Patents

Literature

148 results about "Niobium pentaoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

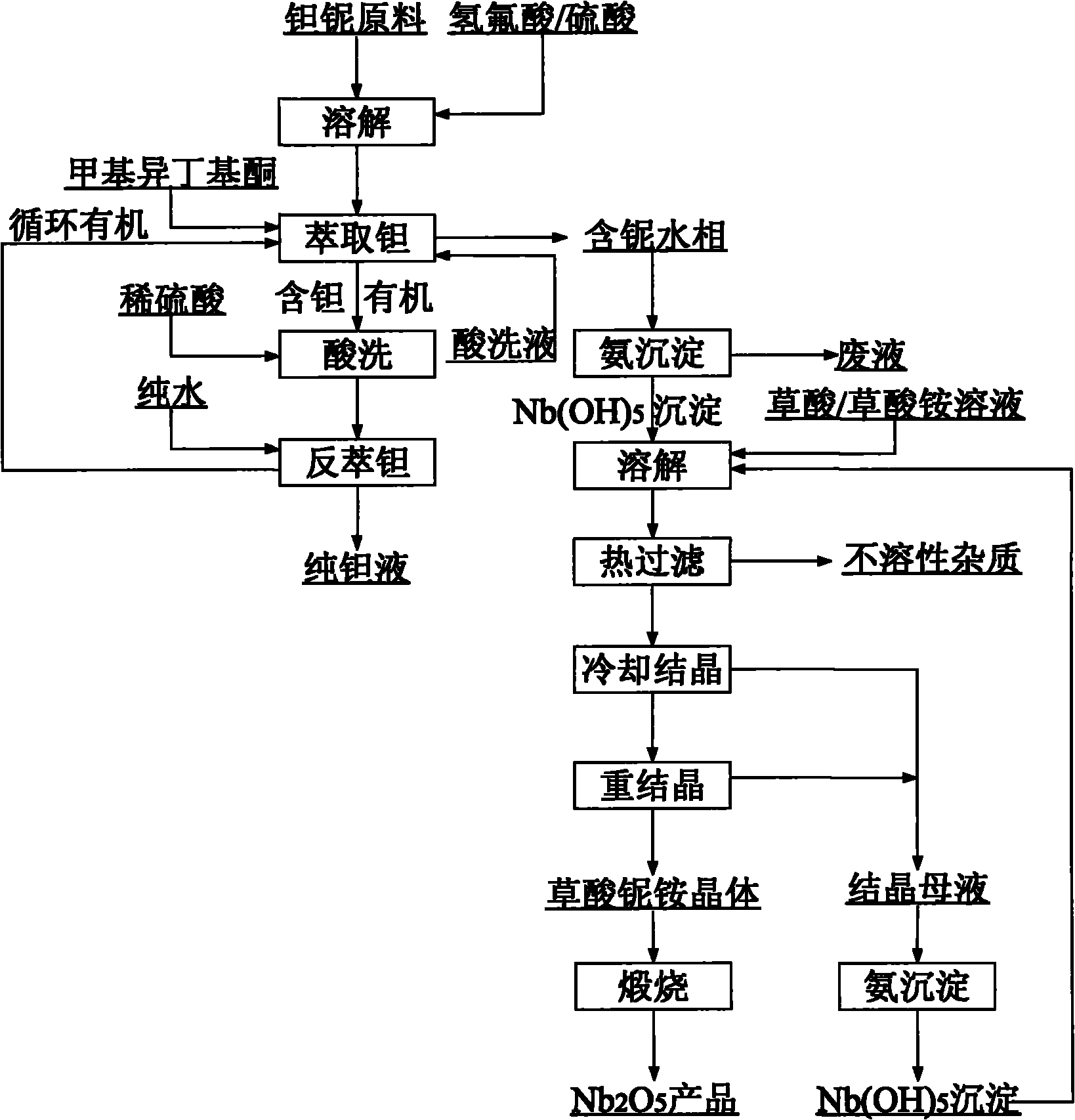

Method for separating tantalum and niobium

InactiveCN101955228AReduce concentrationReduce productionTantalum compoundsNiobium compoundsCoordination complexAmmonium oxalate

The invention relates to a method for separating tantalum and niobium from a raw material containing the tantalum and the niobium, comprising the following steps: dissolving the raw material containing the tantalum and the niobium by utilizing hydrofluoric acid or the mixing solution of the hydrofluoric acid and sulfuric acid to obtain the solution containing tantalum and niobium fluorine coordination compounds; extracting the tantalum by utilizing methyl isobutyl ketone to obtain a tantalum-containing organic phase and a niobium-containing aqueous phase; washing the tantalum-containing organic phase by dilute sulphuric acid, and performing back-extracting by pure water to obtain the pure tantalum liquid; precipitating the niobium-containing aqueous phase to obtain the Nb (OH)5 precipitation; dissolving the obtained Nb (OH)5 precipitation by utilizing an oxalic acid and ammonium oxalate mixing solution to obtain an oxalic acid niobium ammonium solution; carrying out hot filtering, crystallizing, and recrystallizing process to obtain the oxalic acid niobium ammonium crystal; and calcining the crystal to obtain the pure niobium pentaoxide. The method can realize extraction and separation of the tantalum and the niobium at low hydrofluoric acid concentration, and solves the problems that a large amount of fluorine-containing waste liquid and waste residue are generated in the extracting and separating process at the high hydrofluoric acid concentration, and F content in the final product is higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

