Anti-wrinkle soft uniform fabric and production process thereof

A technology for fabrics and tooling, applied in the field of wrinkle-resistant and soft tooling fabrics and their production processes, can solve the problems of poor wearing comfort, poor wrinkle resistance and shape retention, and achieve good cooling effect and improve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

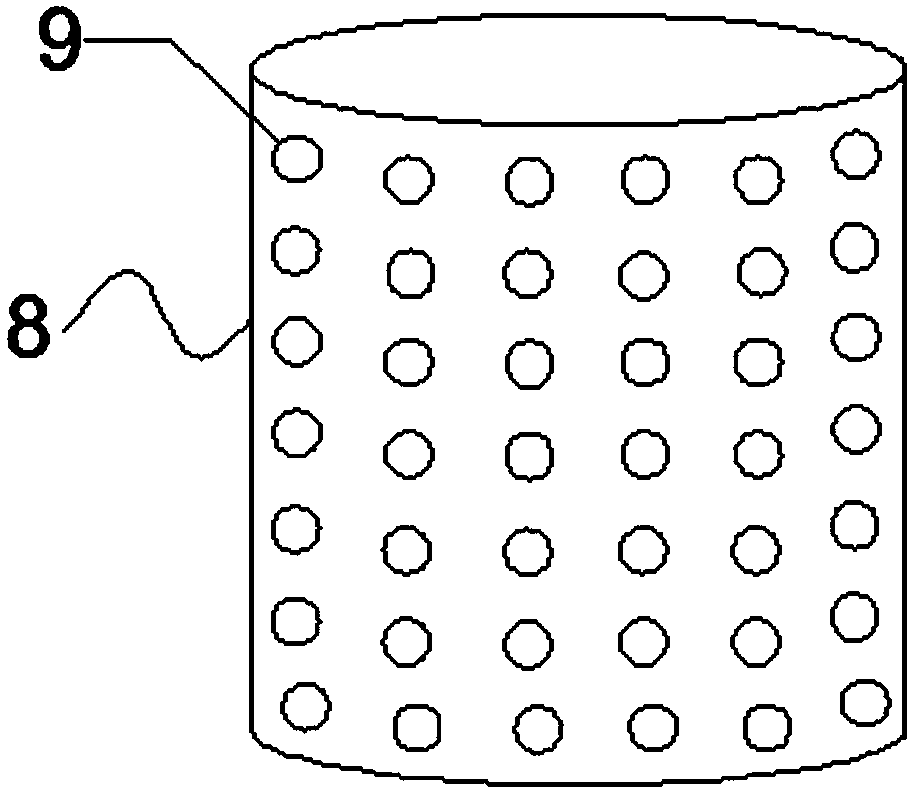

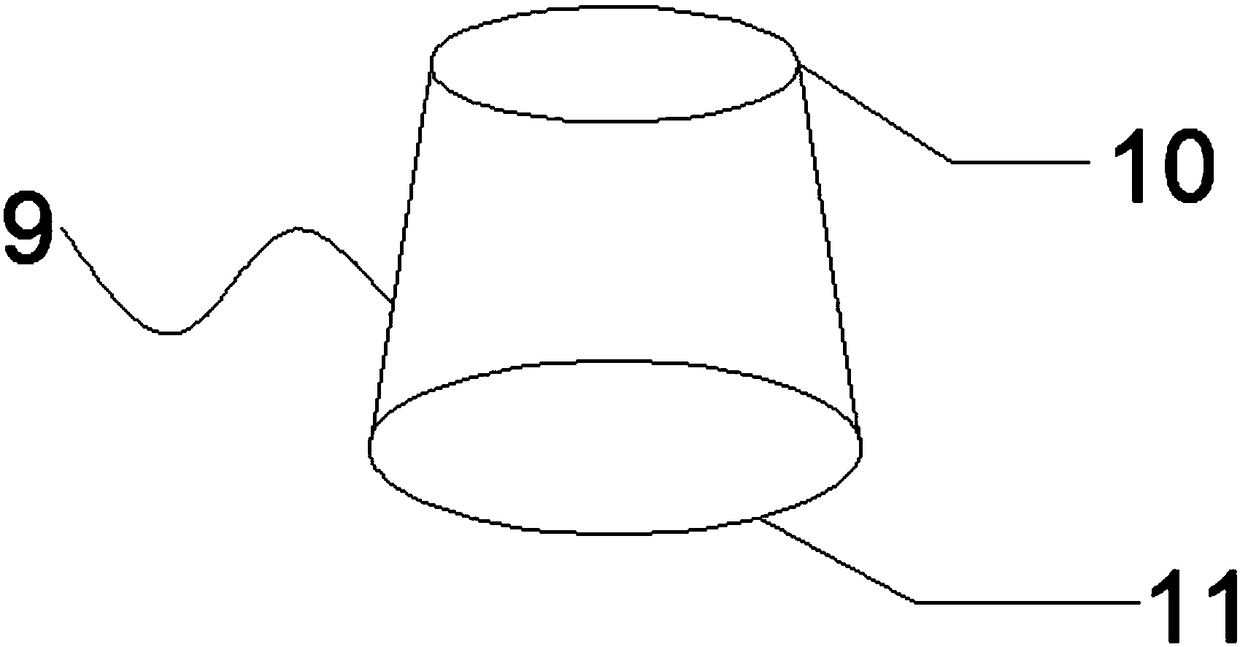

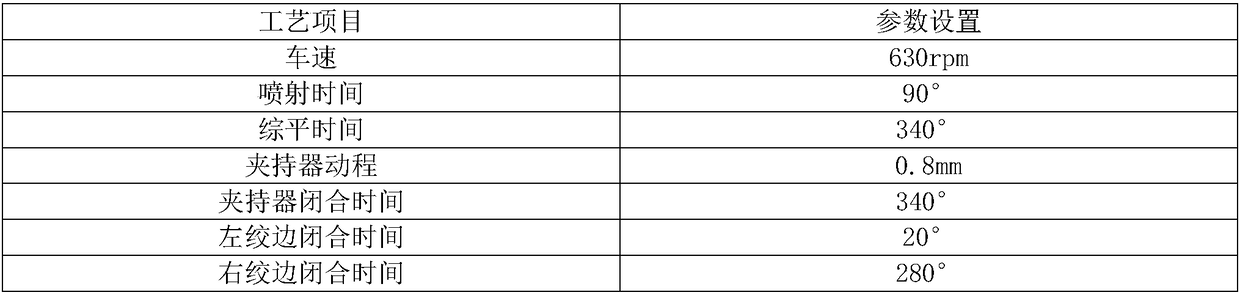

Image

Examples

Embodiment 1

[0052] The present embodiment provides a kind of anti-wrinkle soft tooling fabric, and its production process is as follows:

[0053] (1) Preparation of polyester chips: First, use high-energy ball milling to grind titanium dioxide and zinc oxide into fine powders, and screen out fine powders with a particle size of 10-50 microns, and then use a nano-mill to grind them into fine powders. The zinc oxide and titanium dioxide selected above are mixed evenly at a mass ratio of 1:10, and then ground into ultrafine particles with a particle size less than 400nm to obtain the zinc oxide and titanium dioxide mixture; 0.07% of glycerin, 15% of the zinc oxide and titanium dioxide mixture, Epoxy benzophenone 1.2%, silicon dioxide, barium sulfate 9%, the balance is polyester resin as raw material; under the condition of temperature 280 ℃, put polyester resin, silicon dioxide, barium sulfate into low-speed stirring Stir in the container for 15 minutes to form a molten state; then add nano-...

Embodiment 2

[0058] The present embodiment provides a kind of anti-wrinkle soft tooling fabric, and its production process is as follows:

