Environment-friendly liquid nitrogen iced corpse processing device and method

A corpse treatment, green and environmental protection technology, applied in the field of corpse treatment, can solve problems such as environmental pollution, health hazards of staff, unfavorable environmental protection, etc., and achieve the effect of short burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

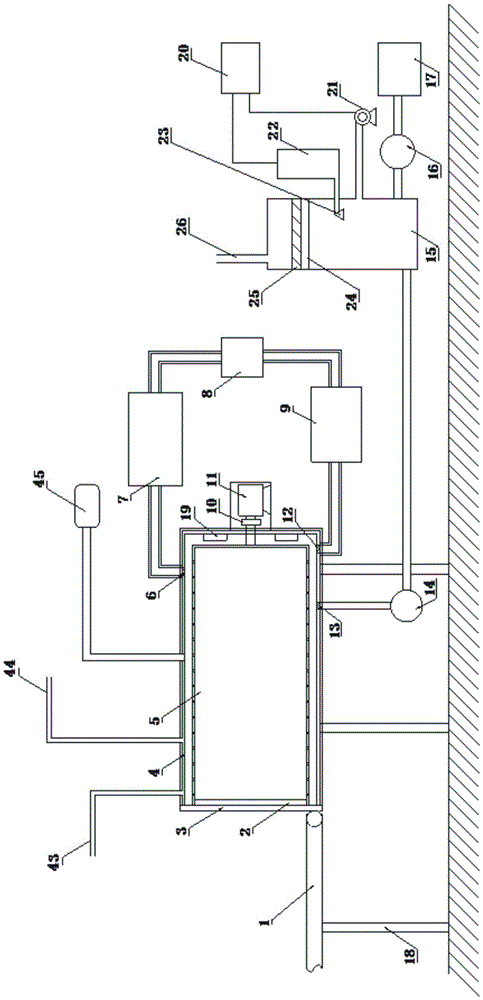

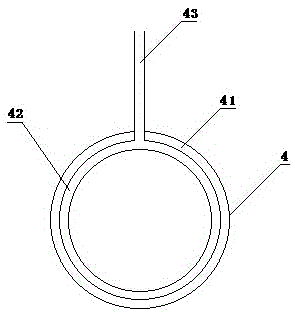

[0026] see Figure 1-3 , a green and environmentally friendly liquid nitrogen ice burial corpse processing device, including a conveyor belt 1, a processing bin 4, a liquid nitrogen storage tank 7, a liquid nitrogen purification device 8, and a liquid nitrogen recovery tank 9; On the left side, the left side of the processing chamber 4 has an opening, and the opening is provided with an electric lifting airtight door 3. When working, the electric lifting airtight door 3 is opened, and the corpse is sent to the processing chamber 4 through the conveyor belt 1, and then the electric lifting airtight door 3 is closed. The processing bin 4 is sealed for subsequent processing; the processing bin 4 is provided with a drum 5 with an opening on the left side of the drum 5, and a second layer of sealed door 2 is provided at the opening, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com