Circulating fluidized bed boiler flue gas desulfurizing system and treatment method thereof

A circulating fluidized bed and boiler flue gas technology, applied in the field of flue gas purification, to eliminate the influence of temperature changes and atmosphere on the sulfur fixation reaction and its products, improve the sulfur fixation rate, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

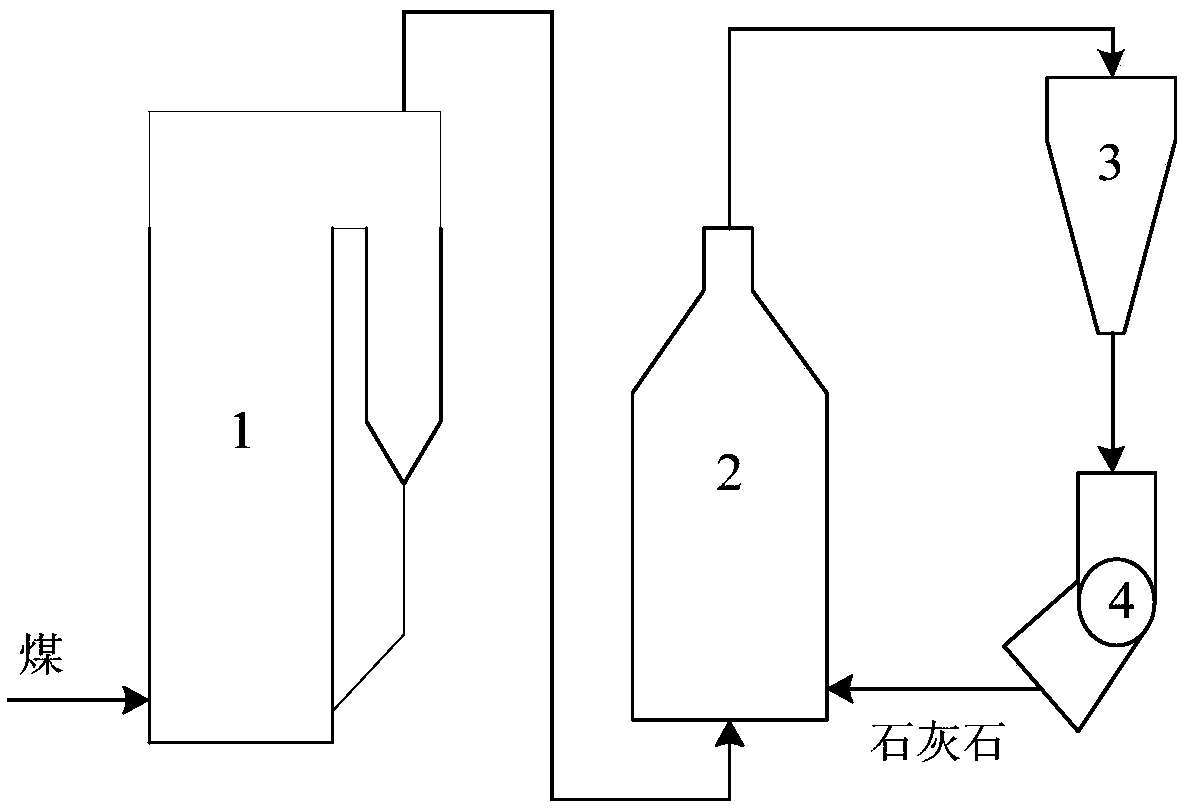

[0039] This embodiment provides a circulating fluidized bed boiler flue gas desulfurization system, the structural diagram of the system is as follows figure 1 As shown, it includes a circulating fluidized bed boiler 1 and a desulfurization fluidized bed 2, the flue gas outlet of the circulating fluidized bed boiler 1 is connected to the gas inlet provided at the bottom of the desulfurization fluidized bed 2, and the desulfurization fluidized bed 2 The bottom is provided with a desulfurizer inlet.

[0040] The system also includes a separator 3 and a feeder 4, the material outlet at the top of the desulfurization fluidized bed 2 is connected to the material inlet of the separator 3, the separator 3 includes a flue gas outlet and a material outlet, and the separator The material outlet of the device 3 is connected with the material inlet of the feeder 4, and the material outlet of the feeder 4 is connected with the desulfurizing agent inlet at the bottom of the desulfurization ...

Embodiment 2

[0042] This embodiment provides a method for flue gas desulfurization of a circulating fluidized bed boiler, which is carried out using the system in Embodiment 1, and includes the following steps:

[0043](1) Flue gas with a temperature of 900°C generated by coal combustion enters the desulfurization fluidized bed 2 and reacts with the desulfurizing agent limestone, the particle size of which is 0.4mm;

[0044] (2) The product after the reaction in step (1) is subjected to gas-solid centrifugation, and 99 wt% of the obtained solid limestone is returned to step (1) to continue the reaction.

[0045] In this embodiment, the high-temperature flue gas provides heat for the decomposition of limestone, and the flue gas desulfurization is transferred to the circulating fluidized bed boiler 1. The desulfurization efficiency reaches 97%, and the utilization rate of desulfurizer reaches 70%.

Embodiment 3

[0047] This embodiment provides a method for flue gas desulfurization of a circulating fluidized bed boiler. The method is carried out using the system in Embodiment 1, with reference to the method in Embodiment 2, the only difference is that the temperature of the flue gas in step (1) is At 880° C., the particle size of limestone is 0.1 mm, and the return ratio of limestone in step (2) is 99.4 wt %.

[0048] In this embodiment, the high-temperature flue gas provides heat for the decomposition of limestone, and the flue gas desulfurization is transferred to the circulating fluidized bed boiler 1. The desulfurization efficiency reaches 96%, and the utilization rate of desulfurizer reaches 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com