[0059] (1) Preparation of polyester chips: use high-energy ball milling to grind titanium dioxide and zinc oxide into fine powders respectively, and screen out fine powders with a particle size between 10-50 microns, and then use a nano-mill to grind the above-mentioned The zinc oxide and titanium dioxide that have been screened out are mixed evenly at a mass ratio of 1:6, and then ground into ultrafine particles with a particle size less than or equal to 400nm to obtain the zinc oxide and titanium dioxide mixture; the raw materials are 0.08% glycerin, zinc oxide and titanium dioxide 6% mixture, 0.8% epoxy benzophenone, 8% silicon dioxide, barium sulfate and / or iron oxide, and the balance is polyester resin; at a temperature of 300°C, mix polyester resin and silicon dioxide , barium sulfate and / or iron oxide in a low-speed stirrer and stirred for 10 minu...

Embodiment 3

[0069] The present embodiment provides a kind of anti-wrinkle soft tooling fabric, and its production process is as follows:

[0070] (1) Preparation of polyester chips: use high-energy ball milling to grind titanium dioxide and zinc oxide into fine powders respectively, and screen out fine powders with a particle size between 10-50 microns, and then use a nano-mill to grind the above-mentioned The zinc oxide and titanium dioxide that have been screened out are mixed evenly at a mass ratio of 1:8, and then ground into ultrafine particles with a particle size less than or equal to 400nm to obtain the zinc oxide and titanium dioxide mixture; the raw materials are 0.075% glycerin, zinc oxide and titanium dioxide mixture 10%, epoxy-based benzophenone 1.0%, iron oxide 8.5%, and the balance being polyester resin; at a temperature of 290°C, put polyester resin and iron oxide in a low-speed stirrer and stir for 13 minutes to form a molten state; then add nano-zinc oxide, titanium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com