High-efficiency mixed abrasive chemical mechanical polishing solution for sapphire substrate

A sapphire substrate, chemical-mechanical technology, applied in polishing compositions containing abrasives, etc., can solve problems such as reducing product reliability, health hazards, and increasing costs, and achieves stable pH value, fast polishing rate, and uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

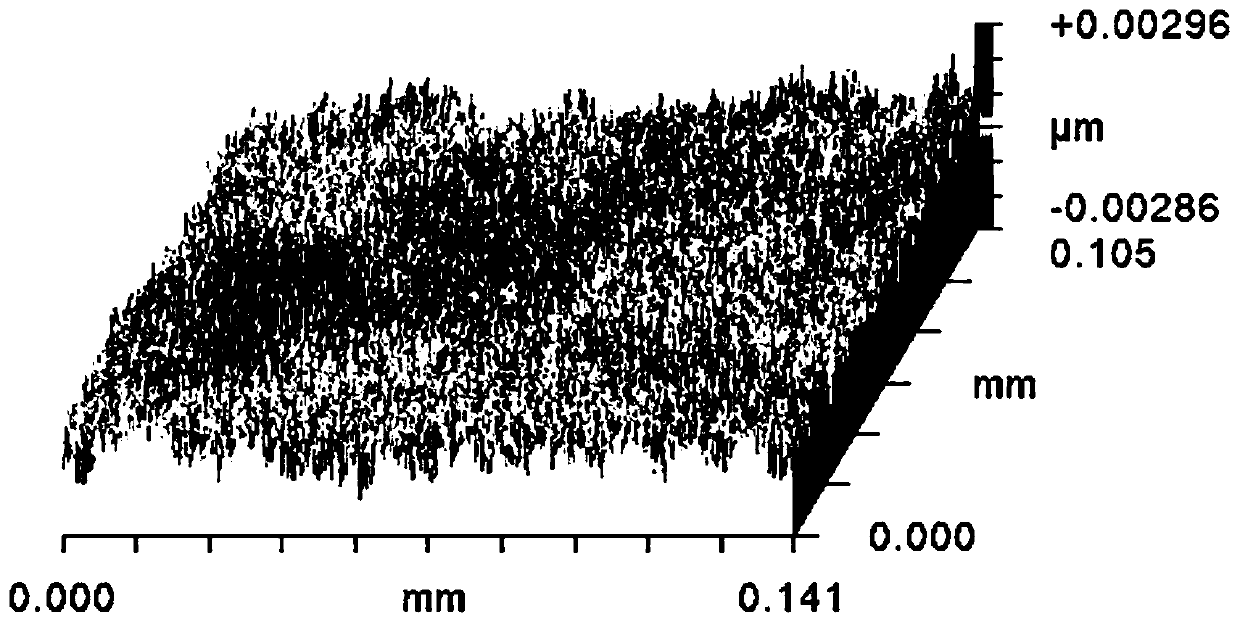

[0028] The main components and content of the polishing liquid: the abrasive is 25nm and 90nm silicon oxide abrasives with the same solid content mixed according to the weight ratio of 3:1, the content is 10%; the surfactant is polyoxyethylene lauryl ether, the content is 0.5%; The chelating agent is sorbitol, with a content of 0.5%, and the pH regulator is aminomethyl propanol, and the adjusted pH is 10.5.

[0029] The surface roughness Ra value of the polished sapphire substrate is 0.530nm, the rms value is 0.661nm, and the PV value is 5.814nm (see figure 2 ), the material removal rate is 6.78μm / h. .

Embodiment 2

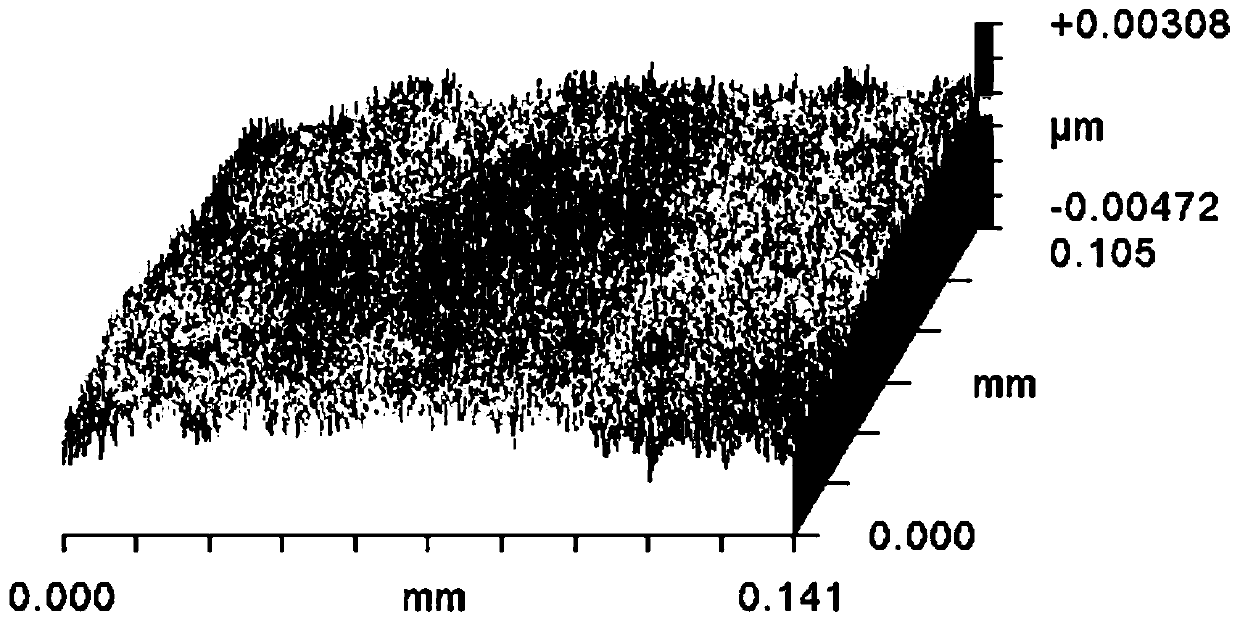

[0031] The main components and content of the polishing liquid: the abrasive is silicon oxide abrasive, the particle size is 25nm, and the content is 10%; the surfactant is polyoxyethylene lauryl ether, the content is 0.5%; the chelating agent is sorbitol, the content is 0.5%, The pH regulator is aminomethyl propanol, and the pH is adjusted to be 10.5.

[0032] The surface roughness Ra value of the polished sapphire substrate is 0.606nm, the rms value is 0.764nm, and the PV value is 7.801nm (see image 3 ), the material removal rate is 3.18μm / h.

Embodiment 3

[0034] The main components and content of the polishing liquid: the abrasive grain is silicon oxide abrasive grain, the particle size is 90nm, and the content is 10%; the surfactant is polyoxyethylene lauryl ether, the content is 0.5%; the chelating agent is sorbitol, the content is 0.5% %, the pH regulator is aminomethylpropanol, and the pH adjustment is 10.5.

[0035] The surface roughness Ra value of the polished sapphire substrate is 0.643nm, the rms value is 0.827nm, and the PV value is 7.198nm (see Figure 4 ), the material removal rate is 4.86μm / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com