High-weather-resistance low-smokiness and high-rigidity flame-retardant reinforced PP blending material and preparation method thereof

A low-smoke, high-rigidity technology, applied in the field of polymer materials, to achieve the effects of good self-extinguishing, short burning time and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

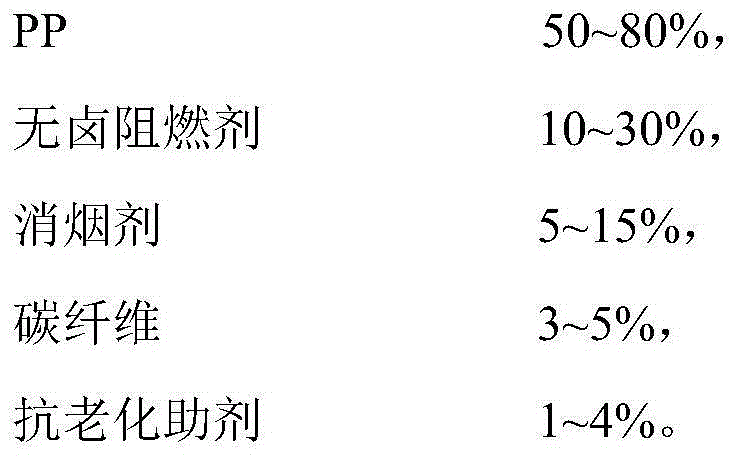

Method used

Image

Examples

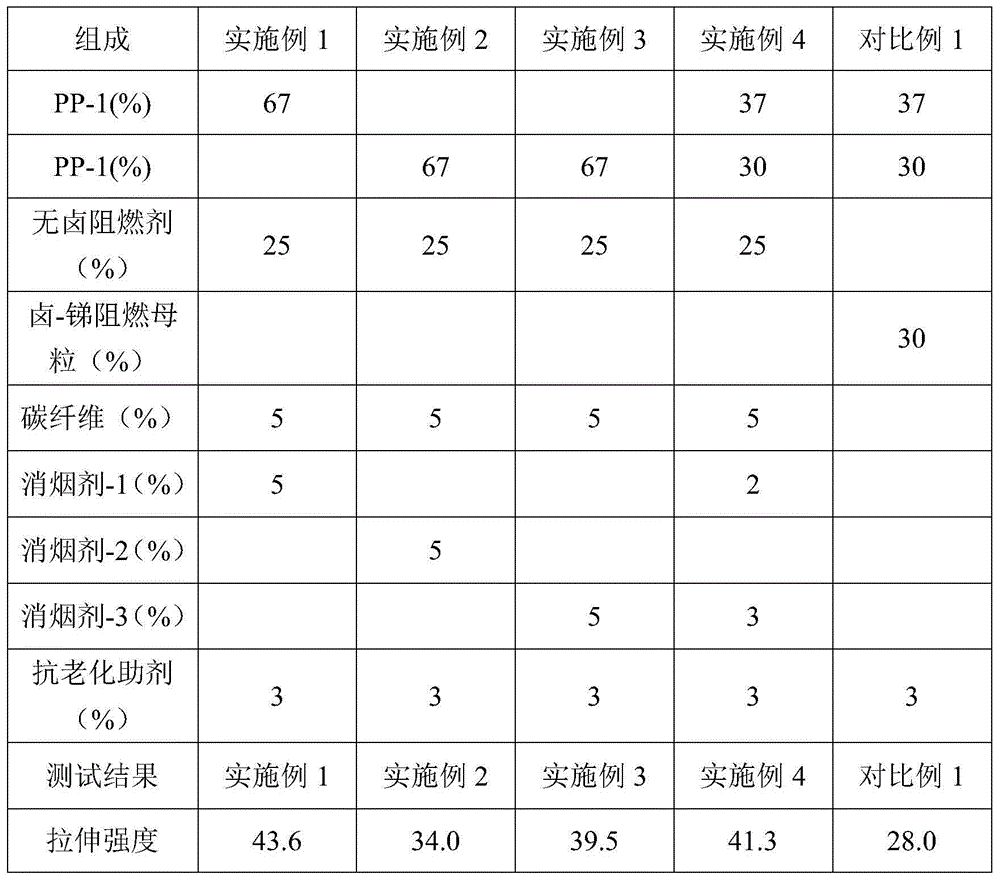

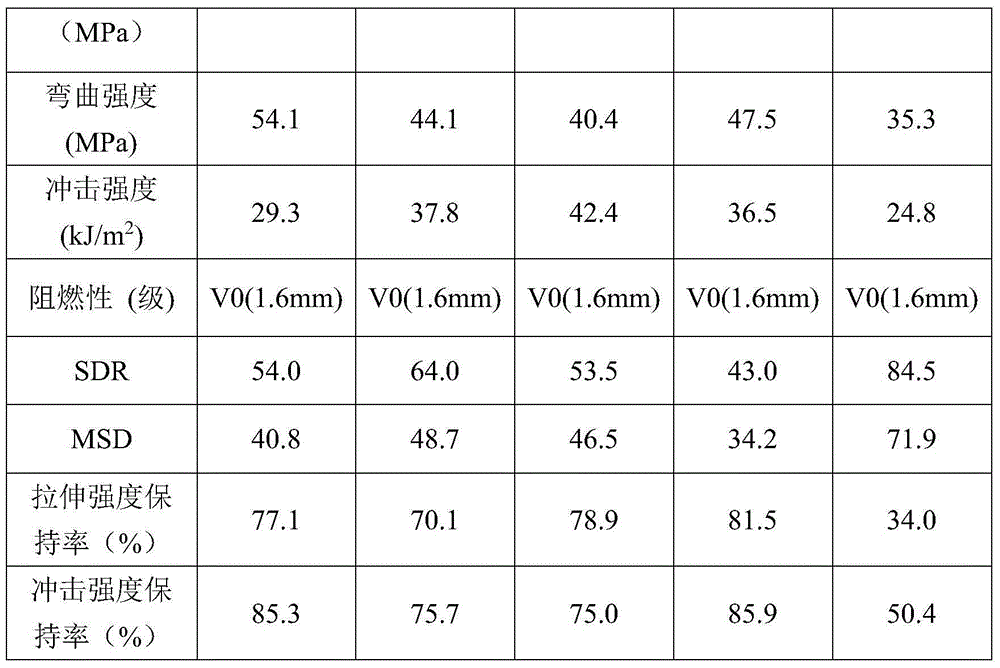

Embodiment 1

[0040] Soak 5g of carbon fiber in 1mol / L NaOH solution for 24 hours, take it out and filter it, put it in a muffle furnace, burn it at 600°C under aerobic conditions for 30 minutes, rinse it repeatedly with deionized water after cooling, and dry it The carbon fiber after surface activation treatment is obtained.

[0041] Weigh 67g of PP-1 resin, 25g of halogen-free flame retardant, 5g of carbon fiber, 5g of smoke suppressant-1, and 3g of anti-aging additive and put them into a high-speed mixer and mix them evenly. Put the obtained mixed raw material into the main feeding bin of twin-screw extrusion, and put it into the main barrel through the feeding screw. The diameter of the screw of the extruder is 35 mm, the length-to-diameter ratio L / D=36, and the temperature of each section of the main barrel is controlled. (From the feeding port to the nozzle outlet) at 185°C, 190°C, 195°C, 200°C, 210°C, 210°C, the speed of the host machine is 250 rpm, and it is obtained after melt extr...

Embodiment 2

[0043] Soak 5g of carbon fiber in 1mol / L NaOH solution for 24 hours, take it out and filter it, put it in a muffle furnace, burn it at 600°C under aerobic conditions for 30 minutes, rinse it repeatedly with deionized water after cooling, and dry it The carbon fiber after surface activation treatment is obtained.

