Sludge and straw mixed squeezing treatment method and device

A treatment method and sludge technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of secondary pollution, low utilization efficiency, long time consumption, etc. Achieve the effect of increasing calorific value, low moisture content and reducing affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

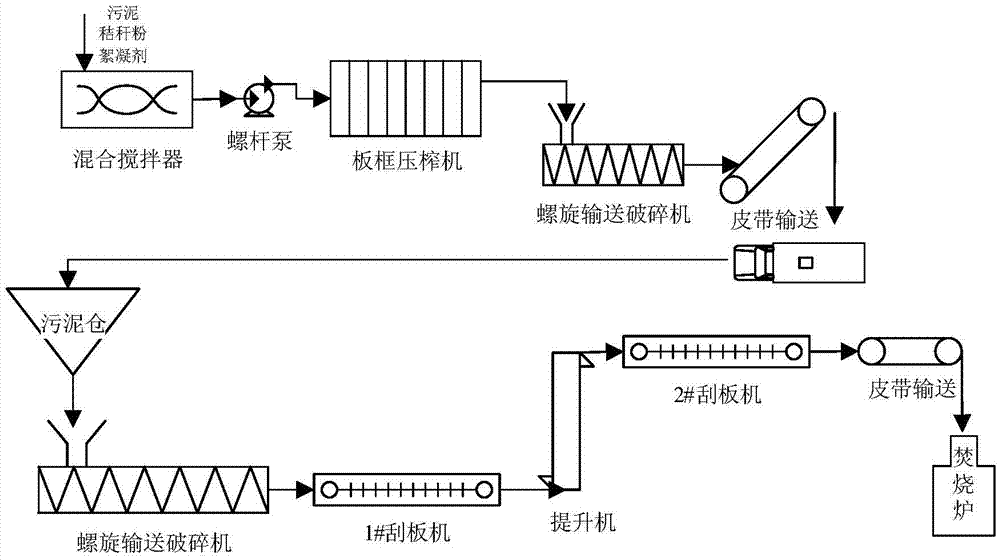

[0047] In order to overcome the problems existing in the prior art, the present invention provides an economical, efficient and environmentally friendly technology for mixing and pressing sludge and agricultural waste straw to produce fuel. The core of the method is that the sludge is mixed with the crushed straw powder, and then subjected to deep dehydration in a plate and frame press, and the mud cake after deep dehydration is used for co-incineration with garbage. On the one hand, the moisture content of the sludge is further reduced to 50-55%, on the other hand, the agricultural waste straw is effectively used to realize the resource utilization of the sludge and straw.

[0048] The method for mixing and pressing sludge and agricultural waste straw according to the present invention includes:

[0049] Step S1: Pretreating the sludge to remove part of the water in the sludge;

[0050] Step S2: crushing the agricultural waste straw to the target particle size, and mixing it...

Embodiment 2

[0068] In a certain urban sewage treatment plant, the scale of sewage treatment is 40,000 tons / day, and the sludge output from the secondary sedimentation tank (with a moisture content of 99%) is 480 tons / day. The remaining sludge in the secondary settling tank was filtered through a belt filter press. The flocculant was commercially available PAM, and the dosage was 0.5% by mass of the absolute dry weight of the sludge. 82%, the belt filter press mud output is 26.7 tons / day (moisture content 82%).

[0069] The sludge treated by the belt filter press enters the sludge and straw mixed press incineration system, and the following three processes are carried out:

[0070] (1) The straw is broken into 20mm with a crusher, and the straw powder, flocculant and sludge with a moisture content of 82% are evenly stirred and mixed in a mixer. 20% by mass of the dry weight, the flocculant is polyaluminum chloride, and the dosage is 2% by mass (calculated as 80%);

[0071] (2) The unifor...

Embodiment 3

[0074] In a certain urban sewage treatment plant, the scale of sewage treatment is 100,000 tons / day, and the sludge output from the secondary settling tank (with a moisture content of 99%) is 1,200 tons / day. The remaining sludge in the secondary settling tank is filtered through a belt filter press. The flocculant is commercially available PAM, and the dosage is 0.3% by mass of the absolute dry weight of the sludge. 80% or so, then the mud output of the belt filter press is 60 tons / day (calculated with a moisture content of 80%).

[0075] The sludge treated by the belt filter press enters the sludge and straw mixed press incineration system, and the following three processes are carried out:

[0076] (1) The straw is broken into 25mm with a crusher, and the straw powder, flocculant and sludge with a moisture content of 82% are uniformly stirred and mixed in a mixer. 10% by mass of the dry weight, the flocculant is polyaluminum chloride, and the dosage is 3% by mass (80%);

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com