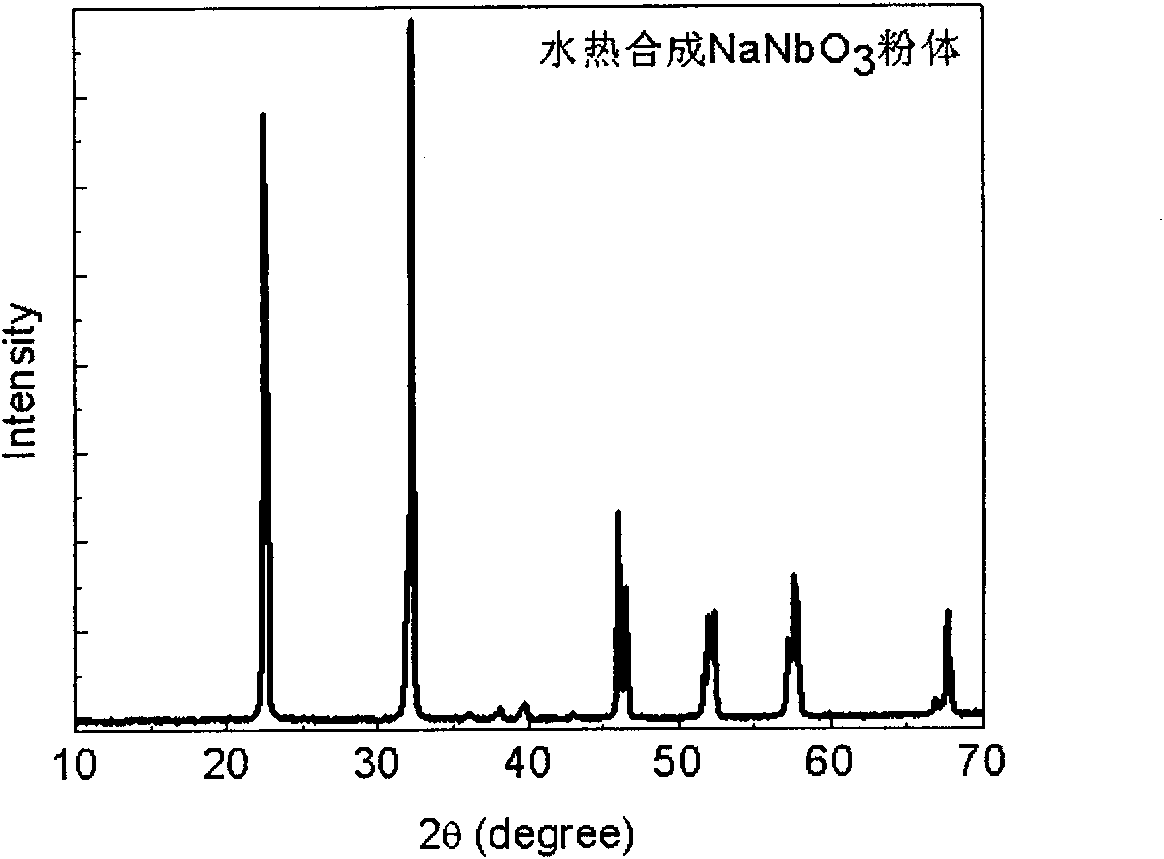

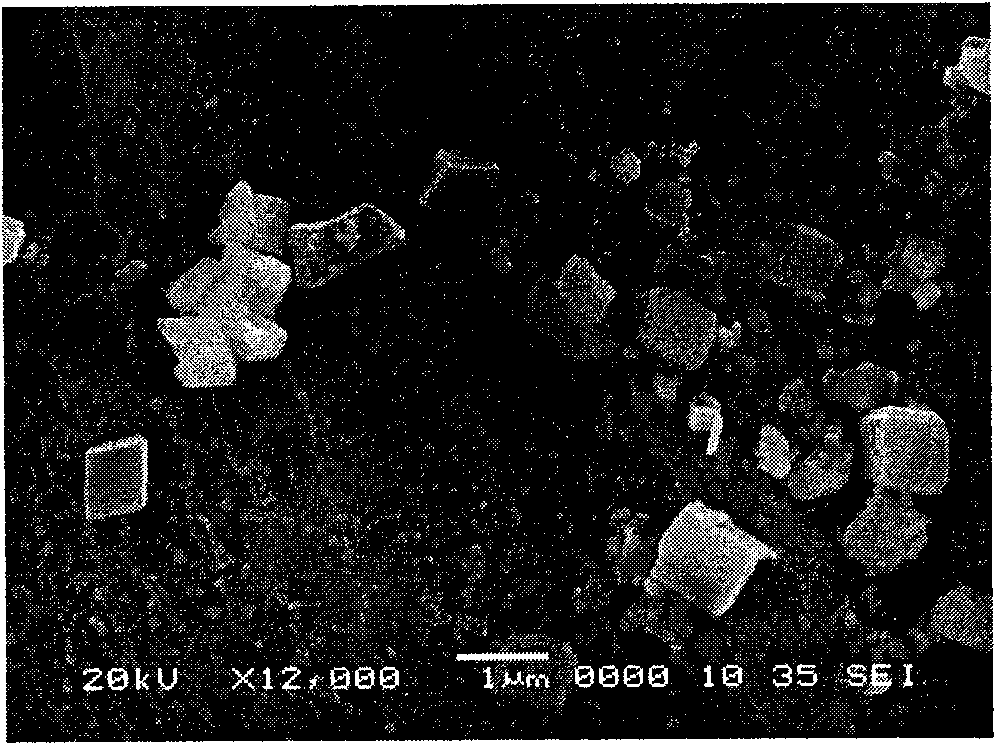

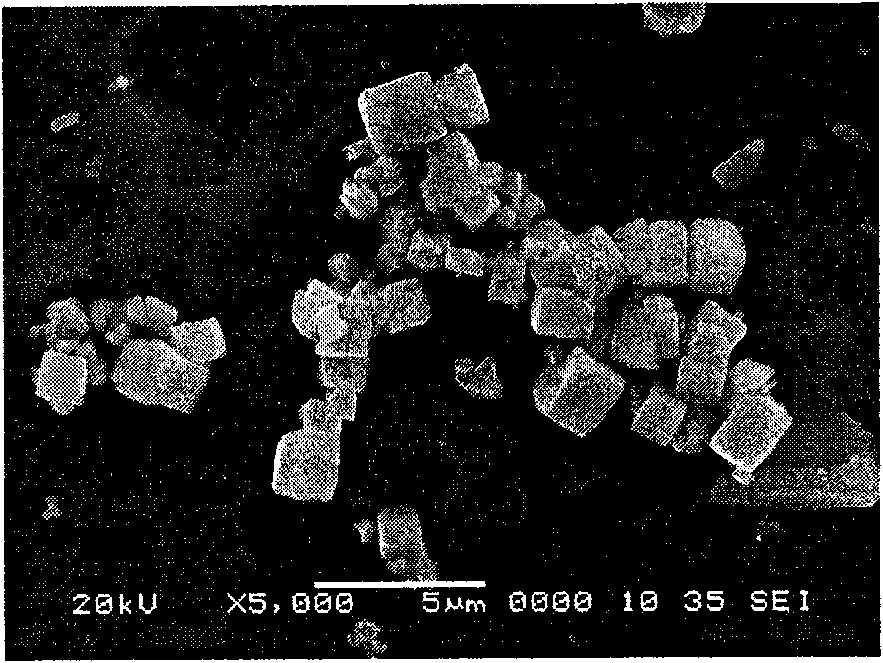

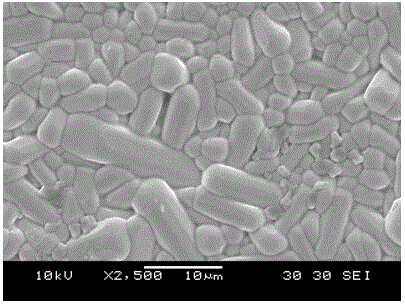

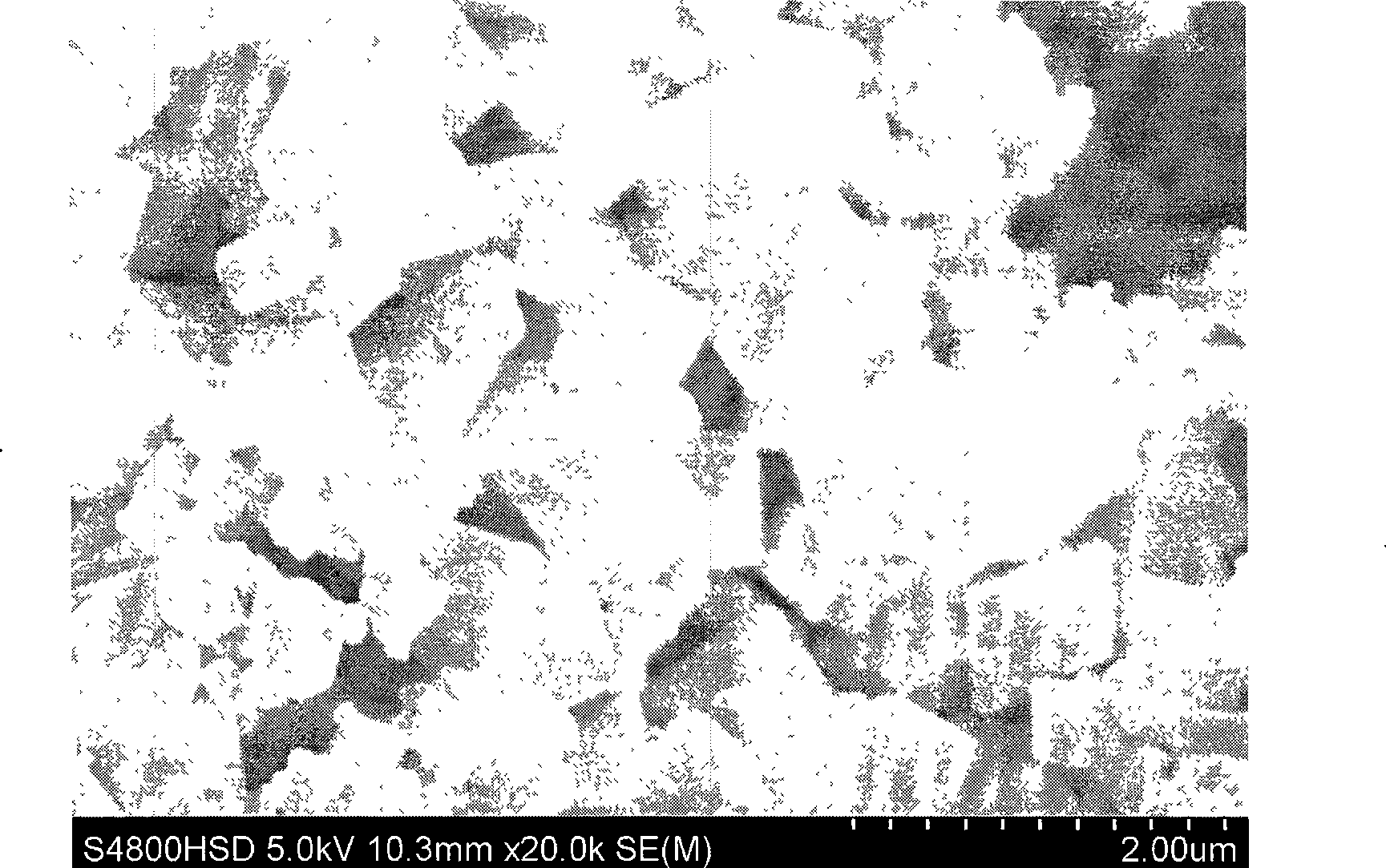

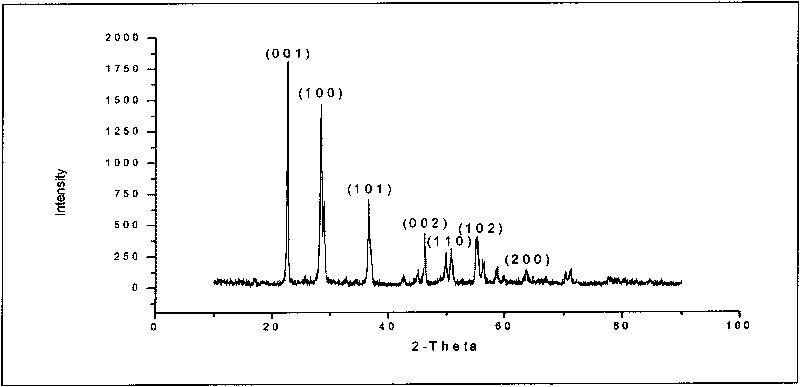

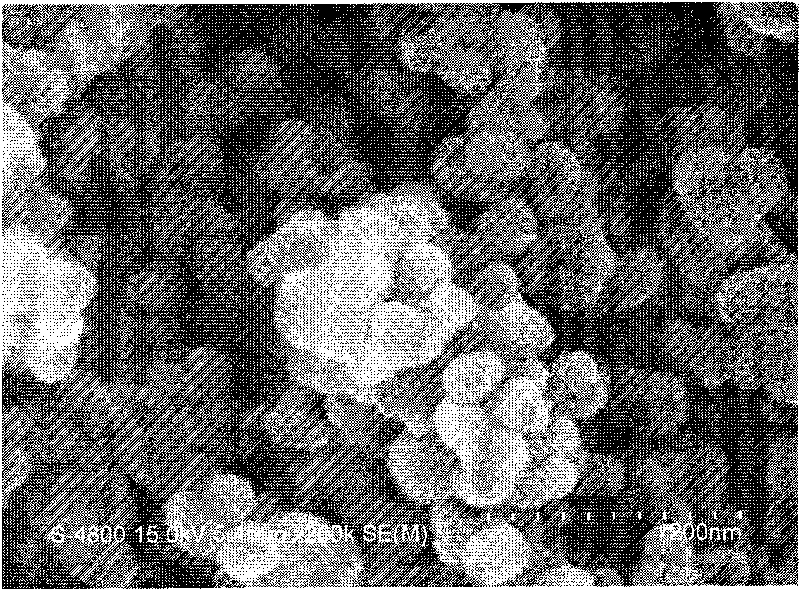

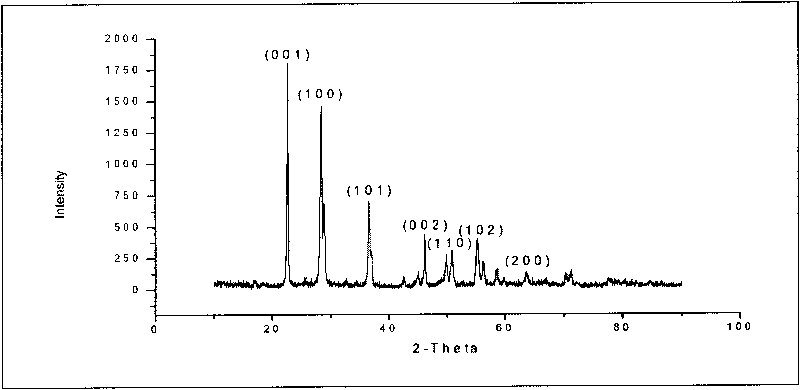

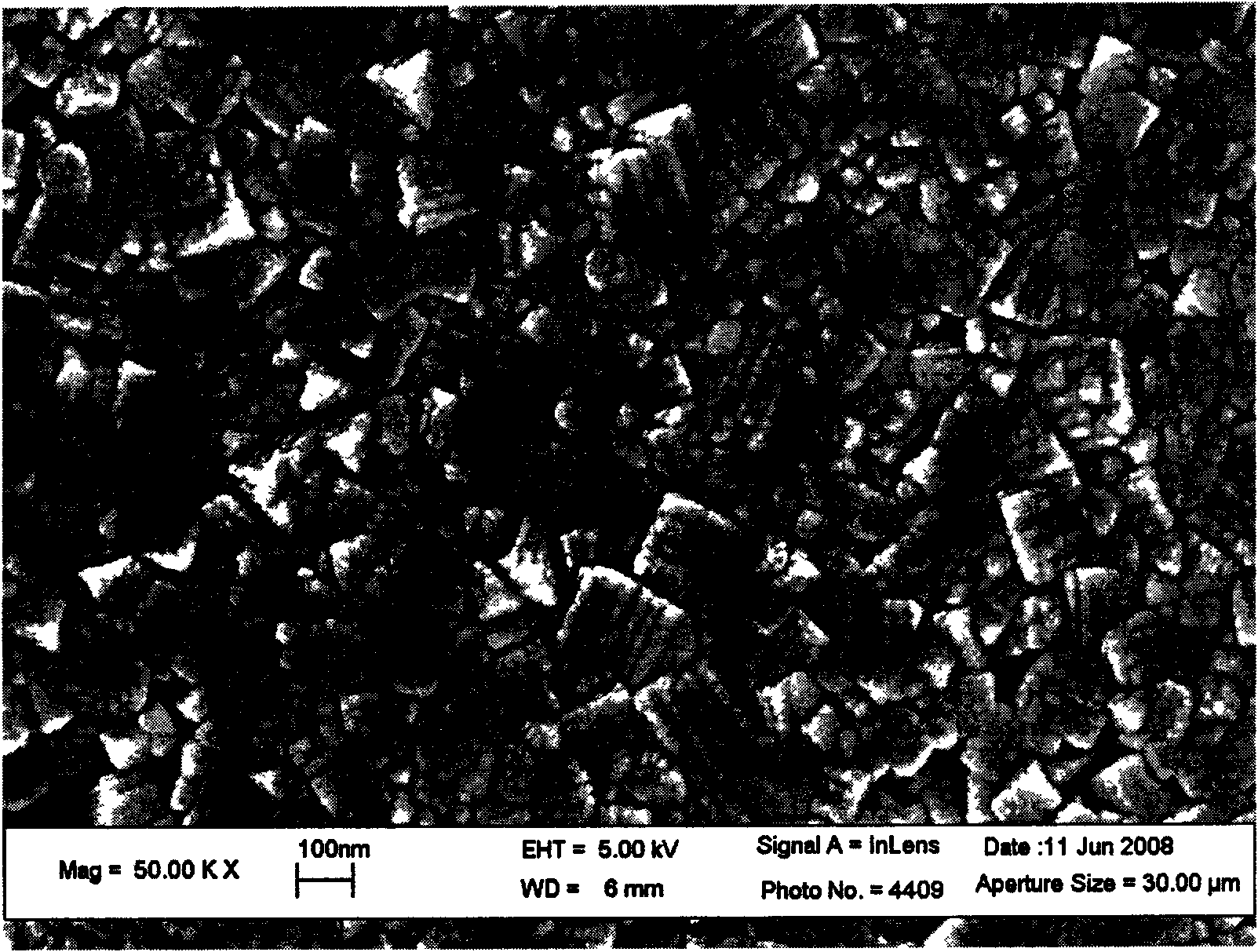

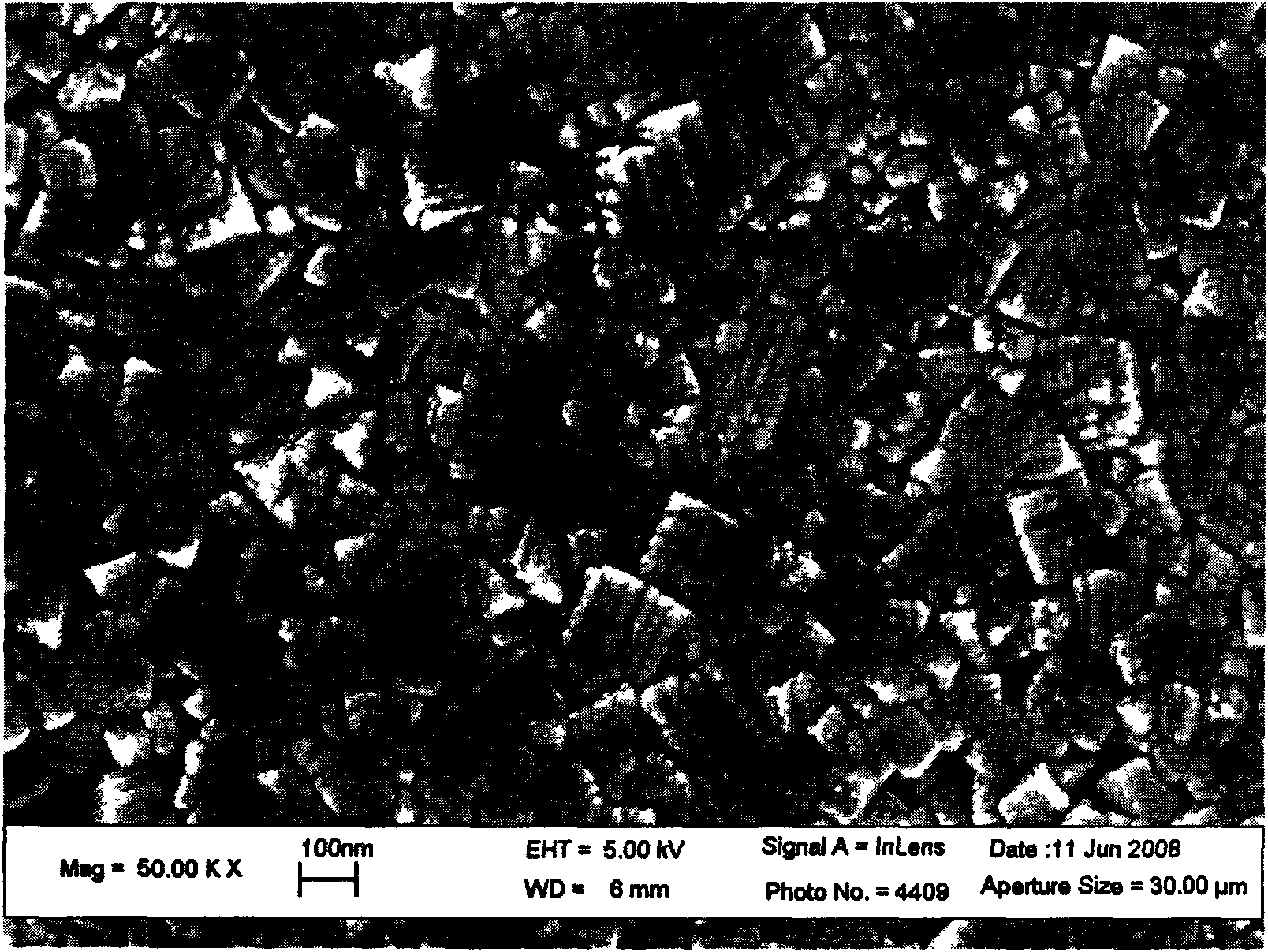

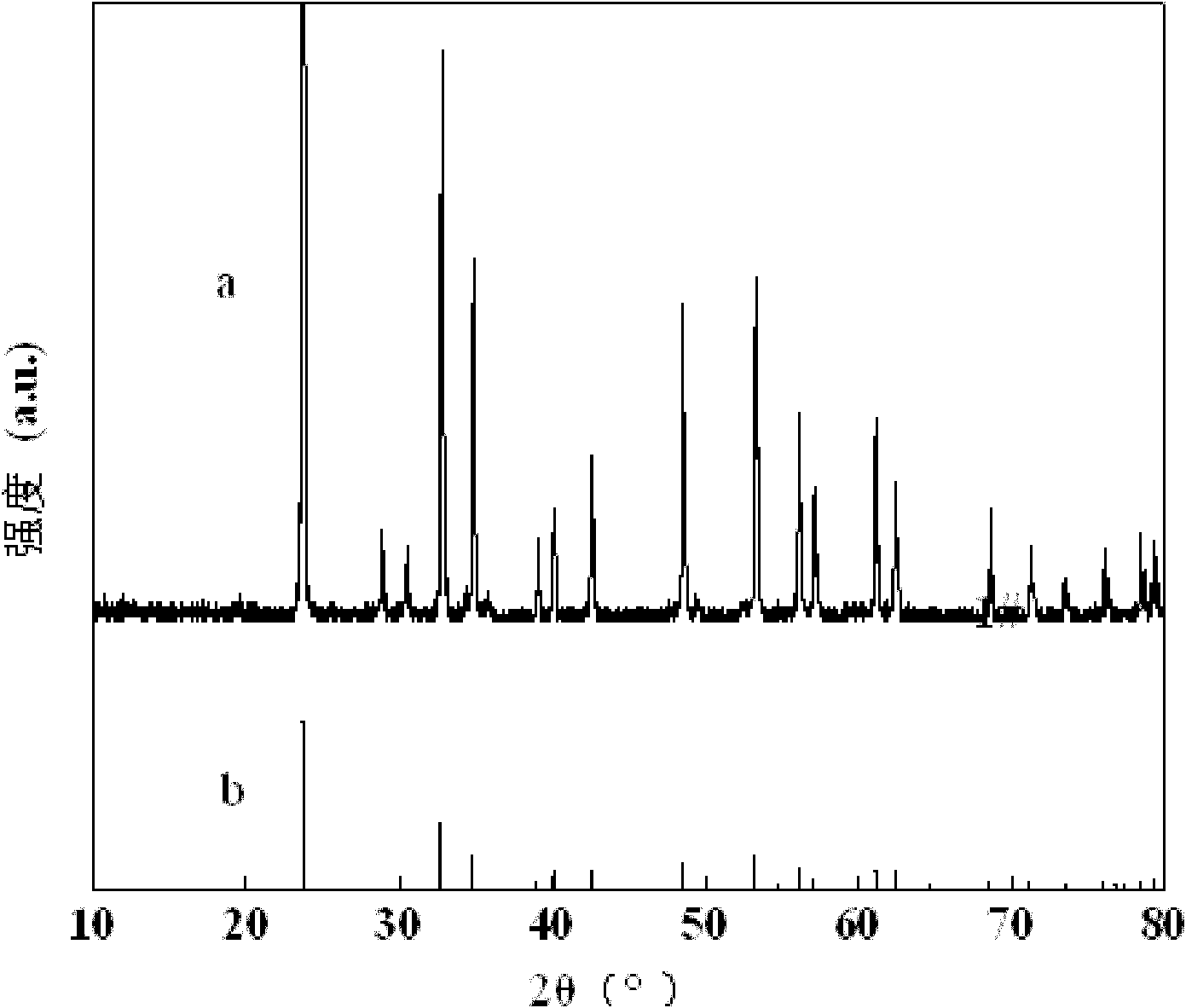

Hydrothermal synthesis method for sodium niobate powder

The invention discloses a hydrothermal synthesis method for sodium niobate powder, which comprises the following steps: putting niobium pentaoxide and sodium hydroxide in a molar ratio of 0.05-10 into an autoclave, and adding deionized water into the autoclave according to a filling rate between 50 and 90 percent to adjust the concentration of the sodium hydroxide to between 0.1 and 15 mol / L; sealing the autoclave, putting the autoclave into a pit furnace or an oven, raising the temperature to between 120 and 240 DEG C in a temperature rise rate of 1 to 5 DEG C per minute, preserving heat for 4 to 72 hours, and then cooling along with the furnace; and taking out and opening the autoclave, pouring an obtained product into a beaker, repeatedly filtering and washing with deionized water until the washed solution is neutral, putting obtained powder into an oven, and baking at a temperature of between 40 and 100 DEG C for 6 to 24 hours. The method is simple, saves energy, reduces emission, has low cost, and is suitable for mass production; and the prepared sodium niobate powder has high purity, good fluidity, narrow particle size distribution, low degree of particle agglomeration, and perfect crystal growth.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

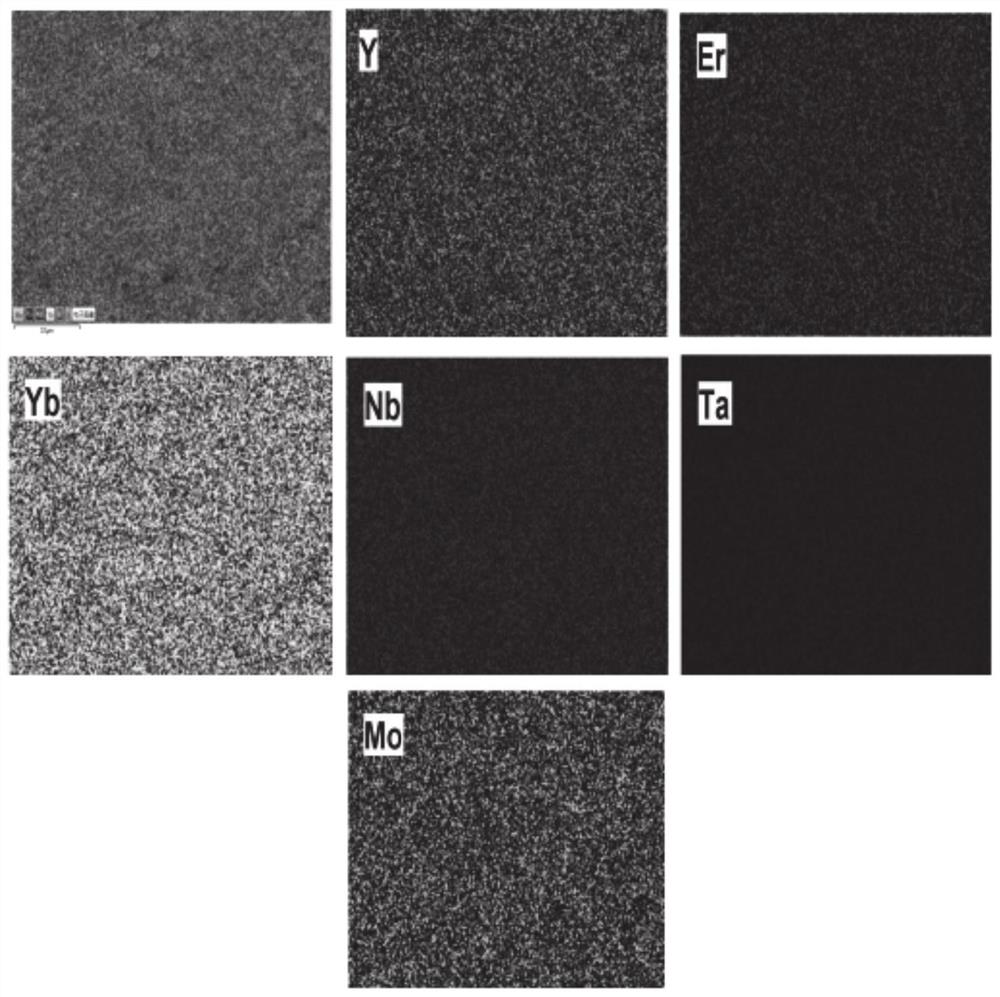

High-entropy rare earth niobium/tantalum/molybdate ceramic and preparation method thereof

The invention relates to the technical field of high-entropy ceramic materials, and particularly provides high-entropy rare earth niobium / tantalum / molybdate ceramic and a preparation method thereof. The chemical formula of the high-entropy rare earth niobium / tantalum / molybdate ceramic is RE3(Nb1 / 3Ta1 / 3Mo1 / 3)O7, RE is any 3-7 different elements of Y, Nd, Sm, Eu, Gd, Dy, Ho, Er, Yb and Lu. The preparation method comprises the following steps of (1) weighing rare earth oxide, niobium pentoxide, tantalum pentoxide, molybdenum trioxide and molybdenum dioxide according to a stoichiometric ratio, (2) adding a solvent and a ball-milling medium, ball-milling and mixing the raw materials by adopting a wet method, and carrying out vacuum drying and sieving to obtain uniformly mixed powder, (3) placing the uniformly mixed powder in a stainless steel mold for hydraulic compaction, and then carrying out cold isostatic pressing to obtain a densified green body, and (4) putting the green body into an alumina crucible, putting the alumina crucible into a high-temperature sintering furnace, and sintering in an air atmosphere. The prepared high-entropy ceramic is low in heat conductivity, the adopted preparation method has the advantages of being simple and rapid in process, low in equipment requirement, low in energy consumption, high in controllability and the like, and large-scale production is easy to achieve.

