Room-temperature high-plasticity magnesium alloy and preparation method thereof

A technology for magnesium alloy and casting magnesium alloy, which is applied in the field of Mg-Bi-Y-Mn high plasticity flame-retardant magnesium alloy and its preparation, can solve the problems of low room temperature plasticity of magnesium alloy, etc. Incorrect movement, the effect of promoting dynamic recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

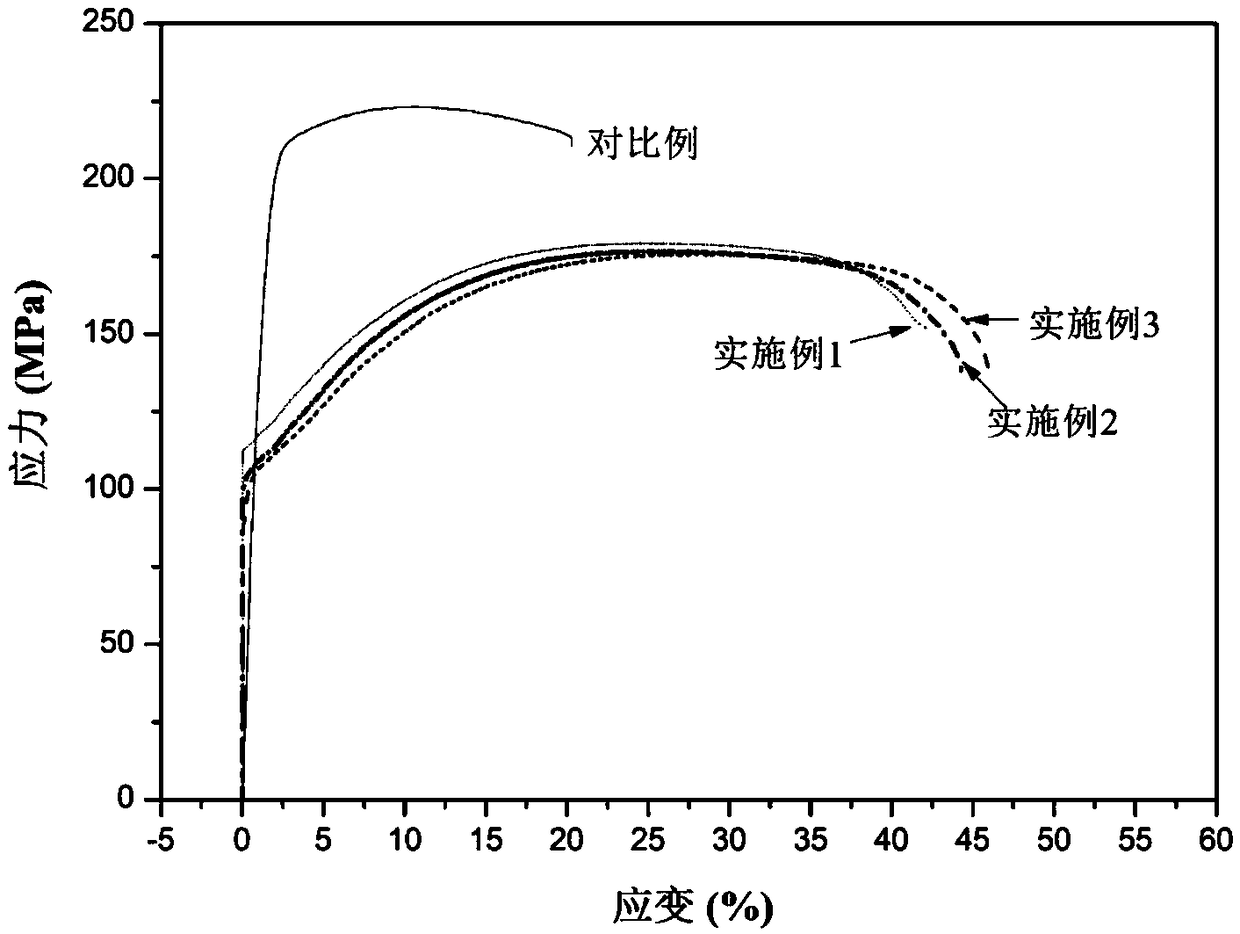

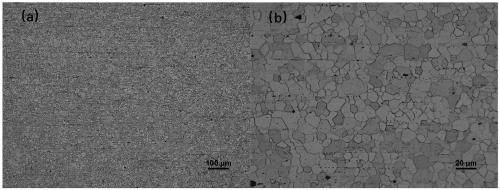

[0046] (1) Design and select Mg-5Bi-2.8Y-0.06Mn (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps:

[0047] 1) Ingredients: Use pure Mg ingot, pure Bi block, Mg-30Y master alloy and Mg-10Mn master alloy as raw materials, after surface pretreatment (such as removal of dirt, scale, etc., the same as the following examples), according to the above objectives ingredients for batching;

[0048] 2) Melting: Set the furnace temperature to 700-730°C. When the furnace temperature rises to the predetermined temperature, put the pure Mg ingot preheated to 200°C into the crucible of the melting furnace. Add the pure Bi block at 50°C and the Mg-Y master alloy preheated to 200°C into the molten magnesium; then increase the melting temperature to 750-760°C and keep it warm for 10 minutes, then stir for 5 minutes and let stand for 5 minutes , add Mg-10Mn master alloy, keep it warm for 10 minutes, then stir for 5 minutes, lower th...

Embodiment 2

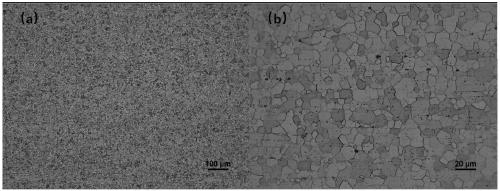

[0056] (1) design and select Mg-6.0Bi-3Y-0.08Mn (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method includes the following steps:

