Nickel-based alloy production and processing technology

A processing technology, nickel-based alloy technology, applied in the field of nickel-based alloy production and processing technology, can solve the problems of uneven structural stability of nickel-based alloy components, affecting the quality and service life of use, poor surface wear resistance, etc., to reduce the local Accumulation, strong plasticity, quality reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

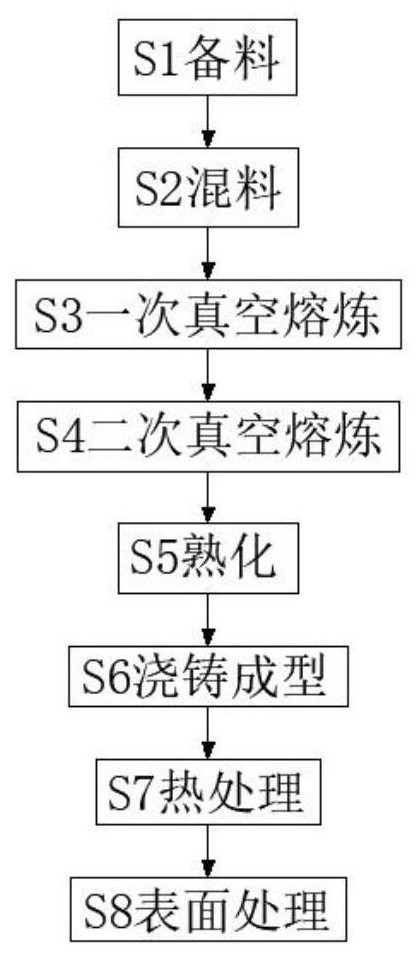

Method used

Image

Examples

Embodiment 1

[0068] Prepared by the above process, the nickel-based alloy weighs the following raw materials according to the percentage: Cr: 28.22%, Mo: 17.51%, Cu: 15.74%, Fe: 10.82%, Al: 9.88%, Si: 6.56%, Ni: 5.86%, W: 3.47%, Nb: 3.24%, Ti: 0.83%, In: 0.35%.

Embodiment 2

[0070] Prepared by the above process, the nickel-based alloy weighs the following raw materials according to the percentage: Cr: 27%, Mo: 16%, Cu: 14.5%, Fe: 10%, Al: 8.2%, Si: 5.5%, Ni: 4.5%, W: 2.5%, Nb: 2.8%, Ti: 0.75%, In: 0.3%.

Embodiment 3

[0072] Prepared by the above process, the nickel-based alloy weighs the following raw materials according to the percentage: Cr: 25.57%, Mo: 15.36%, Cu: 13.61%, Fe: 9.21%, Al: 7.25%, Si: 4.76%, Ni: 3.58%, W: 1.85%, Nb: 2.45%, Ti: 0.83%-0.68%, In: 0.35%-0.22%.

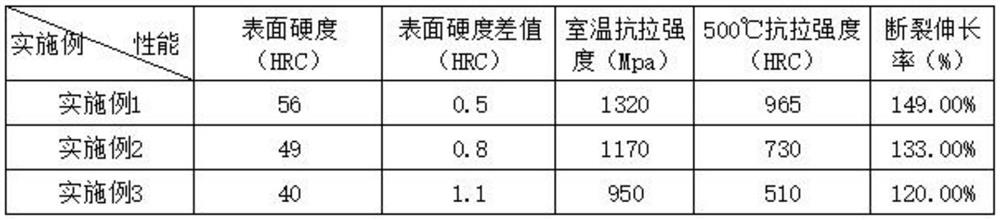

[0073] According to the above-mentioned 3 embodiments, the nickel-based alloy prepared by the above-mentioned process method is obtained in Table 1 after the performance test, as follows, wherein, the method for measuring the difference in surface hardness is: take 10 evenly on the surface of each nickel-based alloy block Point measurement of surface hardness, the difference between the measured maximum value and minimum value is the surface hardness difference of the corresponding embodiment:

[0074]

[0075] In summary, according to the production process of the present invention, it can be seen from the nickel-based alloys produced according to the percentage requirements of different raw materials that after bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com