Asphalt flame retardant, preparation method and application

A flame retardant and inorganic flame retardant technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problem that inorganic flame retardants cannot achieve good flame retardant effects, poor economic and environmental benefits, and flame retardant. The problem of large amount of asphalt smoke, etc., can improve the high temperature performance, reduce the impact, and shorten the burning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

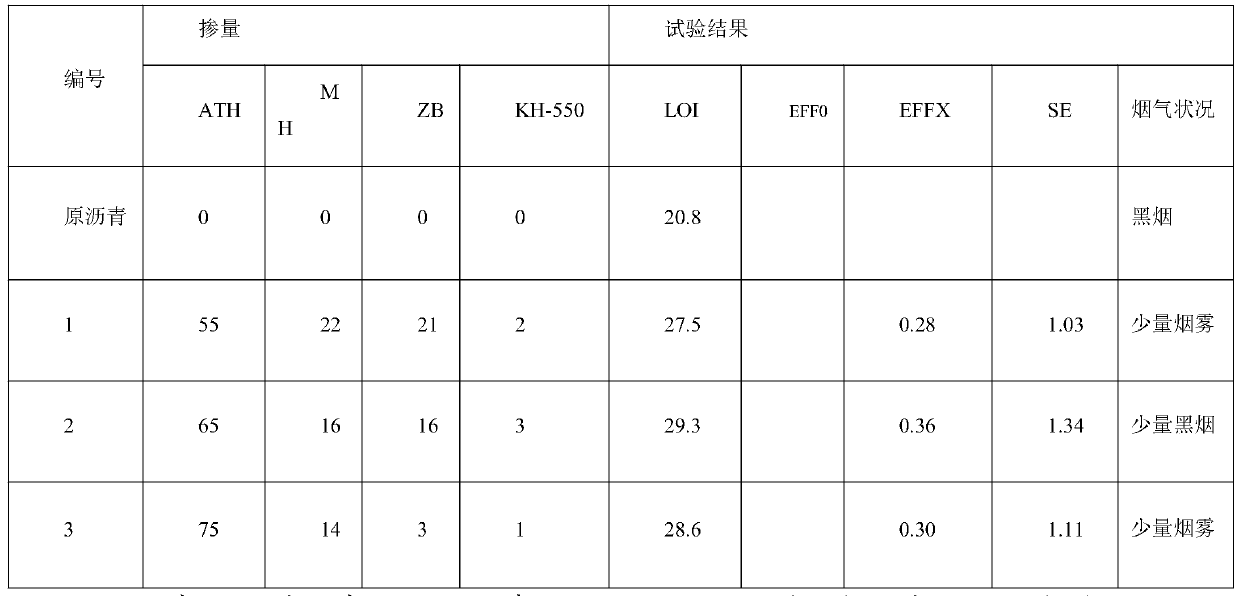

Embodiment 1

[0027] The asphalt flame retardant in this embodiment is composed of raw materials by weight: 55 parts of aluminum hydroxide, 22 parts of magnesium hydroxide, 21 parts of zinc borate, and 2 parts of surface modifier.

[0028] The preparation method of the asphalt flame retardant of this embodiment is as follows: the three raw materials of aluminum hydroxide, magnesium hydroxide, and zinc borate are placed in a closed high-speed mixing device in proportion, sheared for about 10 minutes, and then mixed at a stirring speed of 700r / min Heating in a water bath with a surface modifying agent, refluxing for a period of time, filtering while hot after the reaction, drying the filter cake, and pulverizing to obtain the asphalt flame retardant powder.

Embodiment 2

[0030] The asphalt flame retardant of this embodiment is composed of the following raw materials by weight: 65 parts of aluminum hydroxide, 16 parts of magnesium hydroxide, 16 parts of zinc borate, and 3 parts of surface modifier.

[0031] The preparation method of the asphalt flame retardant of this embodiment is as follows: the three raw materials of aluminum hydroxide, magnesium hydroxide, and zinc borate are placed in a closed high-speed mixing device in proportion according to the weight ratio, sheared for about 10 minutes, and then heated at 700r Heat the surface modifier in a water bath at a stirring speed of 1 / min, reflux for a period of time, filter while hot after the reaction, dry the filter cake, and pulverize to obtain asphalt flame retardant powder.

Embodiment 3

[0033] The asphalt flame retardant of this embodiment is composed of the following raw materials by weight: 75 parts of aluminum hydroxide, 14 parts of magnesium hydroxide, 10 parts of zinc borate, and 1 part of surface modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com