Tungstate-based catalytic material and application thereof in hydrogen peroxide production through water oxidation

A catalytic material, hydrogen peroxide technology, applied in the field of electrochemistry, can solve problems such as the inability to produce hydrogen peroxide cheaply, and achieve excellent market application prospects, low energy consumption, and high commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

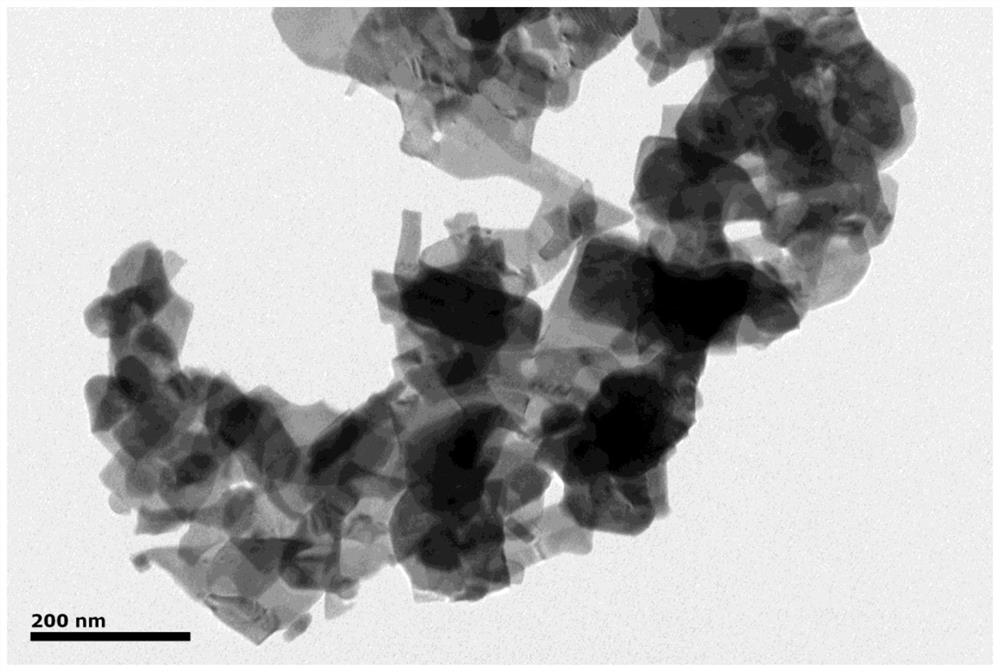

[0060] A kind of catalytic material based on tungstate, the concrete preparation method is as follows:

[0061] In this experiment, the catalytic material based on tungstate, Bi 2 WO 6 One-component tungstate catalyst. Specifically, 1.5mmol Bi(NO 3 ) 3 ·5H 2 The mixture of O and 1.5mmol citric acid was dissolved in 1mol / L dilute nitric acid to form a transparent solution; meanwhile, 0.725mmol Na 2 WO 4 2H 2 O and 0.6g PVP were dissolved in 30mL of deionized water; then the above two solutions were mixed together to obtain a mixed solution, and the pH of the mixed solution was adjusted to 7 with a certain amount of NaOH solution, and the resulting clear solution was added to 50mL of poly In the PTFE-lined autoclave, the maximum can reach 80% of the total volume; the high-pressure steam of the PTFE-lined autoclave is sealed in a stainless steel tank, and heated to 180°C for hydrothermal reaction for 12 hours; the final product is distilled water washed several times, and...