[0044]Weigh 67g of PP-2 resin, 25g of halogen-free flame retardant, 5g of carbon fiber, 5g of smoke suppressant-2, and 3g of anti-aging additive and put them into a high-speed mixer and mix them evenly. Put the obtained mixed raw material into the main feeding bin of twin-screw extrusion, and put it into the main barrel through the feeding screw. The diameter of the screw of the extruder is 35 mm, the length-to-diameter ratio L / D=36, and the temperature of each section of the main barrel is controlled. (From the feeding port to the nozzle outlet) at 185°C, 190°C, 195°C, 200°C, 210°C, 210°C, the speed of the host machine is 250 rpm, and it is obtained after melt extru...

Embodiment 3

[0046] Soak 5g of carbon fiber in 1mol / L NaOH solution for 24 hours, take it out and filter it, put it into a muffle furnace, burn it at 800°C under aerobic conditions for 30 minutes, rinse it repeatedly with deionized water after cooling, and dry it The carbon fiber after surface activation treatment is obtained.

[0047] Weigh 67g of PP-2 resin, 25g of halogen-free flame retardant, 5g of carbon fiber, 5g of smoke suppressant-3, and 3g of anti-aging additive and put them into a high-speed mixer and mix them evenly. Put the obtained mixed raw material into the main feeding bin of twin-screw extrusion, and put it into the main barrel through the feeding screw. The diameter of the screw of the extruder is 35 mm, the length-to-diameter ratio L / D=36, and the temperature of each section of the main barrel is controlled. (From the feeding port to the nozzle outlet) at 185°C, 190°C, 195°C, 200°C, 210°C, 210°C, the speed of the host machine is 250 rpm, and it is obtained after melt ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com