Single-lens multi-angle high-magnification photonic chip coupling and packaging device

A photonic chip and packaging device technology, applied in the fields of optoelectronics and integrated optics, can solve the problems of large size, increased cost, unfavorable coupling alignment, etc., and achieves high linear displacement accuracy and angular displacement accuracy, and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

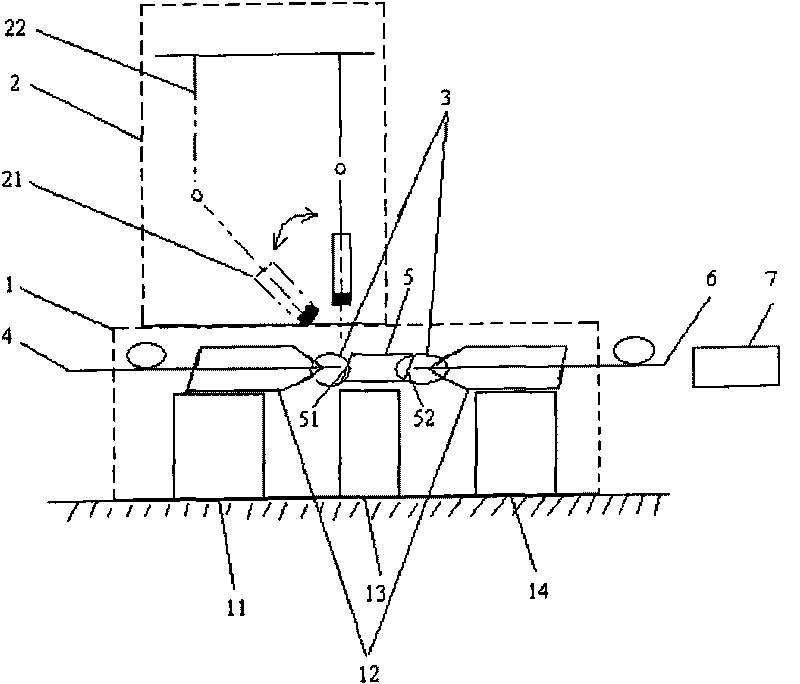

[0046] figure 1 It is a structural representation of the present invention. The coupling adjustment device 1 is composed of a six-dimensional fine-tuning frame 11 , a V-shaped groove 12 , a chip platform 13 and a three-dimensional fine-tuning frame 14 . The machine vision device 2 is composed of a lens camera assembly 21 and a multi-angle fixed swivel device 22 . The optical fiber-chip curing device 3 is an ultraviolet glue curing device using a UV-LED light source. Its specific implementation is as follows:

[0047] ① Fix the chip 5 on the chip platform 13 . Under the observation and guidance of the machine vision device 2, use the three-dimensional fine-tuning frame 14 to manually roughly adjust the output fiber 6 located on the V-shaped groove 12, align with the output end 52 of the chip 5, and lock the three-dimensional fine-tuning frame 14; adjust the lens by fixing the rotary device 22 The camera assembly 21 observes the incident end 51 of the chip 5 , uses the six-d...

Embodiment 2

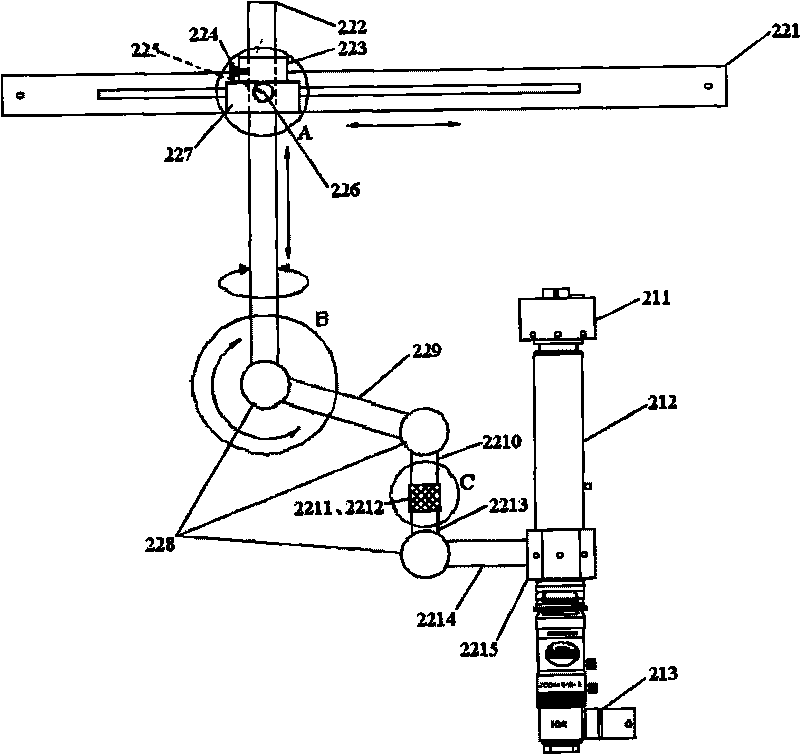

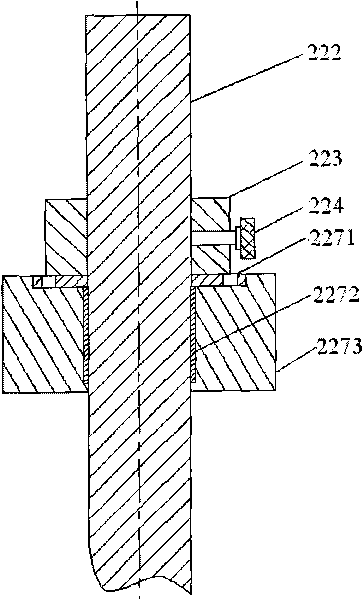

[0051] figure 2 is in the present invention figure 1 The assembly schematic diagram of the core part machine vision device 2 shown. The lens camera assembly 21 is composed of a lens 211 , a camera 212 , and a point light source 213 . The multi-angle fixed swing device 22 consists of a crossbeam 221, a main rod 222, a sliding sleeve 223, a bolt 224, a horizontal fastening bolt 225, a vertical fastening bolt 226, a connecting sliding sleeve 227, a swing adjustment handwheel 228, a first connecting rod 229, The upper connecting rod 2210, the joint 2211, the connecting sleeve 2212, the lower connecting rod 2213, the second connecting rod 2214, and the lens clamp 2215 are composed. Connecting sliding sleeve 227 is made of rod sleeve bottom ring 2271, bushing 2272, main rod sleeve 2273.

[0052] Its specific implementation is as follows:

[0053] ① The vertical adjustment assembly is composed of a main rod 222, a sliding sleeve 223, a bolt 224 and a vertical fastening bolt 226....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com