Owner:SHANDONG UNIV

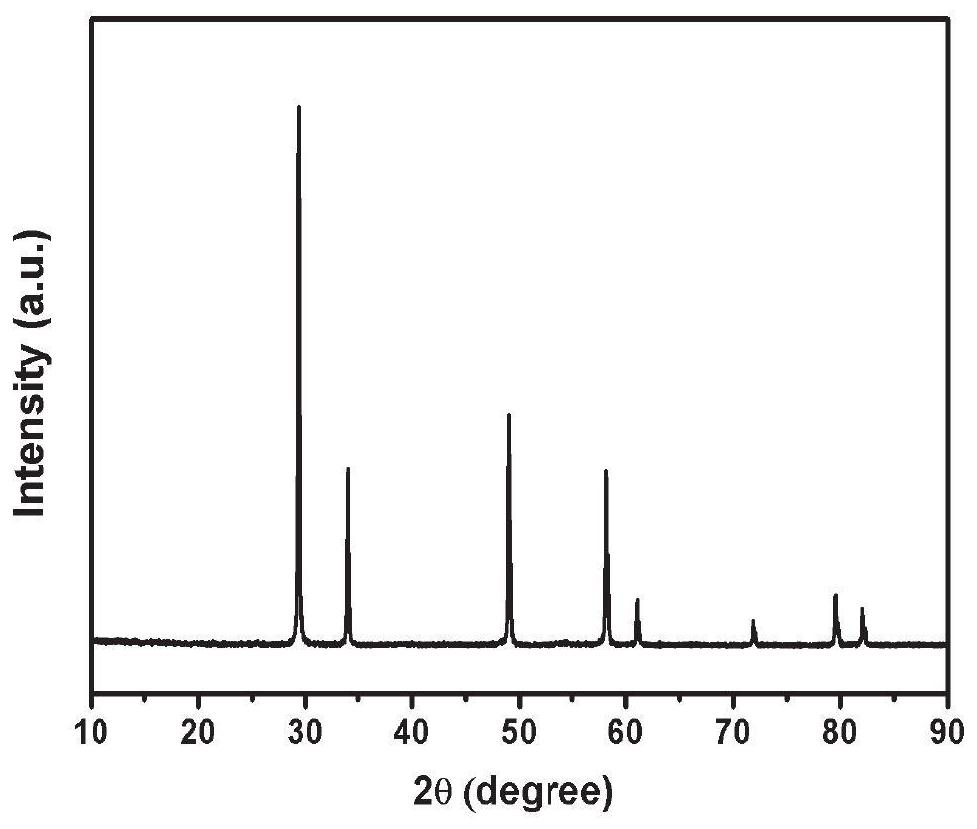

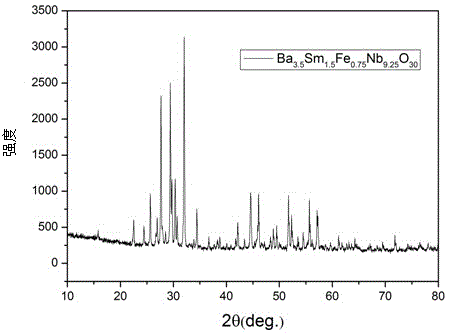

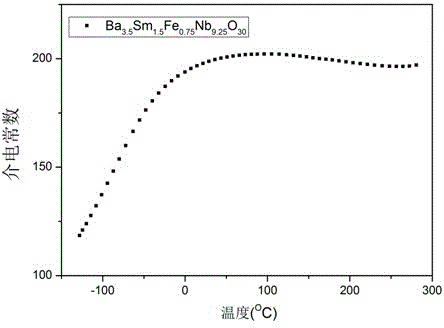

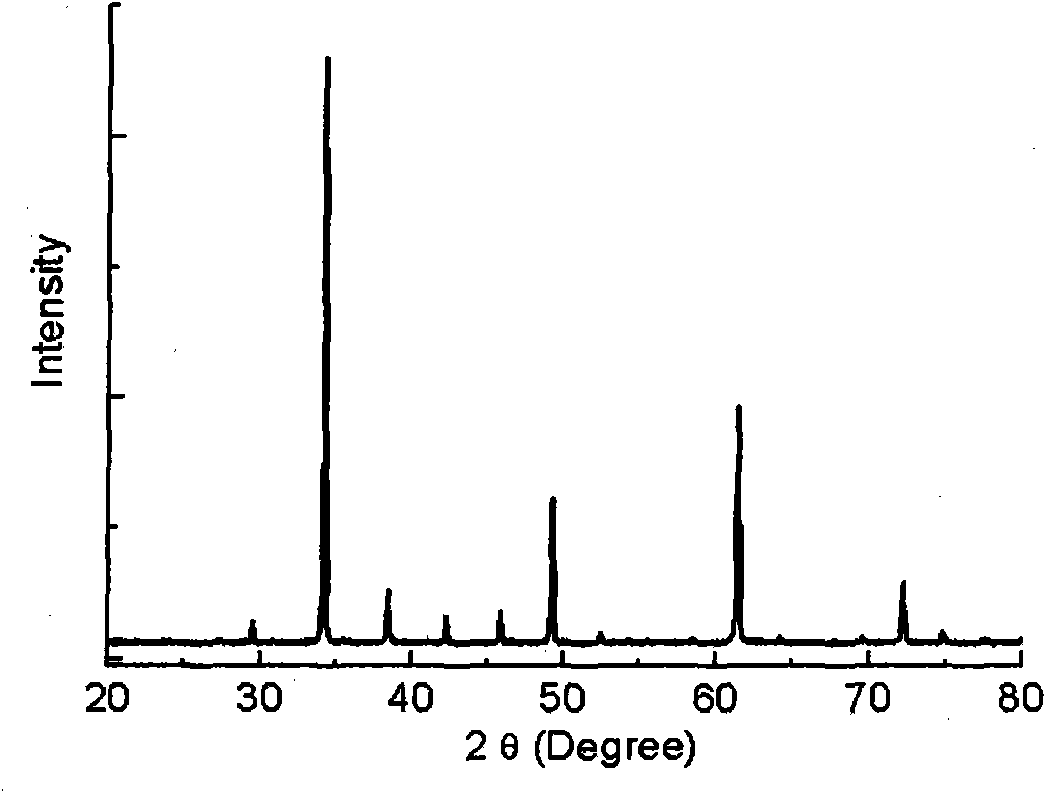

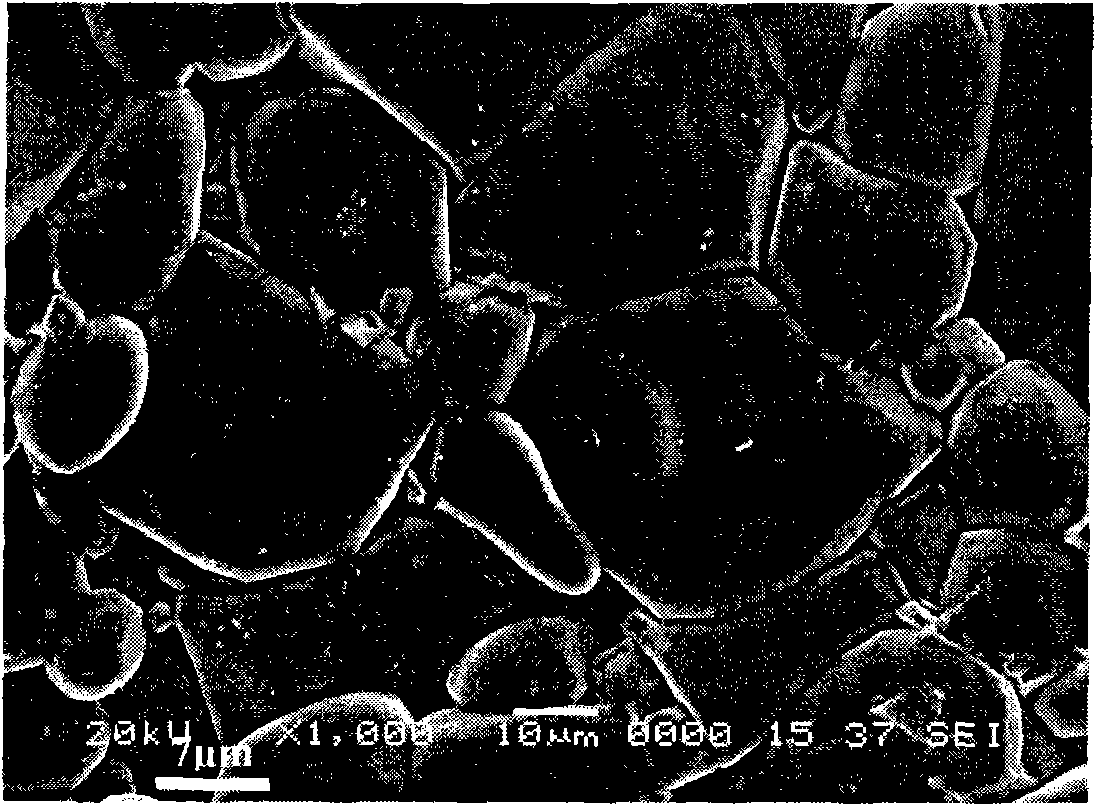

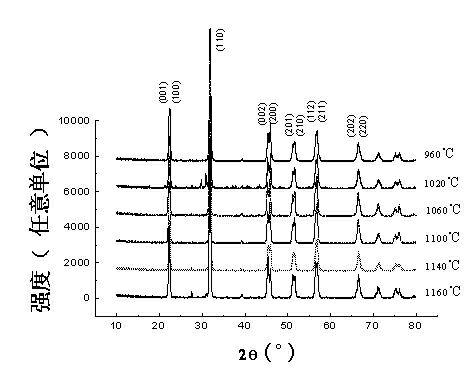

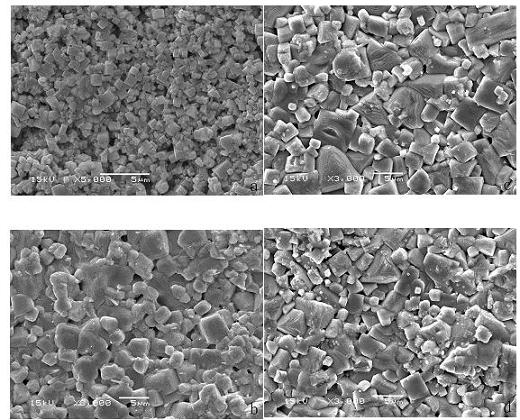

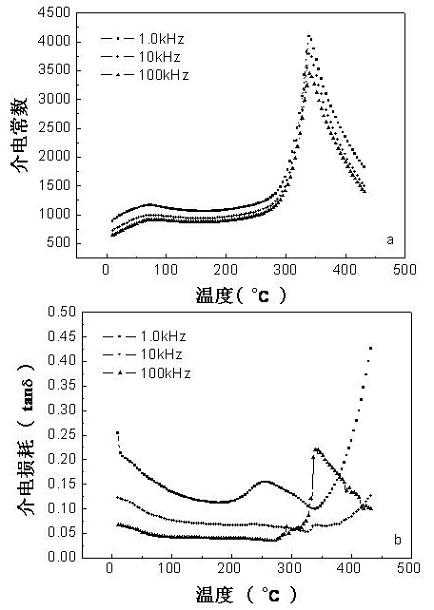

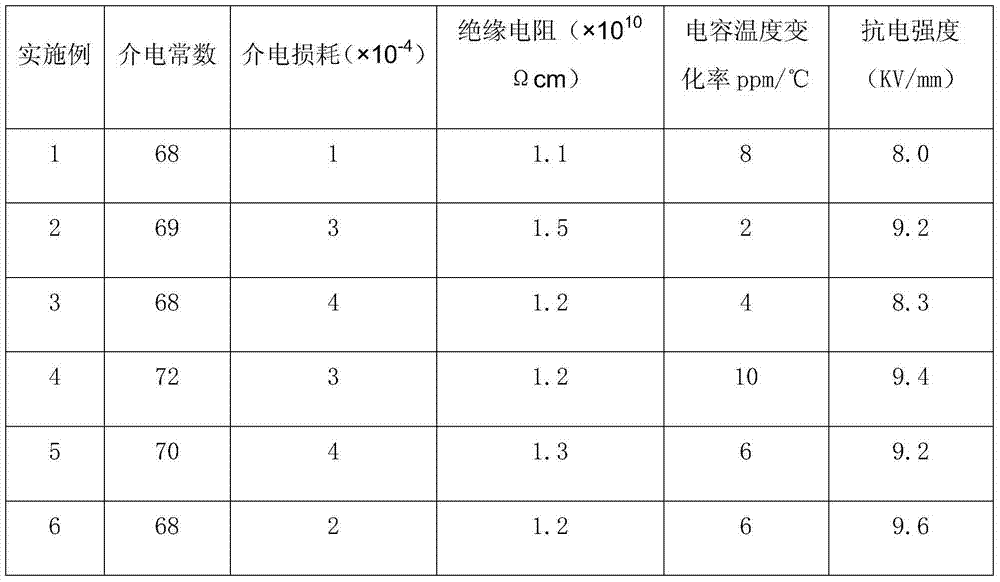

X9R ceramic capacitor dielectric material and preparation method thereof

The invention discloses an X9R ceramic capacitor dielectric material and a preparation method thereof. The preparation method comprises the following steps: niobium pentoxide, barium carbonate, ferric oxide and samarium oxide are subjected to ball milling firstly, raw materials are refined, burdening is performed at stoichiometric ratio according to the nominal chemical formula Ba3.5Sm1.5Fe0.75Nb9.25O30, procedures including presintering, second ball milling and the like are performed, and the X9R ceramic capacitor dielectric material Ba3.5Sm1.5Fe0.75Nb9.25O30 is finally prepared through a solid-phase reaction and a decarbonation process. The ceramic capacitor dielectric material with good temperature stability can be obtained with the method, the EIA (Electronic Industries Association) X9R standard can be met; and the method is simple and suitable for batch production, the cost is moderate, and energy conservation and emission reduction are realized.