[0057] 1) Ingredients: Use pure Mg ingot, pure Bi block, Mg-30Y master alloy and Mg-10Mn master alloy as raw materials, after surface pretreatment (such as removal of dirt, scale, etc., the same as the following examples), according to the above objectives ingredients for batching;

[0058] 2) Melting: Set the furnace temperature to 700-730°C. When the furnace temperature rises to the predetermined temperature, put the pure Mg ingot preheated to 200°C into the crucible of the melting furnace. Add the pure Bi block at 50°C and the Mg-Y master alloy preheated to 200°C into the molten magnesium; then increase the melting temperature to 750-760°C and keep it warm for 10 minutes, then stir for 5 minutes and let stand for 5 minutes , add Mg-10Mn master alloy, keep it warm for 10 minutes, then stir for 5 minutes, lower th...

Embodiment 3

[0066] (1) The design selects the Mg-4.5Bi-2.3Y-0.05Mn (wt%) alloy composition ratio to form a magnesium alloy, and the preparation method comprises the following steps:

[0067] 1) Ingredients: Use pure Mg ingot, pure Bi block, Mg-30Y master alloy and Mg-10Mn master alloy as raw materials, after surface pretreatment (such as removal of dirt, scale, etc., the same as the following examples), according to the above objectives ingredients for batching;

[0068] 2) Melting: Set the furnace temperature to 700-730°C. When the furnace temperature rises to the predetermined temperature, put the pure Mg ingot preheated to 200°C into the crucible of the melting furnace. Add the pure Bi block at 50°C and the Mg-Y master alloy preheated to 200°C into the molten magnesium; then increase the melting temperature to 750-760°C and keep it warm for 10 minutes, then stir for 5 minutes and let stand for 5 minutes , add Mg-10Mn master alloy, keep it warm for 10 minutes, then stir for 5 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com