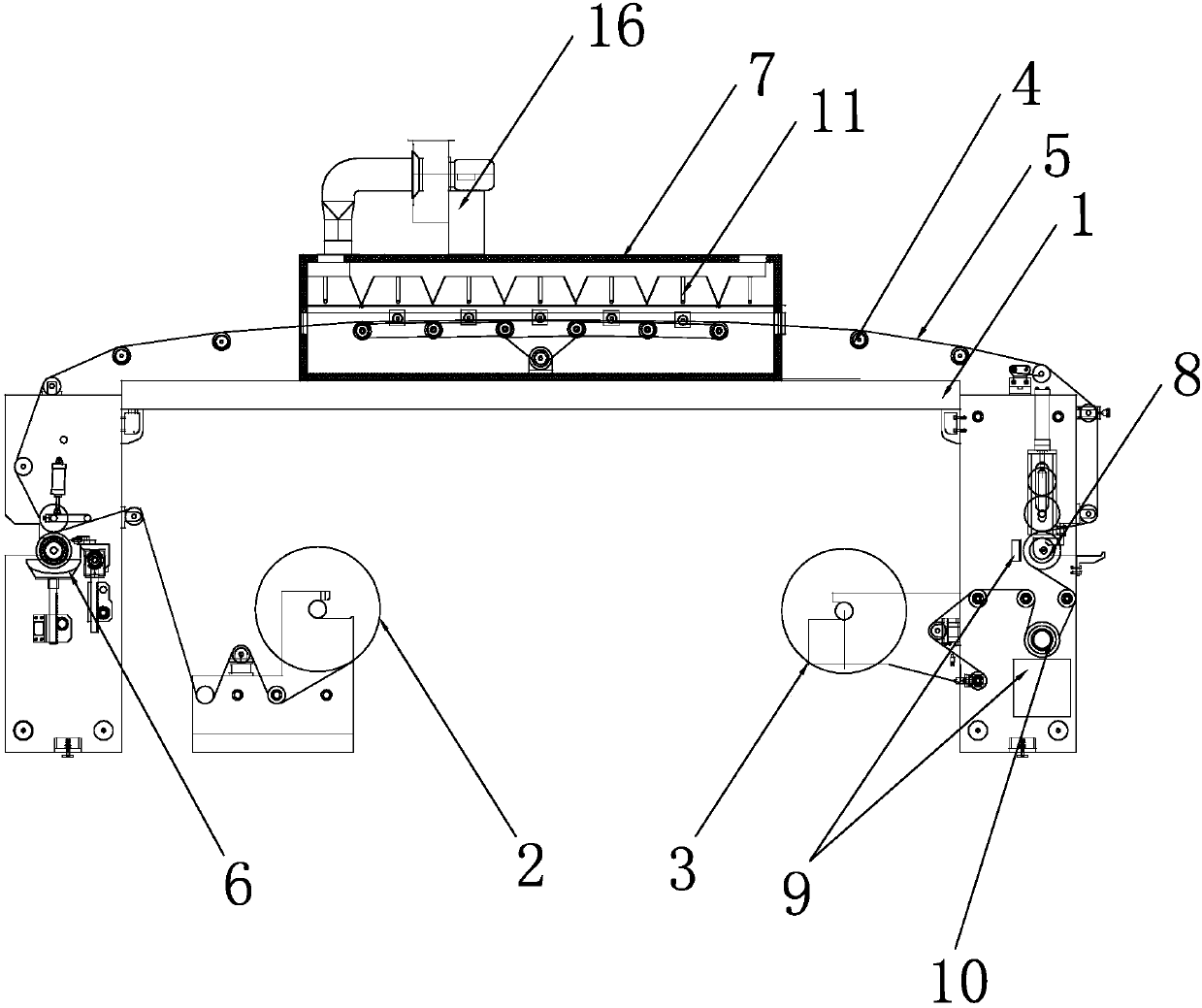

[0020] see figure 1 , an energy-saving and consumption-reducing UV molding machine of the present invention includes a worktable 1 and an unwinding unit 2 and a winding unit 3 arranged on the working table 1, and the unwinding unit 2 and the winding unit 3 are connected by a transmission Roller 4 conveys original film 5, and described workbench 1 is provided with coating tank 6, drying channel 7, nickel plate plate roll 8, UV LED lamp 9 and cooling roll 10 successively along the conveying direction of original film 5, and described nickel plate Version roller 8, cooling roller 10 and driving roller 4 are synchronously driven.

