Flexible transparent film having novel electrode structure and preparation method flexible transparent film

A technology of electrode structure and transparent film, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problem of poor high temperature resistance of organic flexible substrates, reduce the light transmittance of transparent conductive films, and it is not easy to obtain a flat surface, etc. problem, to achieve the effects of simple control, simplified preparation process, and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Place the PPA film body on a two-dimensional movable platform, so that the film body and the platform are closely attached. There are regularly arranged air pumping holes distributed on the platform, and when the film body is placed on the platform, the air pumping holes pump air so that the film body is closely attached to the platform.

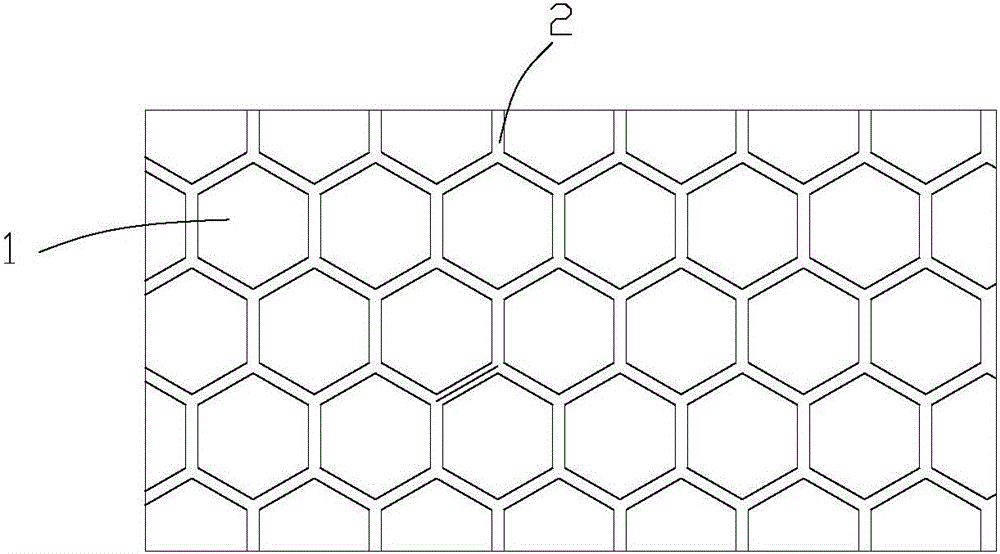

[0028] B. Using an ultraviolet fiber laser to control the relative movement of the focus point of the laser beam and the platform according to the shape of the required electrode, etch a groove on the film body. The wavelength range of the ultraviolet fiber laser used is 200-500nm, the pulse width is 1-20ns, the pulse frequency is 1-1000Hz, and the relative moving speed between the focus point of the laser beam and the platform is 5mm / min-5000mm / min. The trench obtained after this step has a line width of 1 μm and a depth of 1 μm.

[0029] C. The graphene ink is filled into the groove by scraping, followed by sintering and curing,...

Embodiment 2

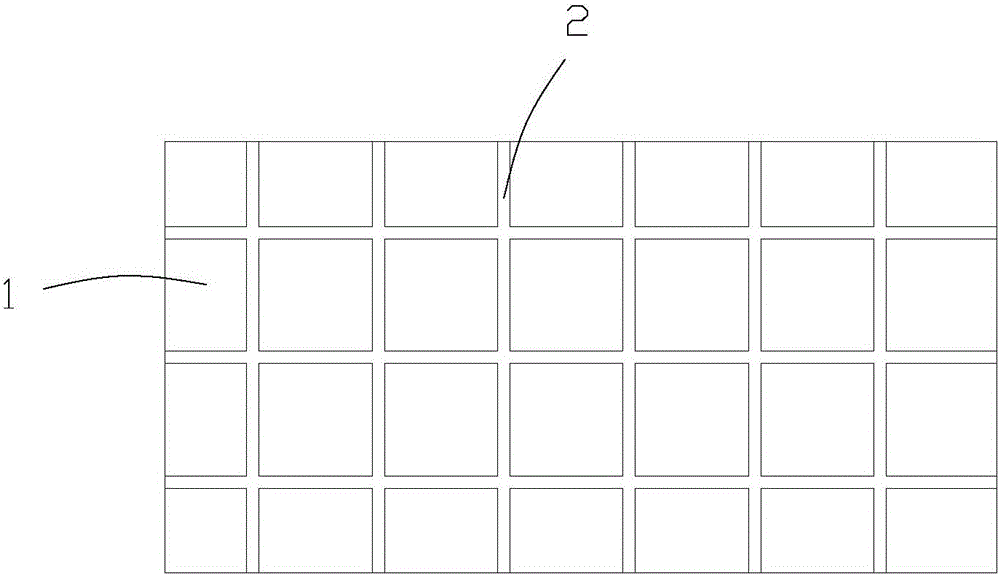

[0031] A. Place the PET film body on a two-dimensional movable platform, so that the film body and the platform are closely attached. There are regularly arranged air pumping holes distributed on the platform, and when the film body is placed on the platform, the air pumping holes pump air so that the film body is closely attached to the platform.

[0032] B. Using an ultraviolet fiber laser to control the relative movement of the focus point of the laser beam and the platform according to the shape of the required electrode, etch a groove on the film body. The wavelength range of the ultraviolet fiber laser used is 200-500nm, the pulse width is 1-20ns, the pulse frequency is 1-1000Hz, and the relative moving speed between the focus point of the laser beam and the platform is 5mm / min-5000mm / min. The trench obtained after this step has a line width of 20 μm and a depth of 20 μm.

[0033] C. Fill the conductive silver ink into the groove by aerosol printing, and then sinter and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Pulse frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com