Owner:苏州弘吴科技中介服务有限公司

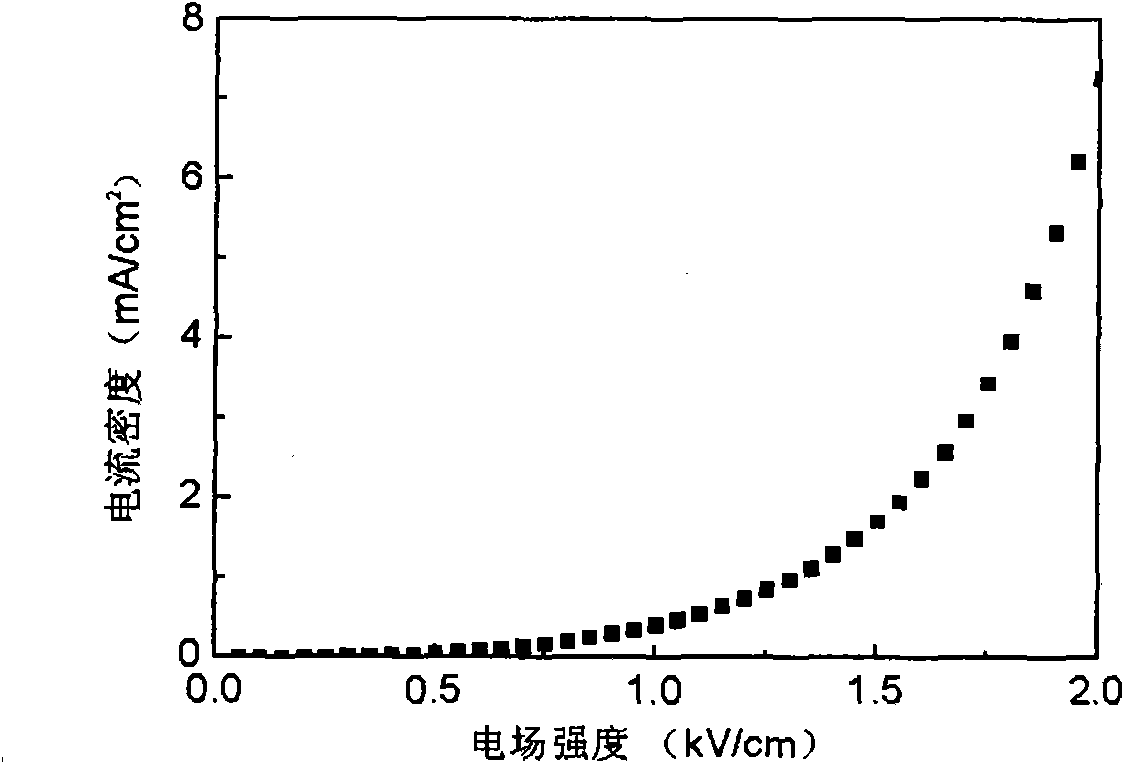

Group VB doping CaCu3Ti4O12 based pressure sensitive material and preparation method

InactiveCN101880159AIncrease intrinsic conductanceReduce the voltage gradientLow voltageChemical element

The invention discloses a group VB doping CaCu3Ti4O12 based pressure sensitive material and a preparation method. The general chemical composition formula of the group VB doping CaCu3Ti4O12 based pressure sensitive materia is CaCu3Ti4-xBxO12, wherein B represents one or combination of group VB elements in the periodic table of chemical elements, and x=0.001-1. The preparation method comprises thefollowing steps of compounding calcium carbonate, copper oxide, vanadium pentoxide, niobium pentaoxide and tantalum pentoxide in accordance with the stoichiometric ratio of CaCu3Ti4-xBxO12 (x=0.001-1, and B represents one or combination of group VB elements in the periodic table of chemical elements), ball milling, calcining, secondary ball milling, pelleting, forming, binder removing, high temperature sintering and the like so that Ca, Cu, Ti-O based ceramics with high permittivity and high pressure sensitive feature can be finally prepared. The invention compensates valence changes of copper ions and titanium ions in the sintering process, which can cause low voltage gradient and large leakage current, by partially replacing a +4 Ti element with a +5 element, thereby reducing the intrinsic conductivity of materials and improving the voltage gradient of the materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

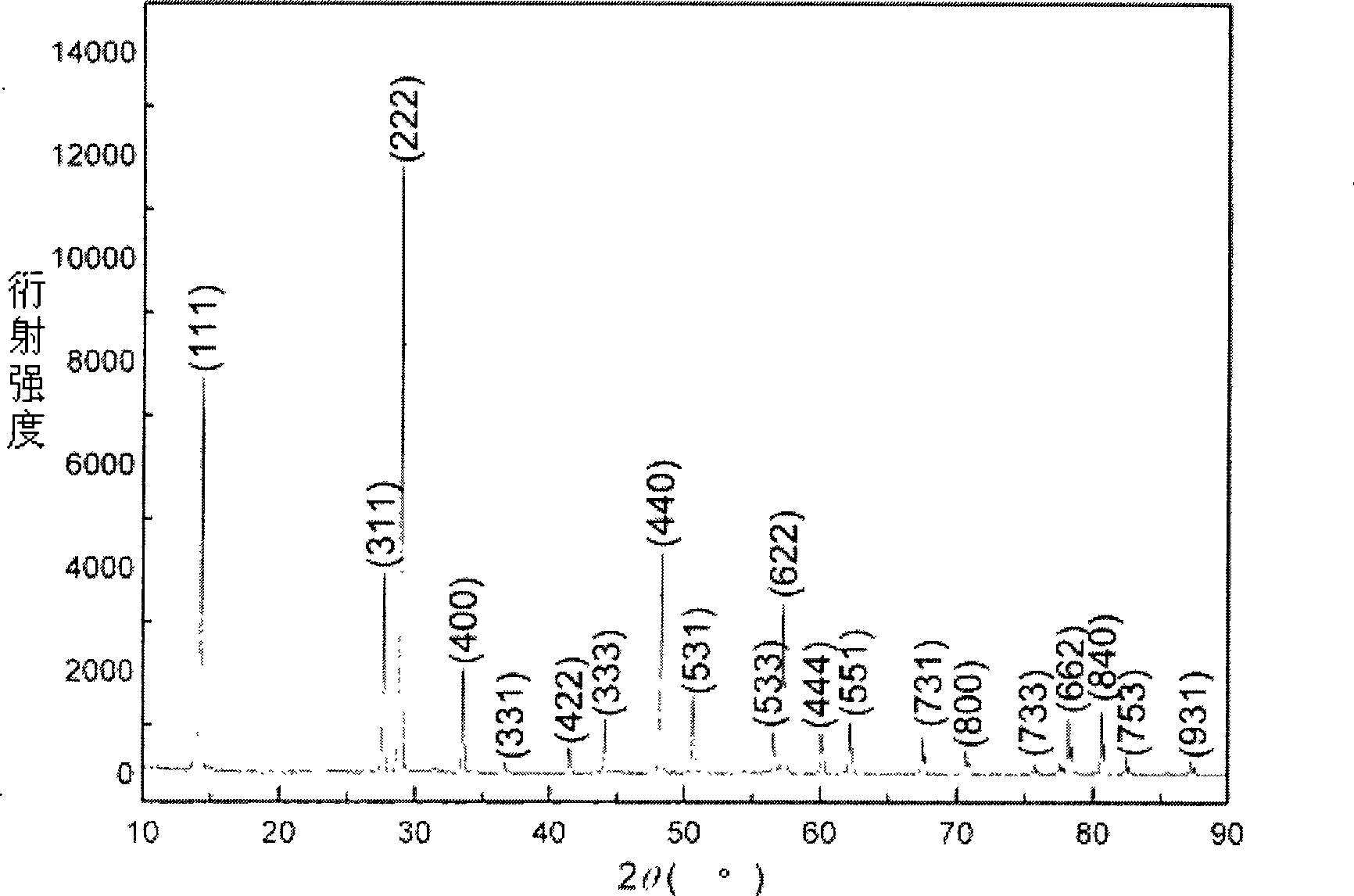

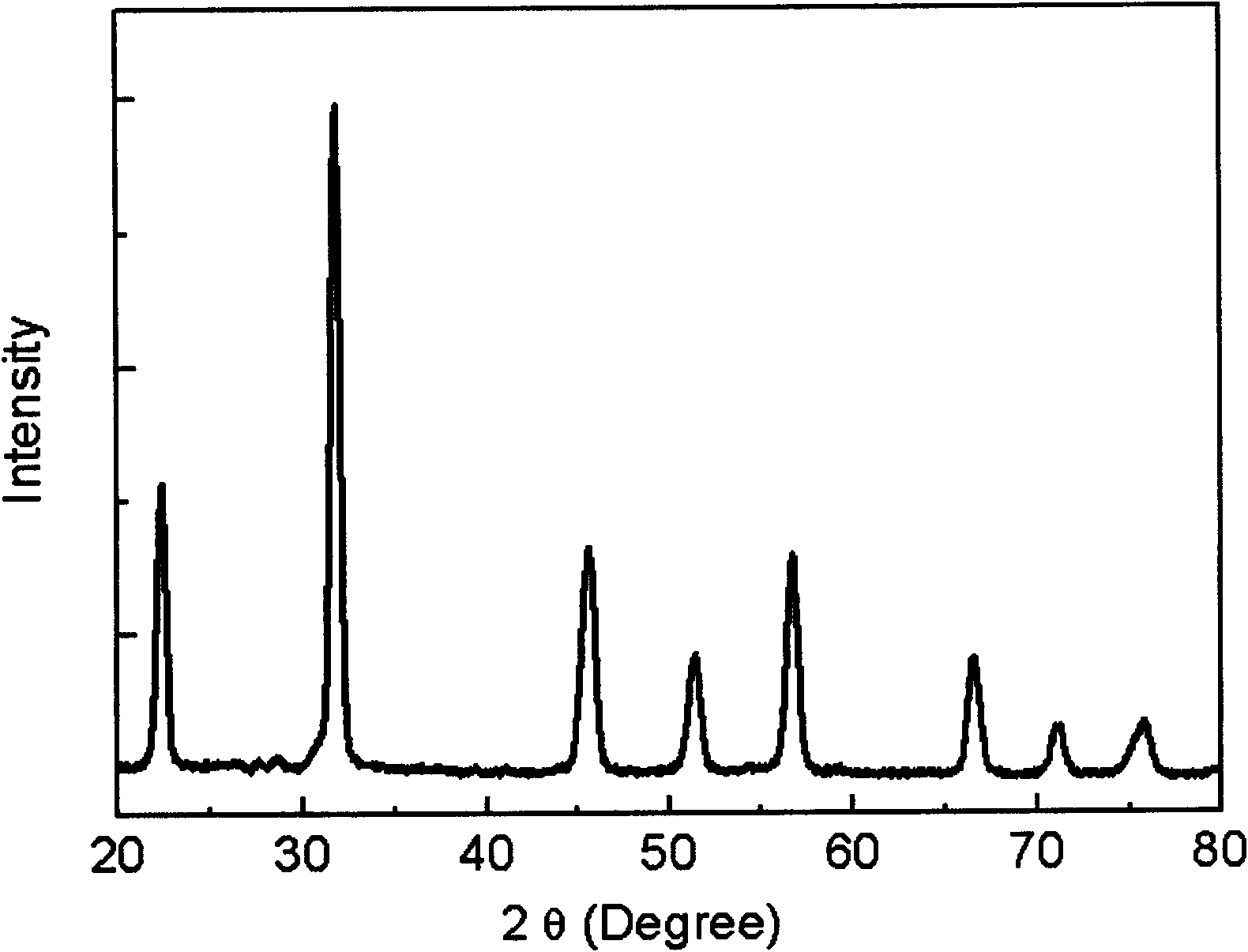

Method for preparing niobate photocatalyst

InactiveCN101433834AHigh crystallinityNarrow particle size distributionMetal/metal-oxides/metal-hydroxide catalystsPotassium hydroxidePhotodegradation

The invention discloses a method for preparing a niobate photocatalyst, and relates to a method for preparing a photocatalyst. The method solves the problems that a photocatalyst prepared by the prior method has poor adsorptivity and low photodegradation efficiency. The preparation method comprises the following steps: 1. niobium pentaoxide and potassium hydroxide are weighed, and a mixture is prepared through magnetic stirring; 2. the mixture is placed into a high-pressure reaction kettle to be prepared into a precursor of the niobate photocatalyst; and 3. the precursor of the niobate photocatalyst is filtered, washed and dried. The invention is to adopt a method of synthesis by a hydro-thermal method to realize the synthesis of the niobate photocatalyst first. The obtained product has high purity, good absorption performance, and high photodegradation efficiency; and the method has cheap raw materials, simple process and simple equipment.

Owner:HARBIN INST OF TECH

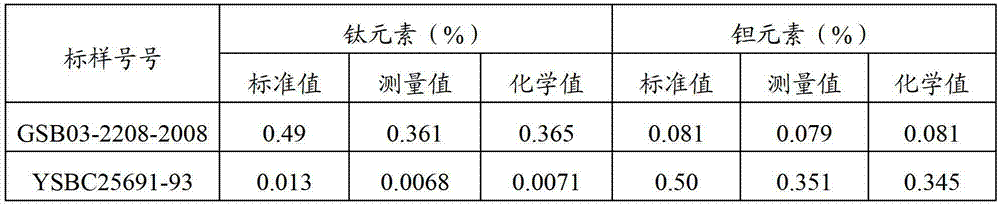

Method for testing niobium content in niobium-iron alloy

InactiveCN103115916AAccurate measurementAccurate calculationPreparing sample for investigationAnalysis by thermal excitationTitaniumUltimate tensile strength

The invention discloses a method for testing niobium content in a niobium-iron alloy. The method comprises the steps of dissolving a niobium-iron alloy sample, depositing the niobium in the niobium-iron alloy in a niobium pentaoxide sediment mode, and weighing the mass of the niobium pentaoxide; preparing a niobium pentaoxide sediment solution, and preparing a standard solution, wherein the standard solution comprises a titanium standard solution and a tantalum standard solution; introducing the solution into which the niobium pentaoxide sediment is dissolved into an inductively coupled plasma atom emission spectrometer so as to test the spectral line intensity of the titanium and the tantalum, and obtaining the content of the titanium and the tantalum in the niobium pentaoxide sediment according to the spectral line intensity which is tested from the standard solution with known concentration; and subtracting the content of the titanium and the tantalum from the content of the niobium pentaoxide so as to obtain the content of the niobium in the niobium-iron alloy. By utilizing the technical scheme of the invention, the content of the titanium and the tantalum which are deposited together with the niobium in the niobium-iron alloy can be rapidly and accurately tested, thereby accomplishing the precise calculation on the niobium in the niobium-iron alloy.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