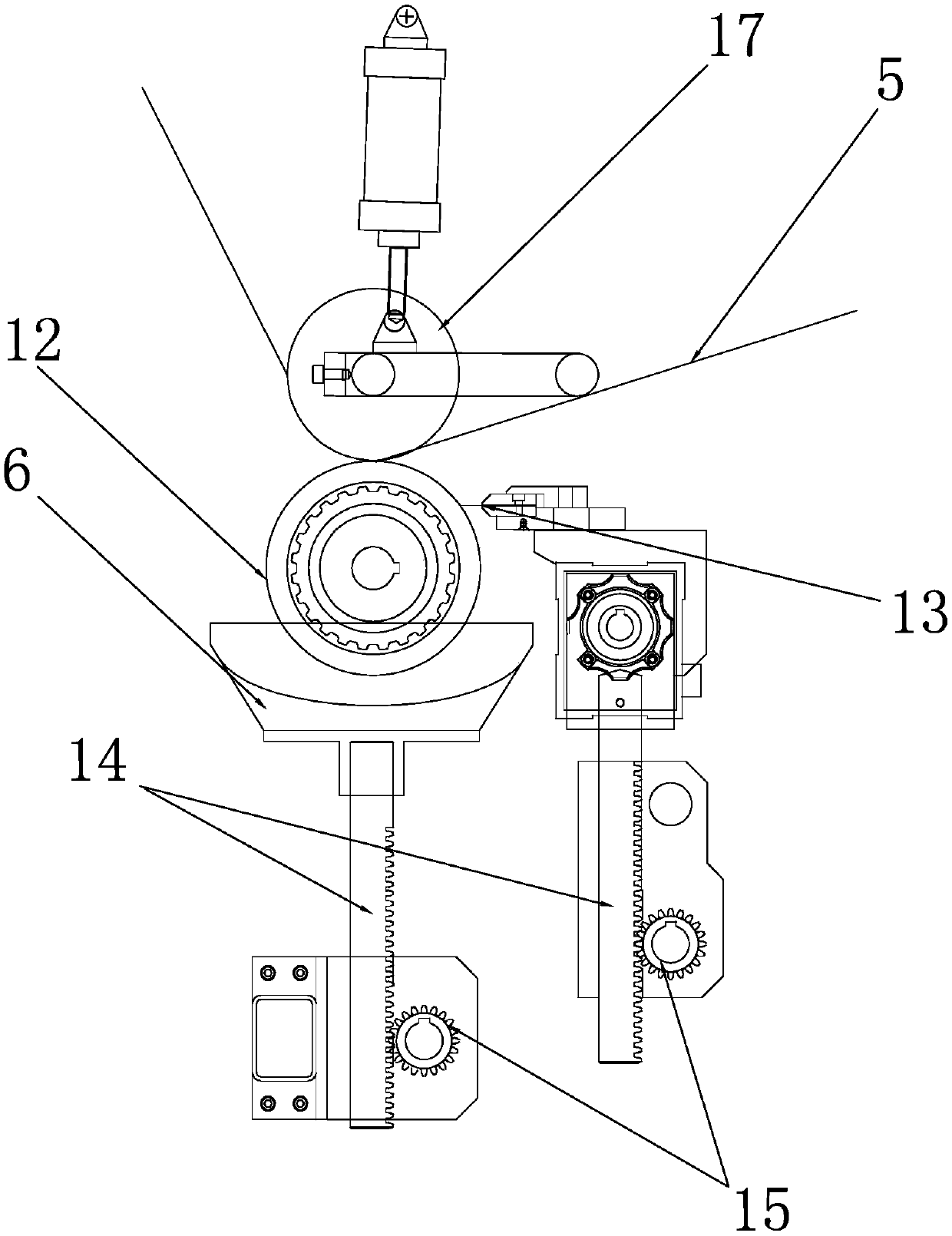

[0021] see further figure 2 , the coating tank 6 is filled with UV paint for coating the original film 5, and the workbench 1 is located above the coating tank 6 and is provided with an anilox roller 12 synchronously driven with the drive roller 4, and the anilox roller The lower end of 12 extends into the UV coating in the coating tank 6, and the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com