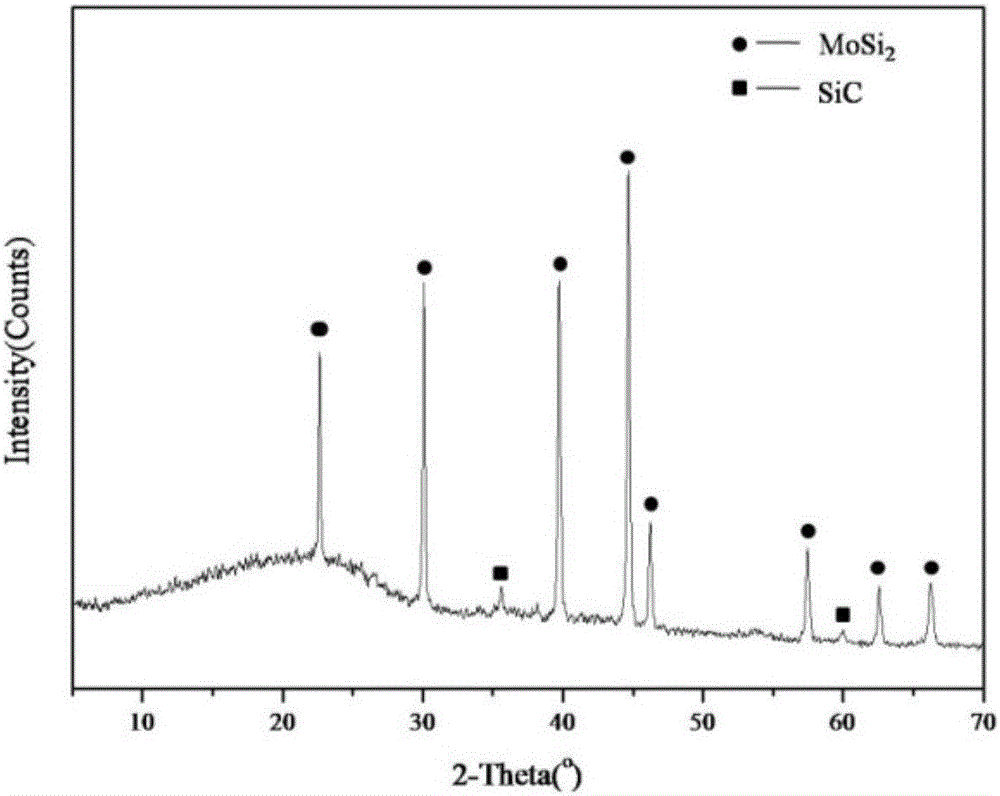

Preparation method for lamellar C/C-SiC-MoSi2 ceramic matrix composite

A technology of c-sic-mosi2 and composite materials, which is applied in the field of preparation of thin-sheet C/C-SiC-MoSi2 ceramic matrix composite materials, can solve the problems of decreased strength of fiber reinforcement, low mechanical properties of composite materials, and stability of composite materials Low and other problems, to achieve the effect of increased density, good friction and wear performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Disperse silicon carbide powder and molybdenum disilicide powder in isopropanol respectively to obtain mixture A and mixture B. The silicon carbide powder concentration in mixture A is 15g / L, and the molybdenum disilicide concentration in mixture B is 35g / L. L. Mixture A and Mixture B were ultrasonically shaken for 60min (ultrasonic power was 800W), and then magnetically stirred for 3h to obtain suspension A and suspension B;

[0039] 2) In suspension A, suspension B, add iodine elemental substance respectively to obtain mixture A 1 , mixture B 1 , mixture A 1 , mixture B 1 The concentration of the iodine element in the medium is 5.0g / L, and the mixture A is 1 , mixture B 1 While heating to 80°C, magnetic stirring was performed for 3h to obtain suspension A. 2 , suspension B 2 ;

[0040] 3) Set the density to 0.2g / cm 3 The carbon fiber three-dimensional fabric (manufacturer: Jiangsu Tianniao High-tech Co., Ltd.) is cut into discs with a diameter of 3cm and a...

Embodiment 2

[0049] 1) Disperse silicon carbide powder and molybdenum disilicide powder in isopropanol to obtain mixtures A and B. The concentration of silicon carbide powder in mixture A is 20 g / L, and the concentration of molybdenum disilicide in mixture B is 30 g / L. The mixtures A and B were ultrasonically shaken (ultrasonic power was 800W) for 60min, and then magnetically stirred for 3h to obtain suspensions A and B;

[0050] 2) in suspension A, B, add iodine element respectively to obtain mixture A 1 , B 1 , mixture A 1 , B 1 The concentration of iodine element in the medium is 5.5g / L, and the mixture A is 1 , B 1 While heating to 80°C, magnetic stirring was performed for 3h to obtain suspension A. 2 , B 2 ;

[0051] 3) Set the density to 0.3g / cm 3 The carbon fiber three-dimensional fabric (manufacturer: Jiangsu Tianniao High-tech Co., Ltd.) is cut into discs with a diameter of 4cm and a thickness of 1cm;

[0052] 4) Place the disc in a 1 mol / L glucose solution for homogeneou...

Embodiment 3

[0059] 1) Dispersing silicon carbide powder and molybdenum disilicide powder in isopropanol to obtain mixtures A and B, the concentration of silicon carbide powder in mixture A is 20g / L, and the concentration of molybdenum disilicide in mixture B is 35g / L. The mixtures A and B were ultrasonically shaken for 60 min, and then magnetically stirred for 4 h to obtain suspensions A and B;

[0060] 2) in suspension A, B, add iodine element respectively to obtain mixture A 1 , B 1 , mixture A 1 , B 1 The concentration of the iodine element in the medium is 6g / L, and the mixture A is 1 , B 1 While heating to 80°C, magnetic stirring was performed for 4h to obtain suspension A. 2 , B 2 ;

[0061] 3) Set the density to 0.4g / cm 3 The carbon fiber three-dimensional fabric is cut into discs with a diameter of 5cm and a thickness of 1cm;

[0062] 4) Place the disc in a 0.8mol / L glucose solution for 180°C homogeneous hydrothermal treatment for 7h, deposit a carbon layer on the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com