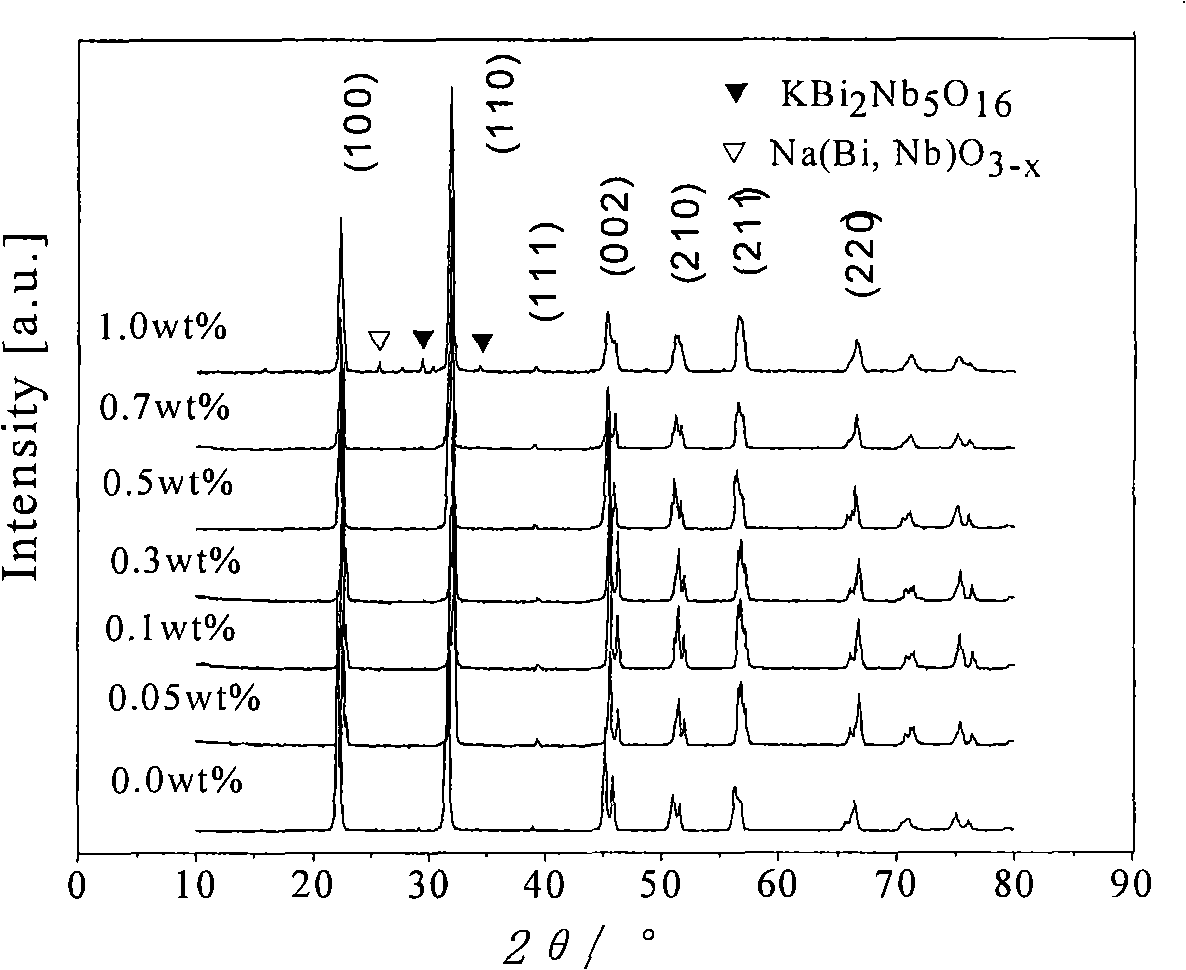

Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

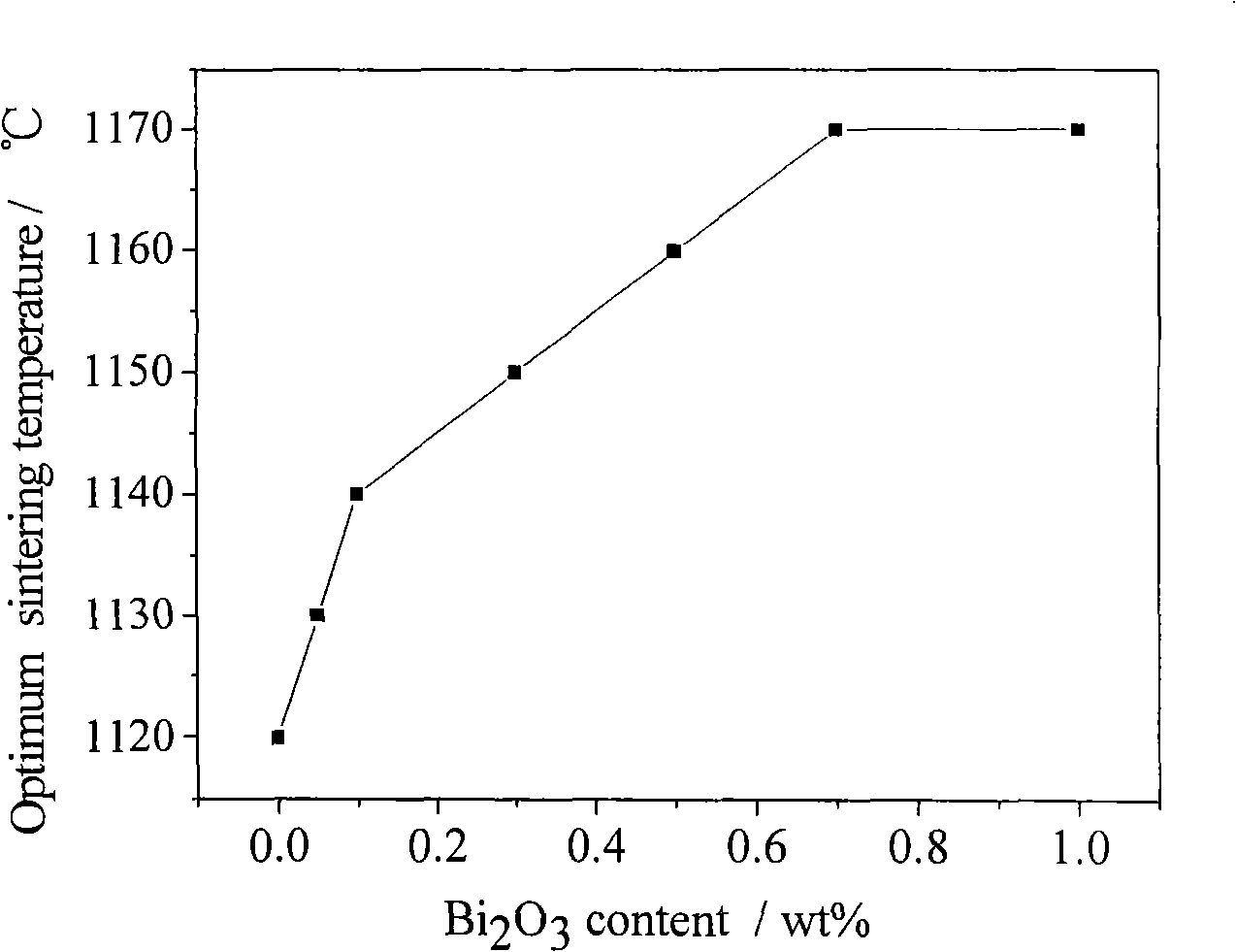

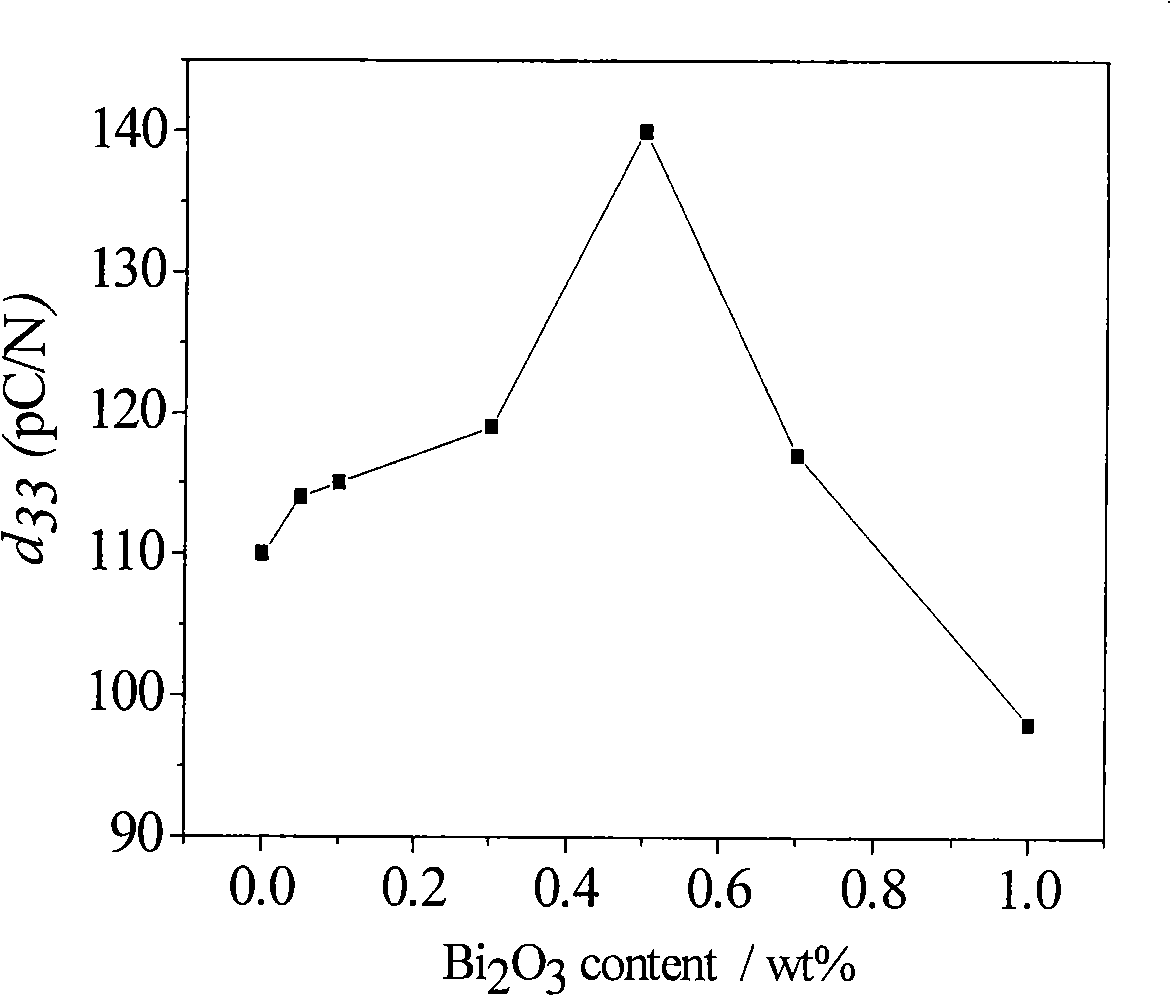

InactiveCN101302106AImprove sintering propertiesHigh degree of densificationSilver electrodeDrain current

The invention discloses a piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate and a preparing method, which strengthens the ferroelectric performance of potassium-sodium niobate ceramic and further improves the piezoelectric performance. The material of the invention comprises anhydrous potassium carbonate, natrium carbonicum calcinatum, niobium pentaoxide and dibismuth trioxide, the stoichiometric proportion of the lead-free piezoelectric ceramic is (K0.5 Na0.5) Nb3 + x weight percent Bi 2O3, wherein the x is more than or equal to 0 and less than or equal to 1, the piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate is obtained through mixture making, drying and burnishing, granulation, molding, sintering and after polarization by a silver electrode; therefore, the densification of the ceramic is improved, polarized drain current of the ceramic is reduced, and the polarization process is carried out more easily; moreover, the piezoelectric material adopts the material from a conventional process and industry, has the characteristics of good process stability and no pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

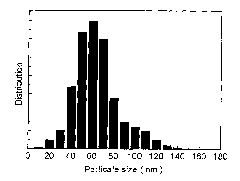

Nano functional ceramic material and preparation method thereof

The invention provides a nano functional ceramic material, and in particular relates to a nano functional ceramic material with an ABO3 perovskite structure and a method for preparing the material. The method comprises the following steps: preparing an organic solvent solution of alkali metal hydroxide; adding the weighed organic solvent solution in a polytetrafluoroethylene lining of a reaction kettle, and stirring; adding weighed niobium pentaoxide powder and tantalum pentoxide powder in the polytetrafluoroethylene lining according to the chemical dose proportion of a ceramic material molecular formula and the concentration and volume of an organic solvent, and then continuing to stir; putting the polytetrafluoroethylene lining in a stainless steel hydro-thermal reaction kettle for a solvent heat reaction so as to obtain a precipitate; and processing the obtained precipitate so as to obtain A(NbxTa1-x)O3 nano powder. In the method, the characteristics of the organic solvent are fully utilized, the ceramic powder is synthesized under the milder conditions; the powder has the advantages of good dispersibility and uniformly distributed crystallite dimension; the steps are simple and easy to operate and achieve; and the synthesis conditions are mild, thus being convenient for industrial production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Normal-pressure densification method of sodium potassium niobate-based leadless piezoelectric ceramic

The invention discloses a normal-pressure densification method of sodium potassium niobate-based leadless piezoelectric ceramic, and belongs to the technical field of the preparation of functional ceramic materials. Sodium carbonate, potassium carbonate and niobium pentaoxide are taken as main raw materials; the leadless piezoelectric ceramic with high density is prepared by sintering the raw materials under normal pressure by the conventional solid reaction method by adding second components such as calcium titanate, lithium antimonate, lithium tantalate and the like without sintering processes such as vacuumization, hot pressing / hot isostatic pressing and the like; and the prepared ceramic which consists of a morphotropic phase boundary has high piezoelectric and ferroelectric properties. By the method, the defects of over-high equipment requirements, rigorous production processes and higher production cost of the sintering processes such as the hot pressing and the like are overcome; and the leadless piezoelectric ceramic with the high density and high piezoelectricity is prepared by a normal pressure sintering process by adding the second components and optimizing process parameters.

Owner:CHANGZHOU UNIV

Super-stable temperature type electronic ceramic material

The invention discloses a super-stable temperature type electronic ceramic material and a preparation method thereof and belongs to the technical field of dielectric ceramics. The super-stable temperature type electronic ceramic material mainly comprises the following raw materials in parts by weight: 25-38 parts of barium titanate, 8-10 parts of aluminum oxide, 15-25 parts of zirconium dioxide, 10-20 parts of manganese oxide, 3-9 parts of nickel oxide, 2-8 parts of zinc oxide, 0.01-0.1 part of gallium oxide, 10-18 parts of nano silicon dioxide, 1-5 parts of magnesium oxide, 2-8 parts of nano boron nitride and 0.1-1.5 parts of thulium oxide. According to the ceramic material disclosed by the invention, the rare earth thulium oxide is used for replacing frequently-used cerium oxide and niobium pentaoxide components, and the ceramic material has obvious effects of further promoting fine crystallization of a ceramic body, improving the pressure resistance and reducing the losses. The ceramic material disclosed by the invention is simple in formula and low in price.

Owner:蔡惠文

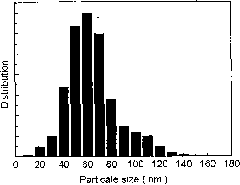

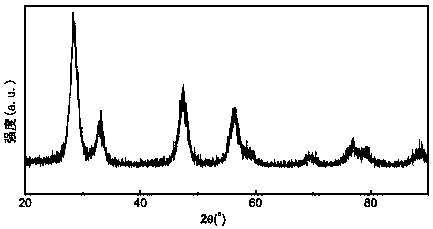

Preparation method of spherical nanoscale niobium pentaoxide powder

The invention relates to a preparation method of spherical nanoscale niobium pentaoxide powder, comprising the following steps: niobium hydroxide and oxalic acid are heated and boiled in distilled water to prepare niobium oxalate solution; carbon black, the niobium oxalate solution and ethanediol are mixed according to proportion, the mass ratio of the niobium pentaoxide and the carbon black is 1:2-1:9, and the volume ratio of the niobium oxalate solution and the ethanediol is 1:2-1:3; pH value is adjusted to be 8-9 by ammonia water; the mixture is stirred, and the temperature is kept to be 60-70 DEG C for 8-15 minutes, and then cooling, water filling, placing still, filtering and drying are carried out; the dries product is calcined in a muffle furnace, so as to obtain the spherical nanoscale niobium pentaoxide powder. The prepared spherical nanoscale niobium pentaoxide powder has small grain diameter, particles are uniform and spherical and the dispersity is good; the purity of the product can reach more than 99.99 percent; the whole technological process is simple, the raw material source is wide, the price is low, the process is safe, and the method is beneficial to realizing industrialization.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Preparation method of potassium-sodium niobate-potassium-bismuth titanate nano ceramics

The invention discloses a preparation method of potassium-sodium niobate-potassium-bismuth titanate nano ceramics. The potassium-sodium niobate-potassium-bismuth titanate contains niobium pentaoxide, sodium carbonate, potassium carbonate, titanium dioxide and dibismuth trioxide with the stoichiometric ratio of (1-x)[(Na0.5K0.5)NbO3]-x[(Bi0.5K0.5)TiO3], wherein x is more than 0.1 but less than 0.9; the potassium-sodium niobate-potassium-bismuth titanate nano ceramics is prepared by the procedures of material blending, high-energy ball milling of the mixed material, pre-sintering, cold isostatic pressing formation, high-temperature sintering, grinding and polishing and sputtering of gold electrode. According to the invention, since the grain size of the ceramics is effectively varied owing to the different ingredient proportions adopted, a series of electronic ceramics from micron level to nanometer level is prepared and further, the electronic ceramics with different piezoelectricity and dielectricity is prepared. The preparation method adopting the method of high-energy ball milling and appropriate chemical proportions achieves great simplicity, proper cost and excellent suitability for batch production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

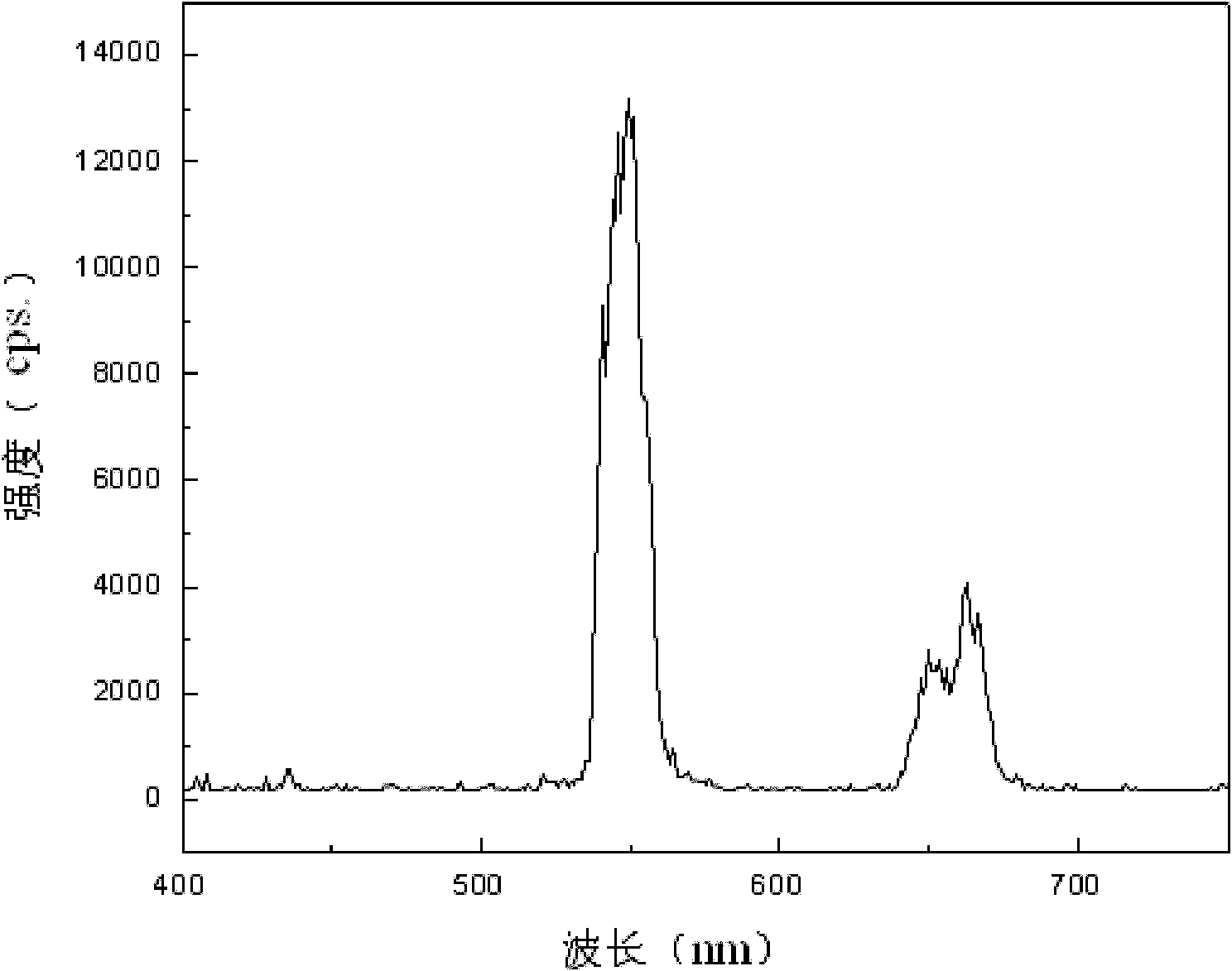

Ytterbium and holmium codoped lithium niobate crystals and preparation method thereof

InactiveCN102127814AImprove up-conversion luminous efficiencyGood resonance absorptionPolycrystalline material growthBy pulling from meltYTTERBIUM OXIDEHolmium

The invention discloses ytterbium and holmium codoped lithium niobate crystals and a preparation method thereof, and relates to doped lithium niobate crystals and a preparation method thereof, which solve the technical problems that the conventional lithium niobate crystals cannot be used as a laser crystal material. The ytterbium and holmium codoped lithium niobate crystals are prepared from niobium pentaoxide, lithium carbonate, ytterbium oxide and holmium oxide. The method comprises the following steps of: mixing the niobium pentaoxide, the lithium carbonate, the ytterbium oxide and the holmium oxide and baking to obtain polycrystal powder; growing crystals at equal diameter from the polycrystal powder in a single crystal growth furnace through seeding, necking, shouldering and folding by a crystal pulling method; and annealing to obtain the ytterbium and holmium codoped lithium niobate crystals. The ytterbium and holmium codoped lithium niobate crystals can emit red light and green light when activated by laser of 980nm and has a broad application prospect in the fields of optical data storage, submarine communication, optical display, color display, photoelectrons, medical diagnosis and the like.