Embodiment 2

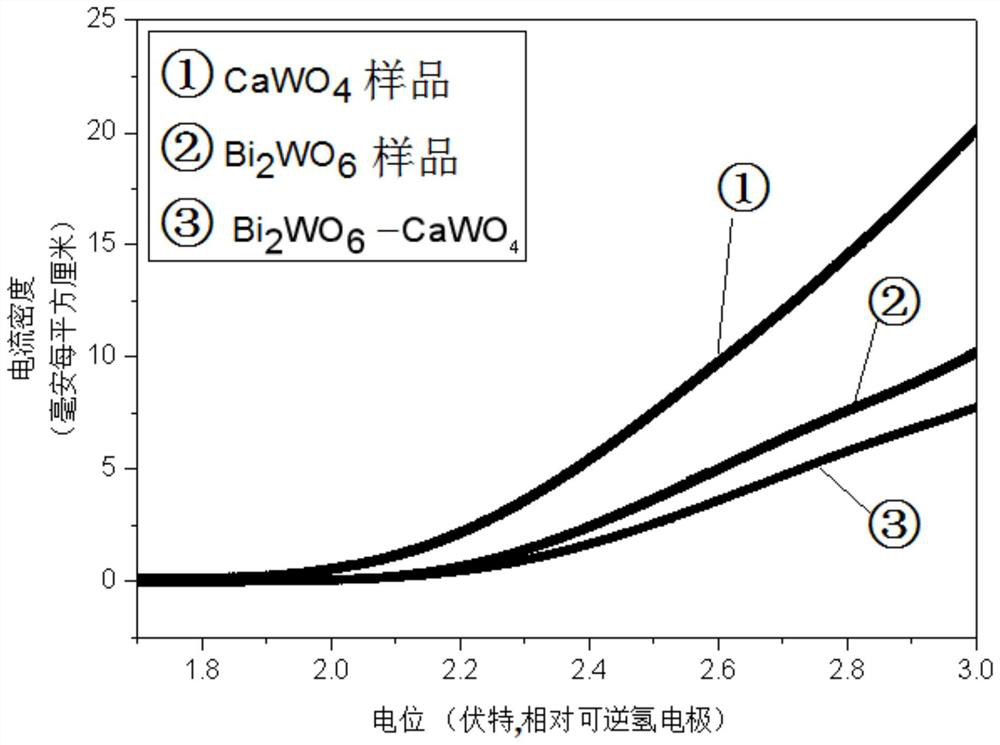

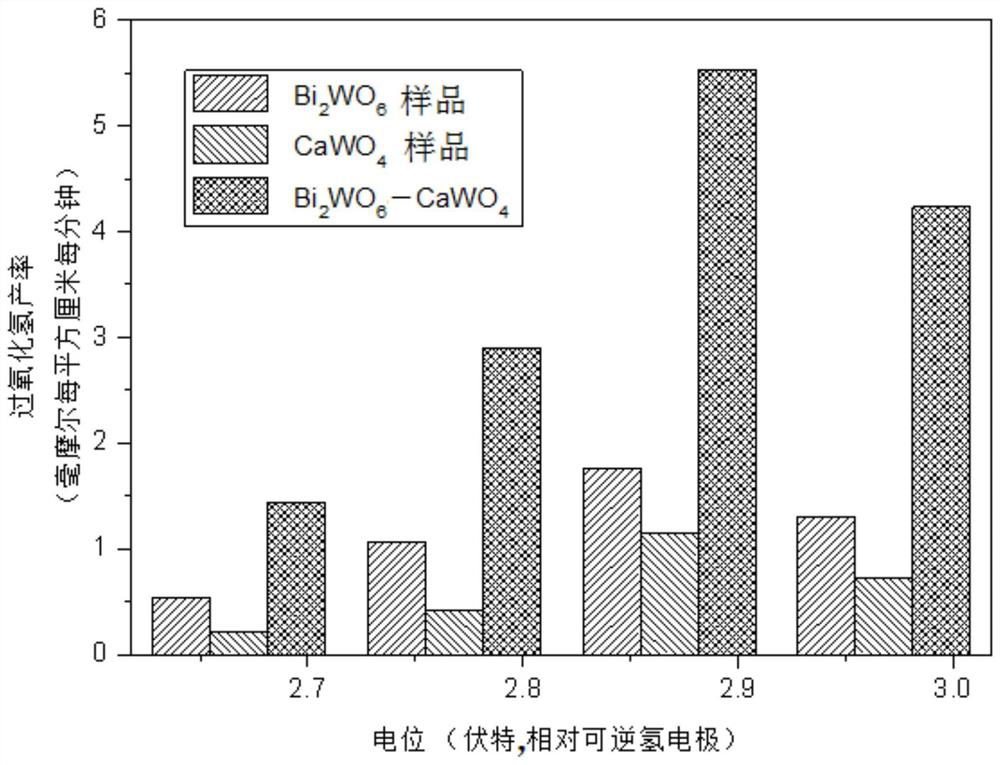

[0063] With the Bi prepared in Example 1 2 WO 6 The sample is used as a catalyst to test its performance in water oxidation to produce hydrogen peroxide. Specifically, the three-electrode electrolysis device includes an electrolysis cell, electrodes, electrolyte solution, and diaphragm. Described electrode comprises working electrode, opposite electrode and reference electrode, diaphragm selects proton exchange membrane nafion117 for use, and electrolytic cell is separated into cathode area and anode area by proton exchange membrane nafion117, and anode area is made of FTO conductive glass (SnO2 conductive glass doped with fluorine ) is the working electrode, and the catalyst is Bi 2 WO 6 For the sample, a platinum plate is used as the counter electrode in the cathode area, and a silver / silver chloride electrode is used as the reference electrode. A saturated potassium bicarbonate solution is injected into the electrolytic cell as the electrolyte solution, and the potential ...

Embodiment 3

[0065] A kind of catalytic material based on tungstate, the concrete preparation method is as follows:

[0066] In this experiment, the catalytic material based on tungstate, that is, CaWO, was synthesized by using sodium tungstate, calcium nitrate, citric acid, nitric acid, PVP, and sodium hydroxide as raw material reagents by hydrothermal synthesis. 4 One-component tungstate catalyst. Specifically, 1 mmol Ca(NO 3 ) 2 4H 2 The mixture of O and 1mmol citric acid was dissolved in 1mol / L dilute nitric acid to form a transparent solution; at the same time, 1mmol Na 2 WO 4 2H 2 O and 0.6g PVP were dissolved in 30mL of deionized water; then the above two solutions were mixed together to obtain a mixed solution, and the pH of the mixed solution was adjusted to 7 with a certain amount of NaOH solution, and the resulting clear solution was added to 50mL of poly In the PTFE-lined autoclave, the maximum can reach 80% of the total volume; the high-pressure steam of the PTFE-lined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com