Owner:HARBIN INST OF TECH

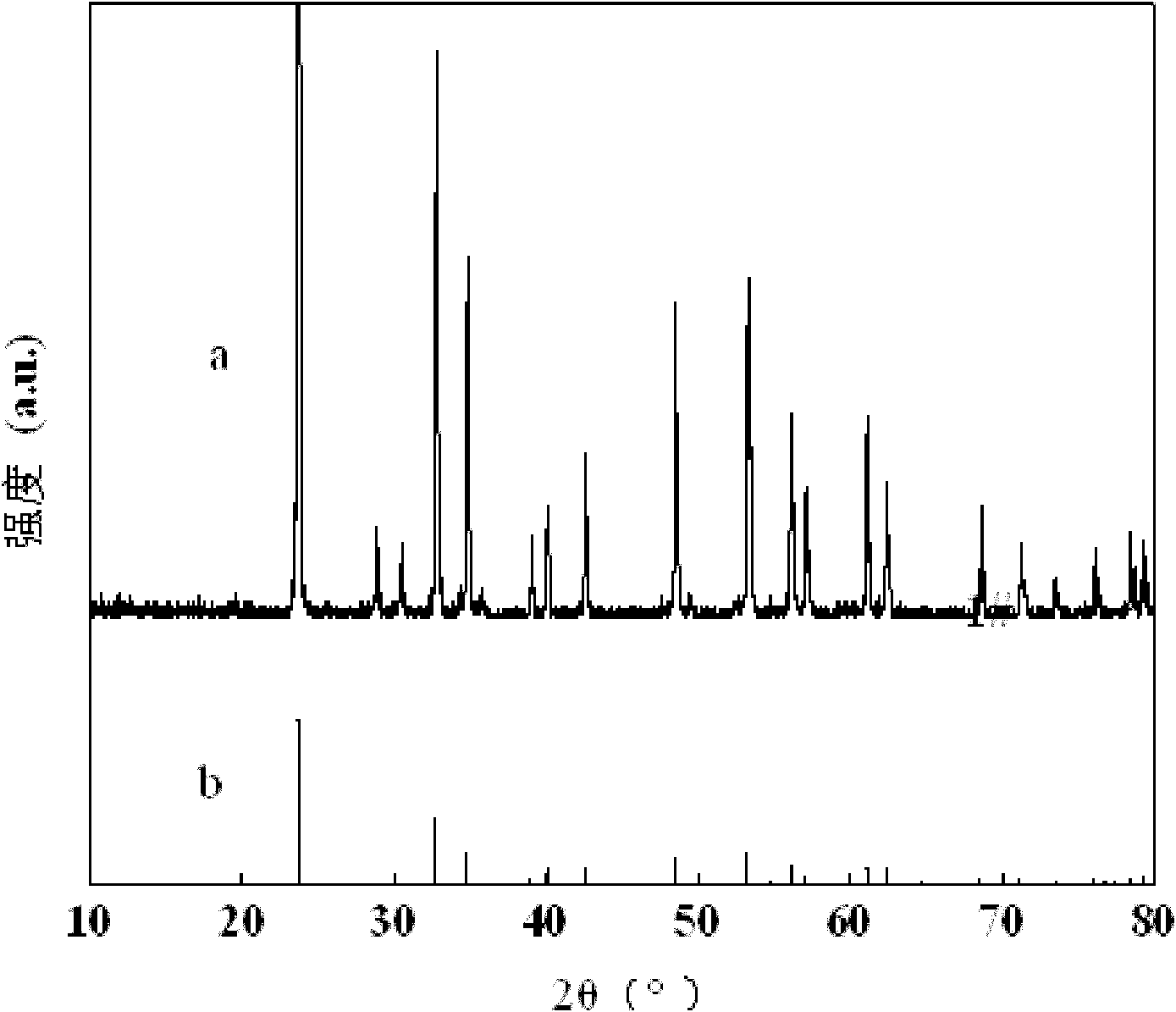

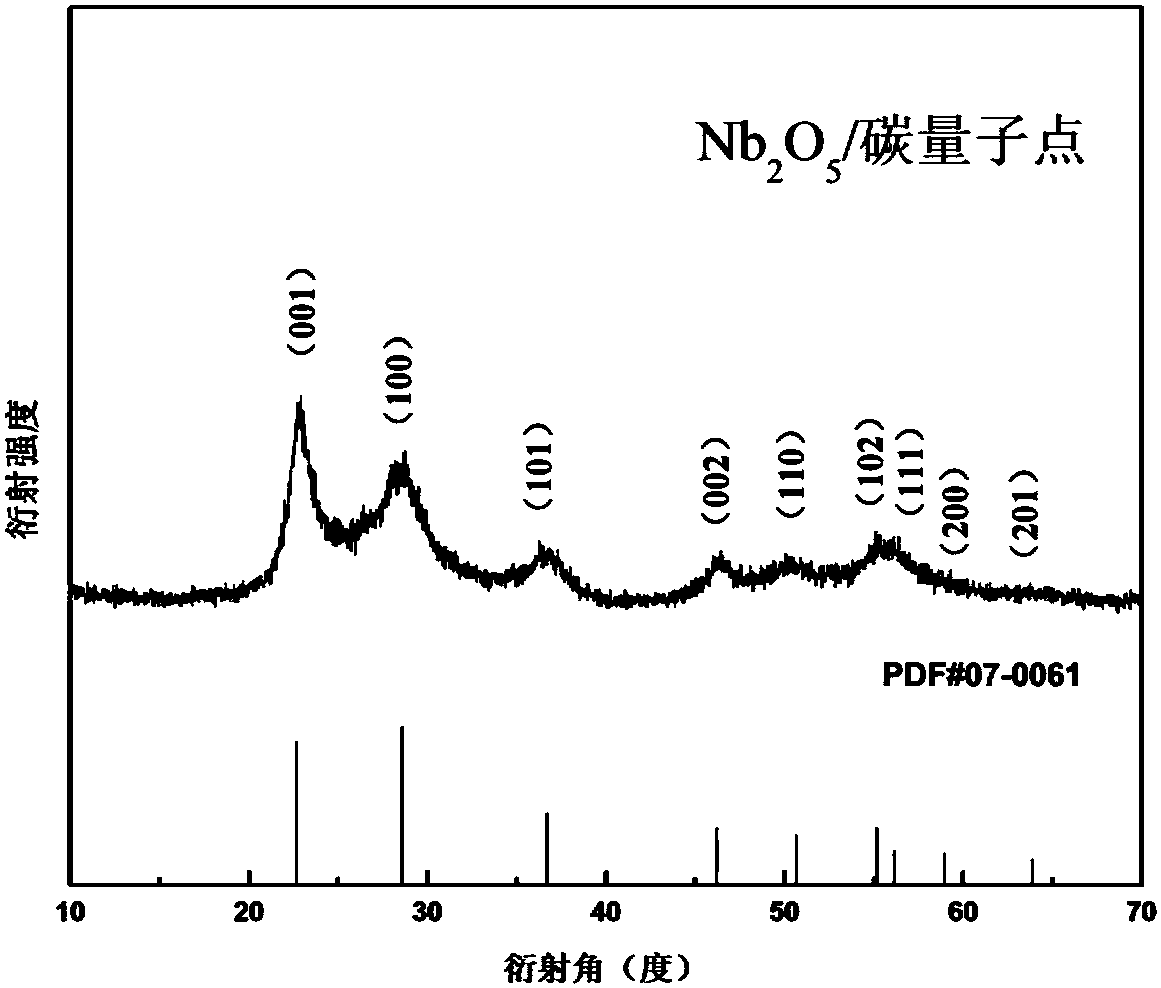

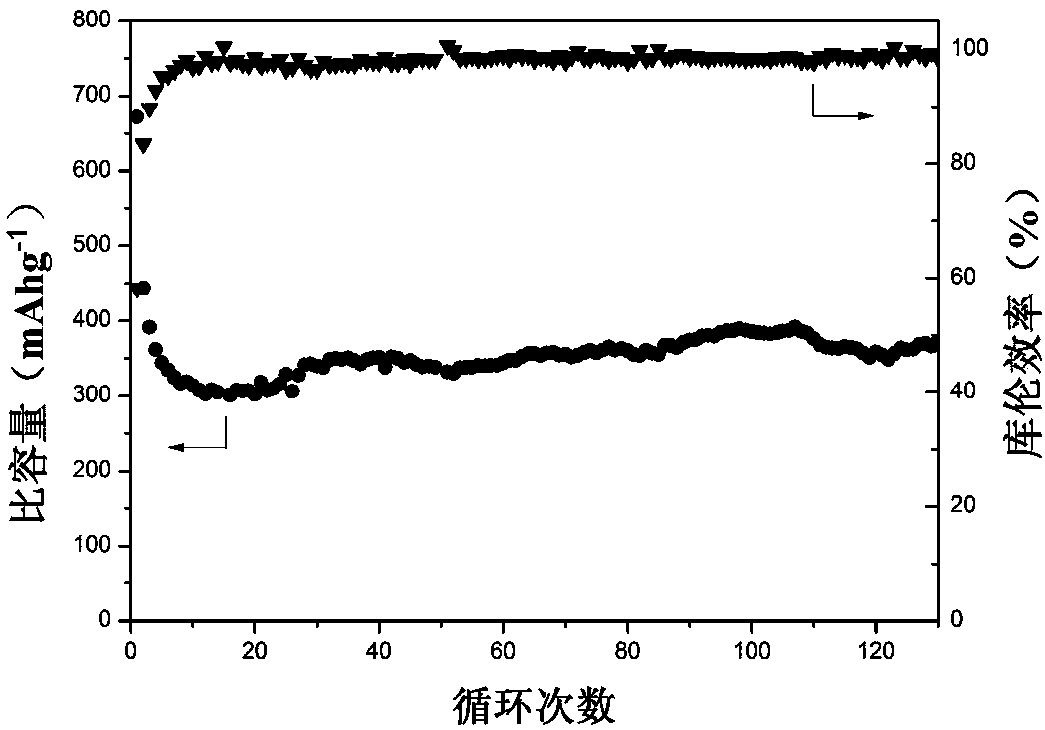

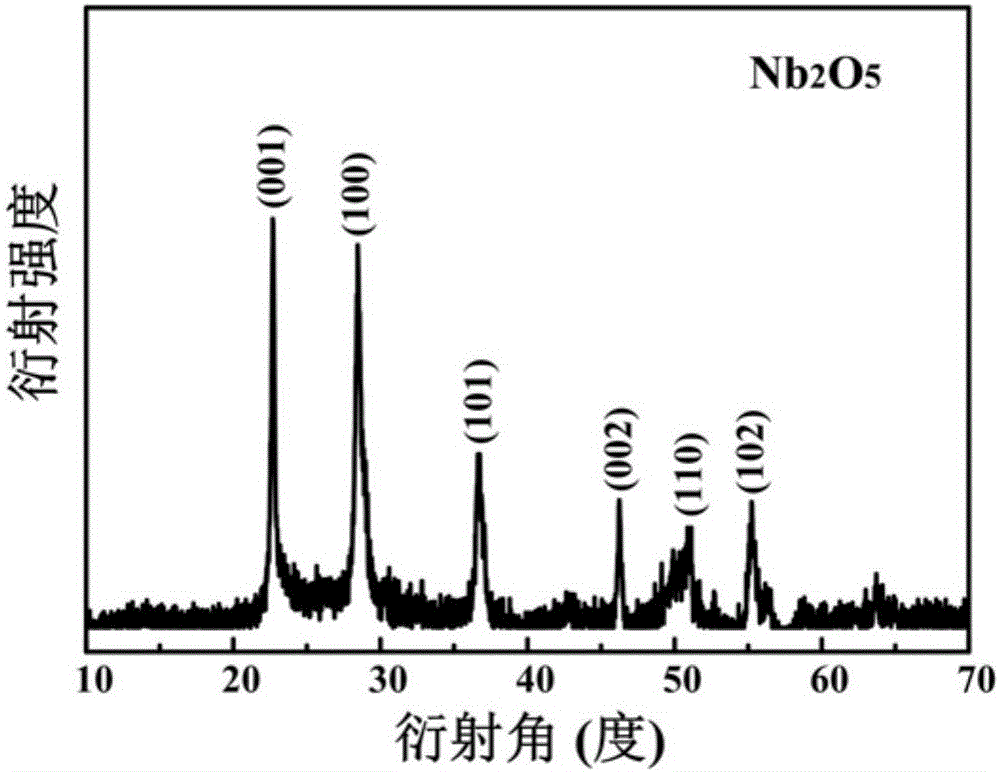

Niobium pentoxide/carbon double-quantum-dot nanometer composite material, method for preparing same and application of niobium pentoxide/carbon double-quantum-dot nanometer composite material

ActiveCN108448104AImprove cycle stabilityAlleviate chalking problemsMaterial nanotechnologySecondary cellsNano compositesArgon atmosphere

The invention discloses a niobium pentoxide / carbon double-quantum-dot nanometer composite material, a method for preparing the same and application of the niobium pentoxide / carbon double-quantum-dot nanometer composite material. The niobium pentoxide / carbon double-quantum-dot nanometer composite material comprises niobium pentoxide and carbon double quantum dot. The niobium pentoxide quantum dot and the carbon double quantum dot are closely bonded with each other; the mass fraction of the carbon quantum dot in the niobium pentoxide / carbon double-quantum-dot nanometer composite material is 20-40%. The niobium pentoxide / carbon double-quantum-dot nanometer composite material, the method and the application have the advantages that gaps are reserved between particles of the niobium pentoxide / carbon double quantum dots, and accordingly the niobium pentoxide / carbon double-quantum-dot nanometer composite material has large specific surface areas; the niobium pentoxide / carbon double-quantum-dot nanometer composite material with the structure is favorable for sufficient contact of electrolyte solution and active substances and further can effectively adapt to volume expansion of materials in charge and discharge procedures, and accordingly the electrochemical performance of the niobium pentoxide / carbon double-quantum-dot nanometer composite material can be greatly improved when the niobium pentoxide / carbon double-quantum-dot nanometer composite material is used as a negative electrode material for lithium ion batteries; precursors of niobium and carbon quantum dots are synthesized by the aid of hydrothermal processes at first and then are calcined in argon atmosphere to obtain the niobium pentoxide / carbon double-quantum-dot nanometer composite material; the method is convenientand easy to operate, reaction conditions can be controlled, and scale-up experiments can be facilitated.

Owner:CENT SOUTH UNIV

Method for preparing potassium-sodium niobate-sodium bismuth titanate nano ceramics

The invention discloses a method for preparing potassium-sodium niobate-sodium bismuth titanate nano ceramics, comprising the following steps: analytically pure niobium pentaoxide, sodium carbonate, potassium carbonate, titanium dioxide and bismuth trioxide are mixed and subjected to the procedures of high-energy ball-milling mixing, presintering, cold isostatic pressing, high temperature sintering, and polishing as well as metallic electrode sputtering to finally prepare the potassium-sodium niobate-sodium bismuth titanate nano ceramics; the stoichiometric proportion of the components is (1-x)[(Na0.5Bi0.5)NbO3]-x[(Bi0.5Na0.5)TiO3], wherein x ranges from 0.005 to 0.9. As sosoloid system of the potassium-sodium niobate-sodium bismuth titanate undergoes high-energy ball milling and pressureless sintering, the nanoscale potassium-sodium niobate-sodium bismuth titanate ceramics are prepared; the grain size of the ceramic is reduced from 1-5mum in the prior art to 88-93 nanometers.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

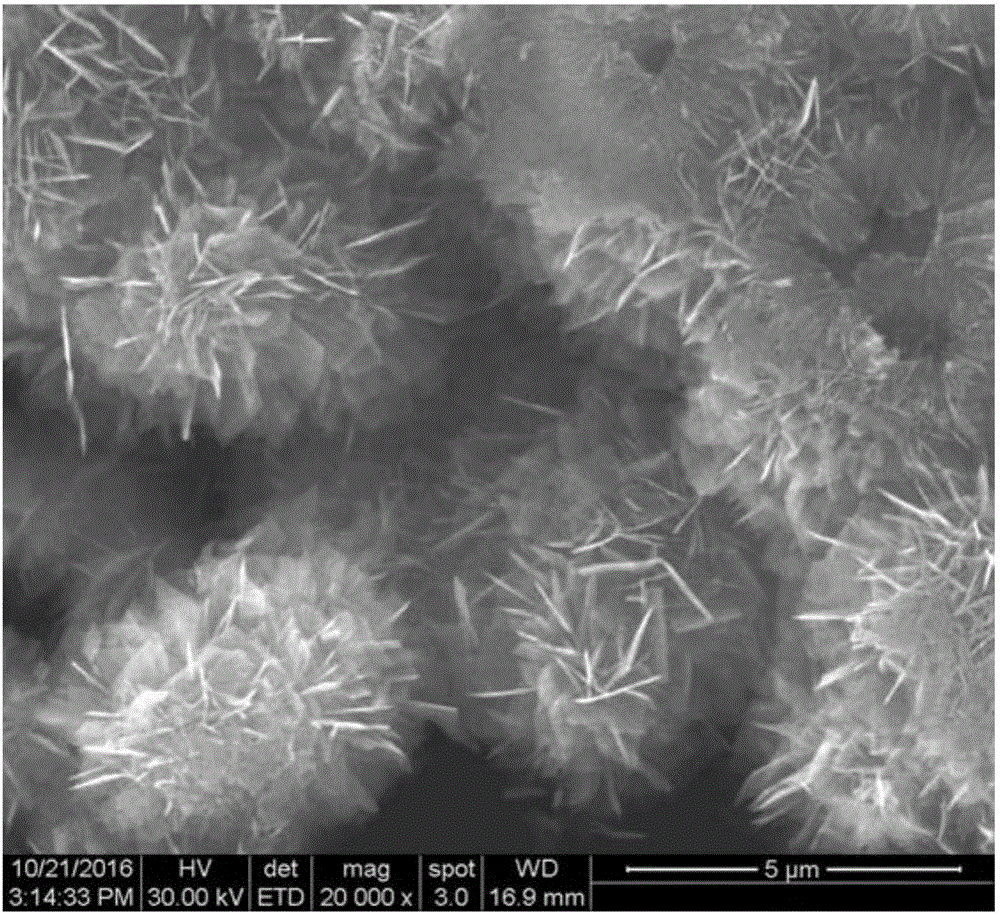

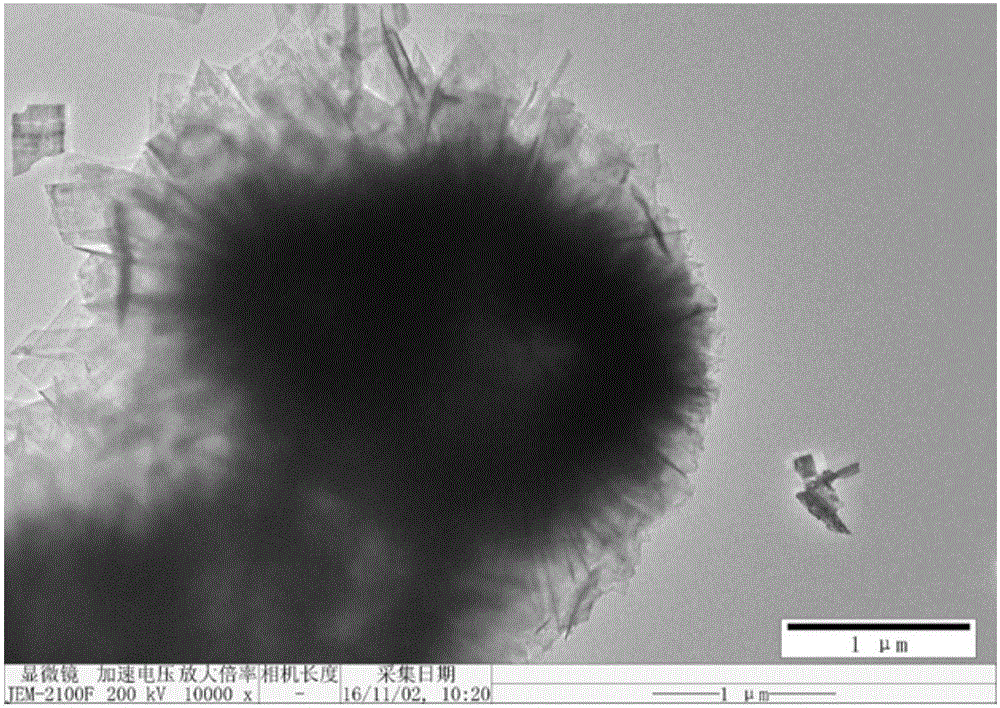

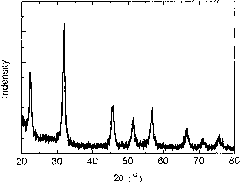

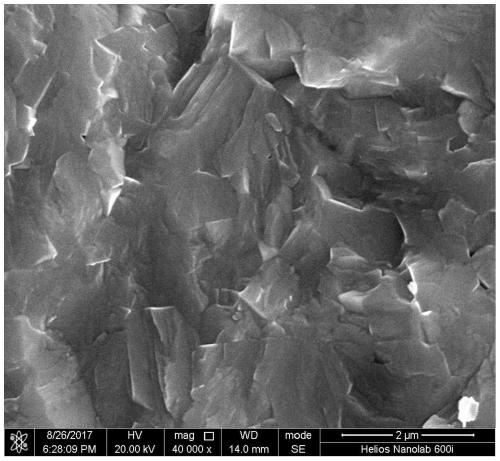

Flower-like niobium pentoxide material and preparation method thereof

InactiveCN106517326AUniform shapeGood dispersionNanotechnologyNiobium compoundsHydrofluoric acidSolar battery

The invention discloses a preparation method of a flower-like niobium pentoxide material. The preparation method comprises the following steps that firstly, columbium pentachloride is dissolved in deionized water; then hydrofluoric acid is added; then the obtained solution is put into a high-pressure reaction kettle for a heating reaction; and finally, cooling is conducted, then washing, drying and roasting are conducted, and the flower-like niobium pentoxide material is obtained. The invention further discloses the flower-like niobium pentoxide material prepared through the method. The prepared flower-like niobium pentoxide material is uniform and regular in morphology and good in dispersibility. The prepared flower-like Nb2O5 is composed of a two-dimensional nanosheet with the thickness of 10 to 30 nanometers, the size of the flower is about 1-3 micrometers, and the flower-like Nb2O5 has the potential application value in the fields of photocatalysis, sensitized solar cells, sensors, energy storage and the like; and according to the preparation method and the flower-like niobium pentoxide material, a synthetic process is simple, the controllability of the reaction condition is high, and the flower-like niobium pentoxide material and the preparation method are suitable for industrial production.

Owner:NANYANG NORMAL UNIV

Solid phase synthetic method of niobate-titanate nano-powder

InactiveCN101798227ASmall granularityLower sintering temperatureSodium bismuth titanatePotassium carbonate

The invention discloses a solid phase synthetic method of niobate-titanate nano-powder. Niobium pentaoxide, sodium carbonate, potassium carbonate, titanium dioxide and bismuth trioxide are in ball milling in advance; raw materials are refined and burdened according to the stoichiometric ratio of (1-x) [(Na0.5K0.5)NbO3]- x[(Bi0.5Na0.5)TiO3], wherein x is more than or equal to 0.00 and is less than or equal to 1.00; and working procedures, such as secondary ball milling for mixing materials, preburning, secondary ball milling and the like, are adopted, solid phase reaction and carbonate decomposable process are utilized to finally prepare potassium-sodium niobate, sodium bismuth titanate or sodium potassium bismuth titanate powder of which the particle size is below 80 nanometers. The method of the invention can prepare a series of niobate-titanate electric ceramics nano-powder, can satisfy requirements of different fields, is simple, has energy saving, emission reduction and moderate cost and is suitable for volume production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High-performance high-entropy (VNbTaMoW)C carbide ceramic and preparation method thereof

The invention belongs to the technical field of high-entropy ceramic, and particularly relates to high-performance high-entropy (VNbTaMoW)C carbide ceramic and a preparation method thereof. The preparation method comprises the steps that vanadium pentoxide micropowder, niobium pentoxide micropowder, tantalum pentoxide micropowder, molybdenum trioxide micropowder, tungsten trioxide micropowder andactivated carbon microspheres are weighed according to designed composition and serve as raw materials; absolute ethyl alcohol is adopted as a medium, ball milling is conducted on the raw materials, and drying is conducted so as to obtain a mixture with uniform components; and hot-press sintering is conducted on the mixture to prepare the high-entropy carbide ceramic. According to the preparationmethod, the activated carbon microspheres are used as a carbon source, so the preparation method has the advantages of low production cost, simple preparation process and the like; the good dispersity, high activity and the like of the carbon microspheres are beneficial for dispersion and reduction reaction of the carbon microspheres in a matrix; and the high-entropy carbide ceramic prepared by using the method has the characteristics of good mechanical property, high density, high purity, low thermal conductivity and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

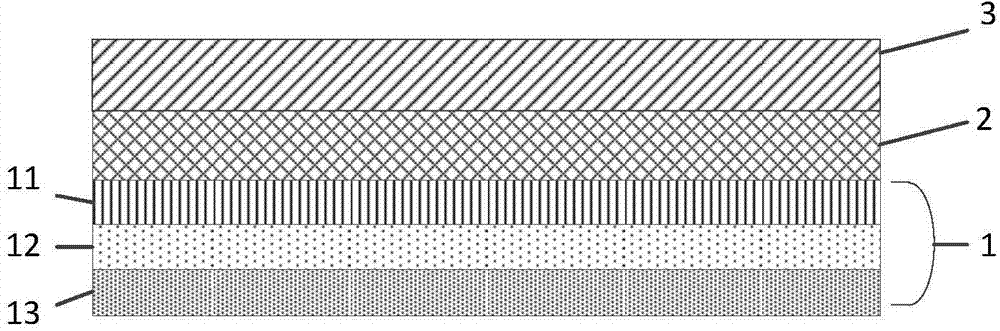

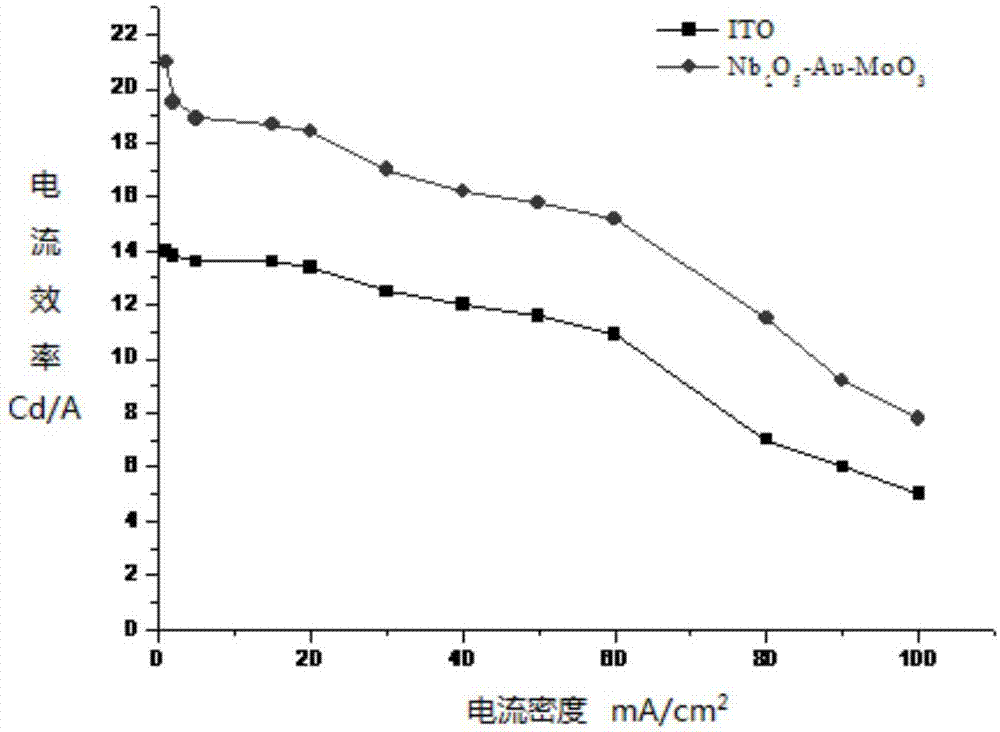

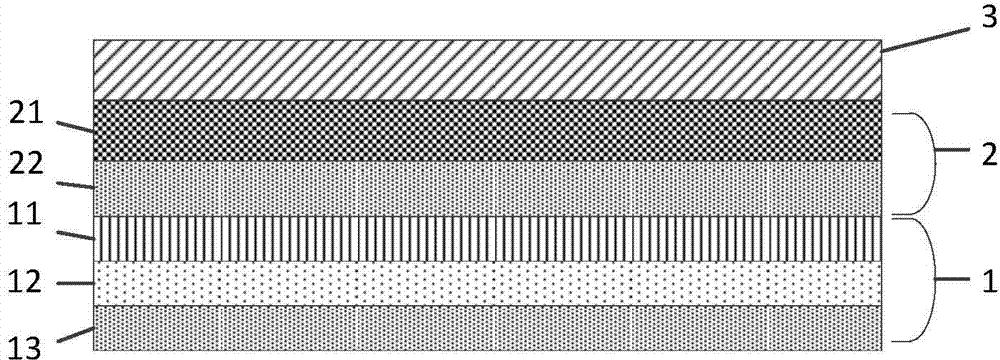

Organic light-emitting display device, manufacturing method thereof and display equipment

ActiveCN104851988AImprove luminous efficiencyAvoid Microcavity EffectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention provides an organic light-emitting display device, which comprises an anode, an organic light-emitting layer and a cathode, wherein the anode comprises a niobium pentaoxide material layer, a gold material layer and a molybdenum trioxide material layer. According to the invention, the anode of the organic light-emitting display device provided by the invention adopts Nb2O5, Au and MoO3 materials, thereby avoiding a microcavity effect caused by adopting ITO as an anode material in the prior art, and enabling the light-emitting efficiency of the light-emitting display device to be effectively improved.

Owner:BOE TECH GRP CO LTD +1

High-performance (TiTaHfZrNb) C high-entropy carbide ceramic and preparation method thereof

The invention discloses high-performance (TiTaHfZrNb) C high-entropy carbide ceramic and a preparation method thereof, and belongs to the technical field of high-entropy ceramic. The high-performance(TiTaHfZrNb) C high-entropy carbide ceramic comprises the following raw materials in parts by weight: 1-2 parts of hafnium oxide micro powder, 1-2 parts of titanium oxide micro powder, 1-2 parts of tantalum pentoxide micro powder, 1-2 parts of zirconium oxide micro powder and 5-6 parts of graphite microspheres. The graphite microspheres adopted by the invention not only have physical and chemicalproperties similar to those of crystalline flake graphite, but also have good sphericity, fluidity and dispersibility, and in addition, the specific surface area of the graphite microspheres is far larger than that of the crystalline flake graphite, so that the graphite microspheres have higher chemical reaction activity. Compared with carbon black which is easy to float on the surface of a matrix, the mass of the graphite microspheres per unit volume is much higher than that of the carbon black, and the graphite microspheres are easier to disperse in the matrix. Therefore, the high-entropy carbide ceramic is prepared from the graphite microspheres through a carbothermic reduction reaction mechanism, and the problems of high synthesis temperature, large grain development and the like of high-entropy carbide are effectively solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing perovskite-type flaky KNN (potassium sodium niobate) with hydrothermal method

The invention discloses a method for preparing perovskite-type flaky KNN (potassium sodium niobate) with a hydrothermal method and belongs to the field of functional ceramic materials. The method is characterized in that sodium hydroxide, potassium hydroxide and niobium pentoxide are used as raw materials, the concentration of alkali liquor is 10 mol / L, the molar ratio of potassium ions to sodium ions is 3:1, the concentration of the niobium pentoxide is 0.035 mol / L, the hydrothermal reaction temperature is 150 DEG C, the stirring speed is 90-150 r / min, the reaction time is 8-36 h, and an initial product is obtained through centrifugal separation. The initial product is placed in a muffle after being dried and then kept at the temperature of 450-600 DEG C for 2-4 h, and the perovskite-type KNN which is in the hexagonal or round-like flake shape, has the thickness of 0.1-0.5 mu m and has the plane size range of 1.5-4.0 mu m is obtained. According to the method, the raw materials are easy to obtain and low in price, equipment is simple, the technology is easy to control, and the method has brighter application prospect in aspects of preparation of two-dimensional KNN materials and KNN piezoelectric ceramic texturing research.

Owner:QIQIHAR UNIVERSITY

Preparation method of potassium-sodium niobate ceramic material with high remnant polarization strength

The invention discloses a preparation method of a potassium-sodium niobate ceramic material with high remnant polarization strength, and relates to a preparation method for improving the remnant polarization strength of K0.5Na0.5NbO3 ceramic. The invention aims to solve the technical problem that the existing lead-free K0.5Na0.5NbO3 ceramic is low in remnant polarization intensity. The method comprises the following steps: mixing dried potassium carbonate and sodium carbonate powder with niobium pentoxide powder and then carrying out wet ball milling; drying, putting the dried raw materials into a tubular furnace for presintering, then carrying out wet ball milling, putting the dried raw materials into a hot-pressing furnace in an oxygen atmosphere for high-temperature and high-pressure sintering, and putting ceramic slices obtained by hot-pressing sintering into the tubular furnace for oxygen annealing so as to obtain the K0.5Na0.5NbO3 ceramic with high remnant polarization strength.The remnant polarization intensity of the ceramic is 24-27 [mu] C / cm < 2 >, which is 1.6-2.7 times that of K0.5Na0.5NbO3 ceramic prepared by a traditional solid-phase method, and the ceramic can be used in the fields of electricity and electronics.

Owner:HARBIN INST OF TECH

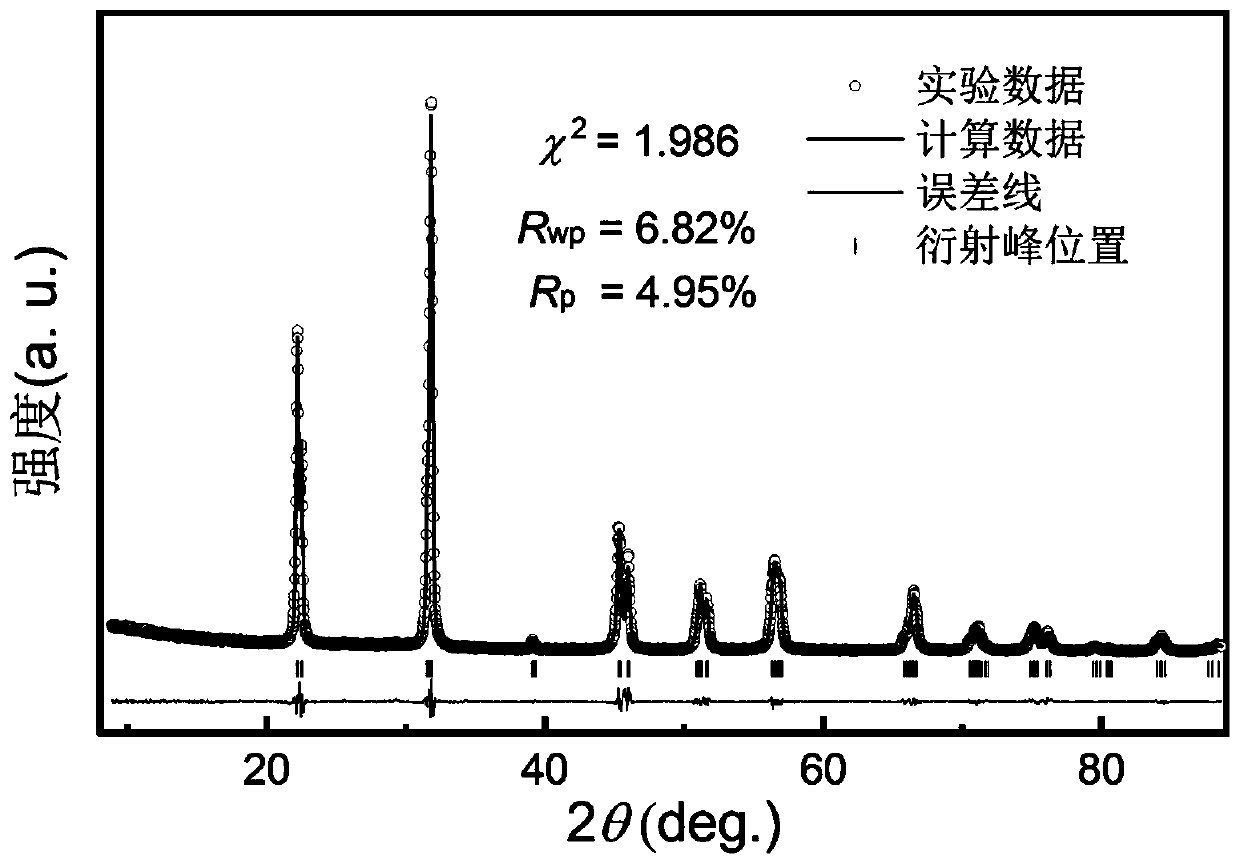

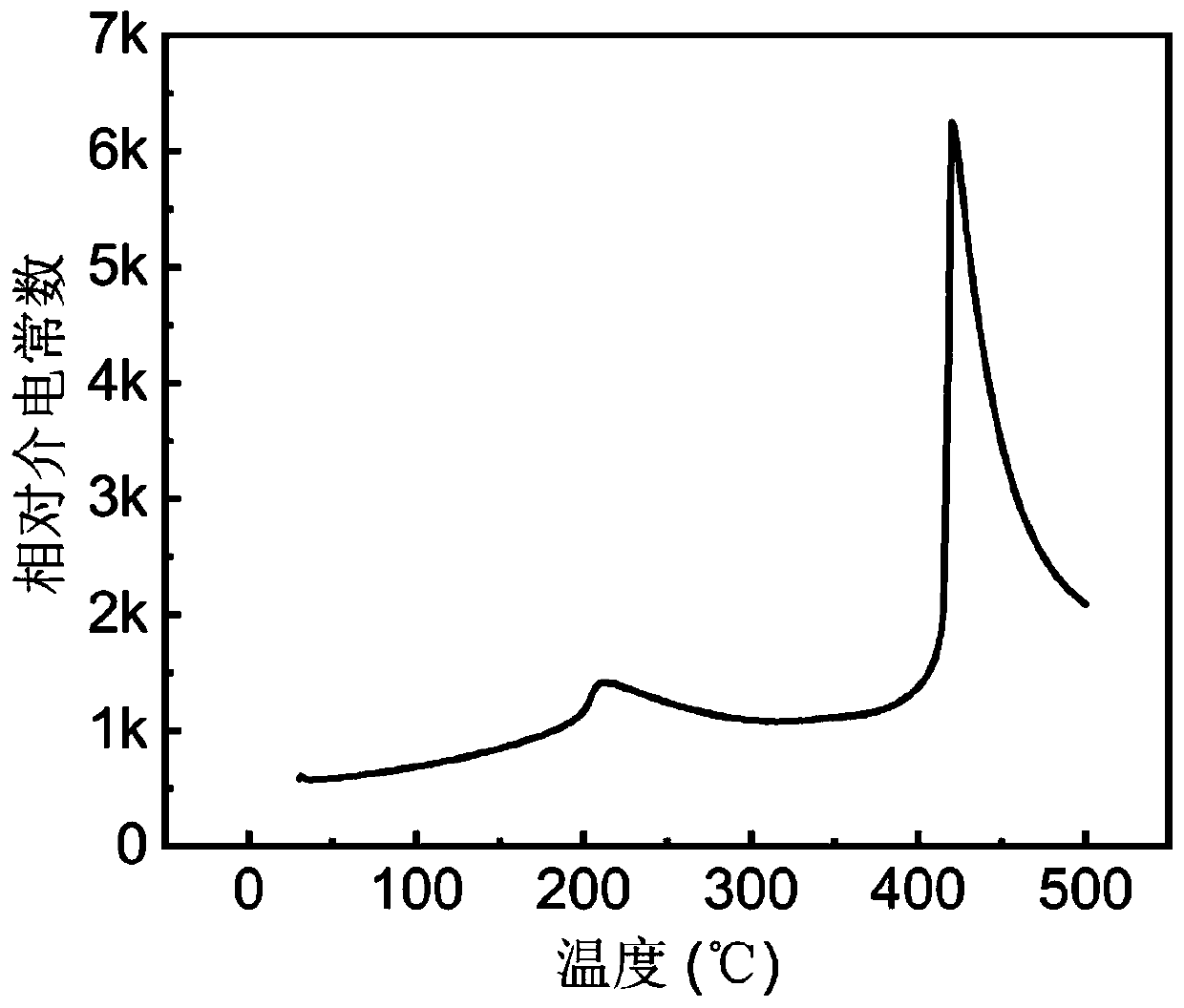

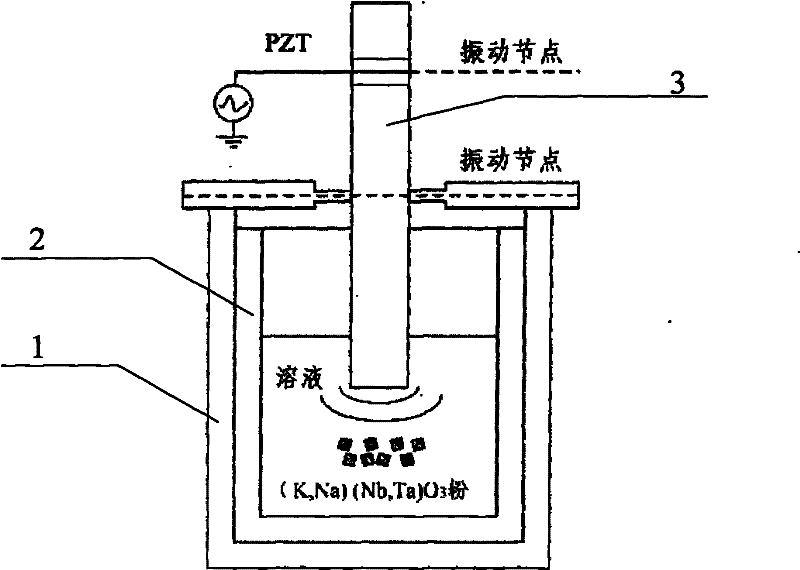

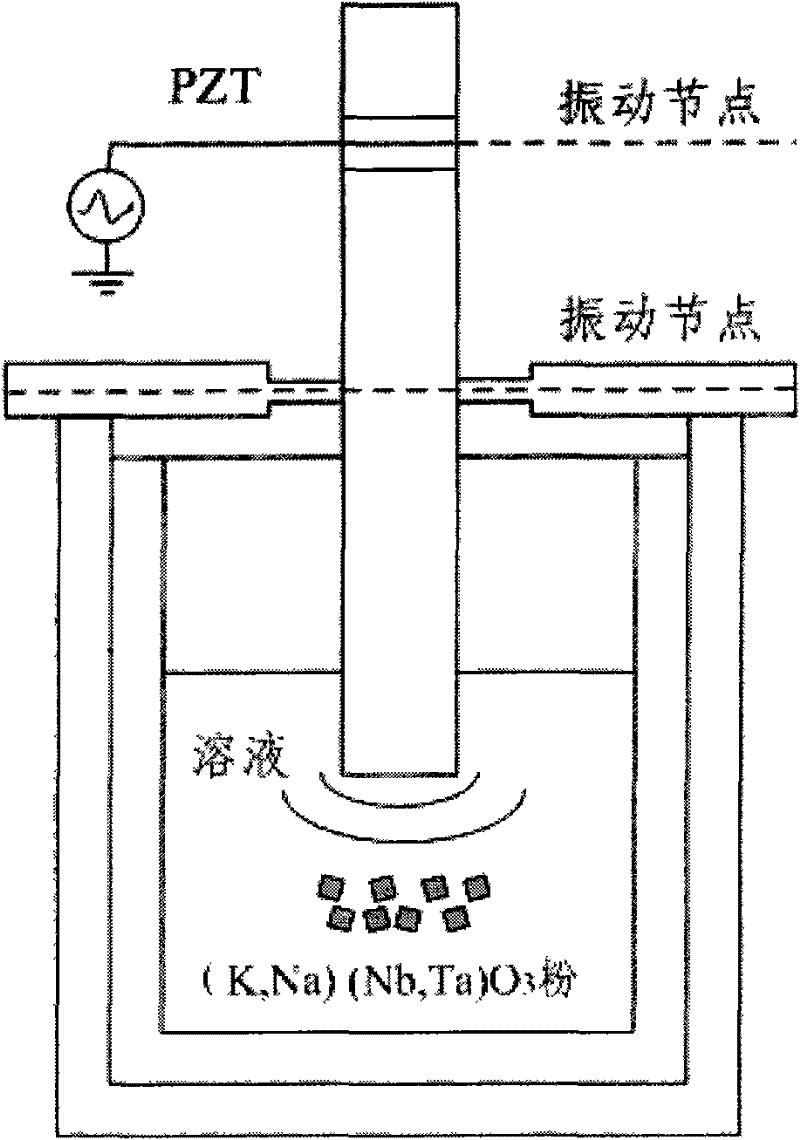

Method for synthesizing nano potassium tantalate niobate powder

InactiveCN102173797AImprove electromechanical performanceProduction process is environmentally friendlyLead zirconate titanateUltrasonic assisted

The invention discloses an ultrasonic assisted thermosynthesis method for preparing nano potassium tantalate niobate powder. The method comprises the following steps: (1) putting alkali liquor prepared from sodium hydroxide and potassium hydroxide in an ultrasonic assisted hydrothermal device; and (2) adding solid oxide consisting of niobium pentaoxide and tantalum oxide to the alkali liquor prepared in the step (1) for reaction. By using the method, the electromechanical properties of the system are greatly improved; and the nano potassium tantalate niobate powder can be used for preparing the lead-free piezoelectric ceramic of the system, wherein the lead-free piezoelectric ceramic is expected to replace lead zirconate titanate series piezoelectric ceramic, is environment-friendly, has more environment-friendly production process and has a good commercial value.

Owner:SHANGHAI MARITIME UNIVERSITY

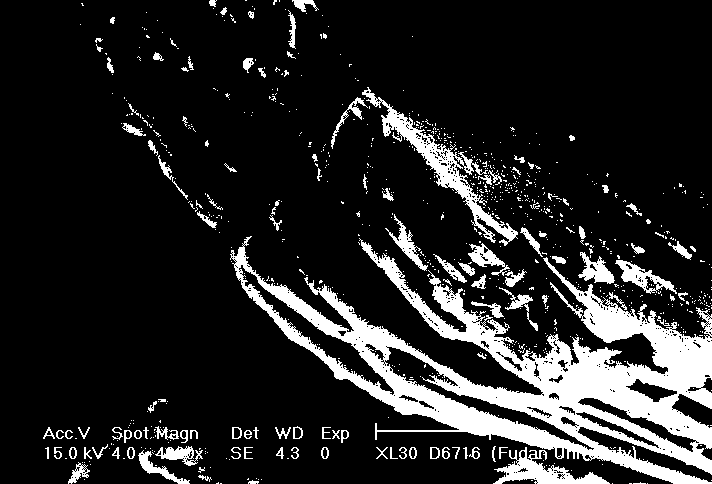

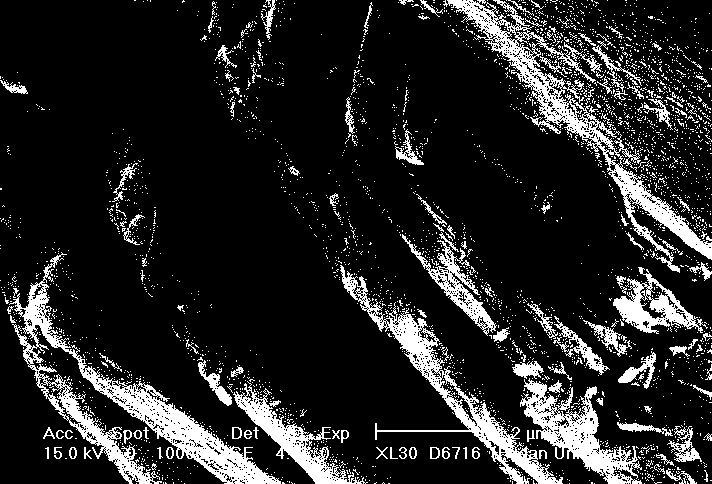

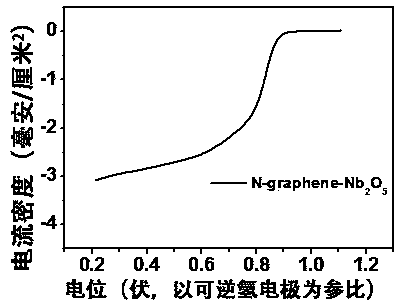

Preparation method for nitrogen doped graphene-niobium pentoxide intercalation composite catalyst with high oxygen reduction performance

InactiveCN103657698AGood catalyticImprove stabilityPhysical/chemical process catalystsPtru catalystNitrogen doped graphene

The invention relates to a preparation method for nitrogen doped graphene-niobium pentoxide intercalation composite catalyst with a high oxygen reduction performance. The method comprises the following steps: mixing niobium pentoxide and potassium carbonate at the molar ratio of (3:1)-(3:1.5), heating to 600-1000 DEG C, keeping for 1 hour, then heating up to 1050-1300 DEG C, keeping for 1-10 hours; washing by hot water; drying for 1-72 hours at the temperature of 100-500 DEG C; placing obtained products in a 10-68wt% nitric acid solution, stirring for 1-7days; repeating for 2-5 times; filtering and washing by distilled water, drying for 1-72 hours at the temperature of 30-80 DEG C; mixing the product with 4-vinyl pyridine at the mass ratio of (1:0.2)-(1:5), then dispersing in water; stirring for 1-7 days at the room temperature; filtering and washing by the distilled water, performing vacuum drying for 1-72 hours at the room temperature; heating to 700-900 DEG C under the argon atmosphere, keeping the temperature for 1-10 hours, cooling and obtaining the target catalyst. The catalyst has extremely excellent catalysis effect in the oxygen reduction reaction, and delivers better stability, higher methanol tolerance and comparative initial potential fall than a conventional representative Pt / C catalyst.

Owner:FUDAN UNIV

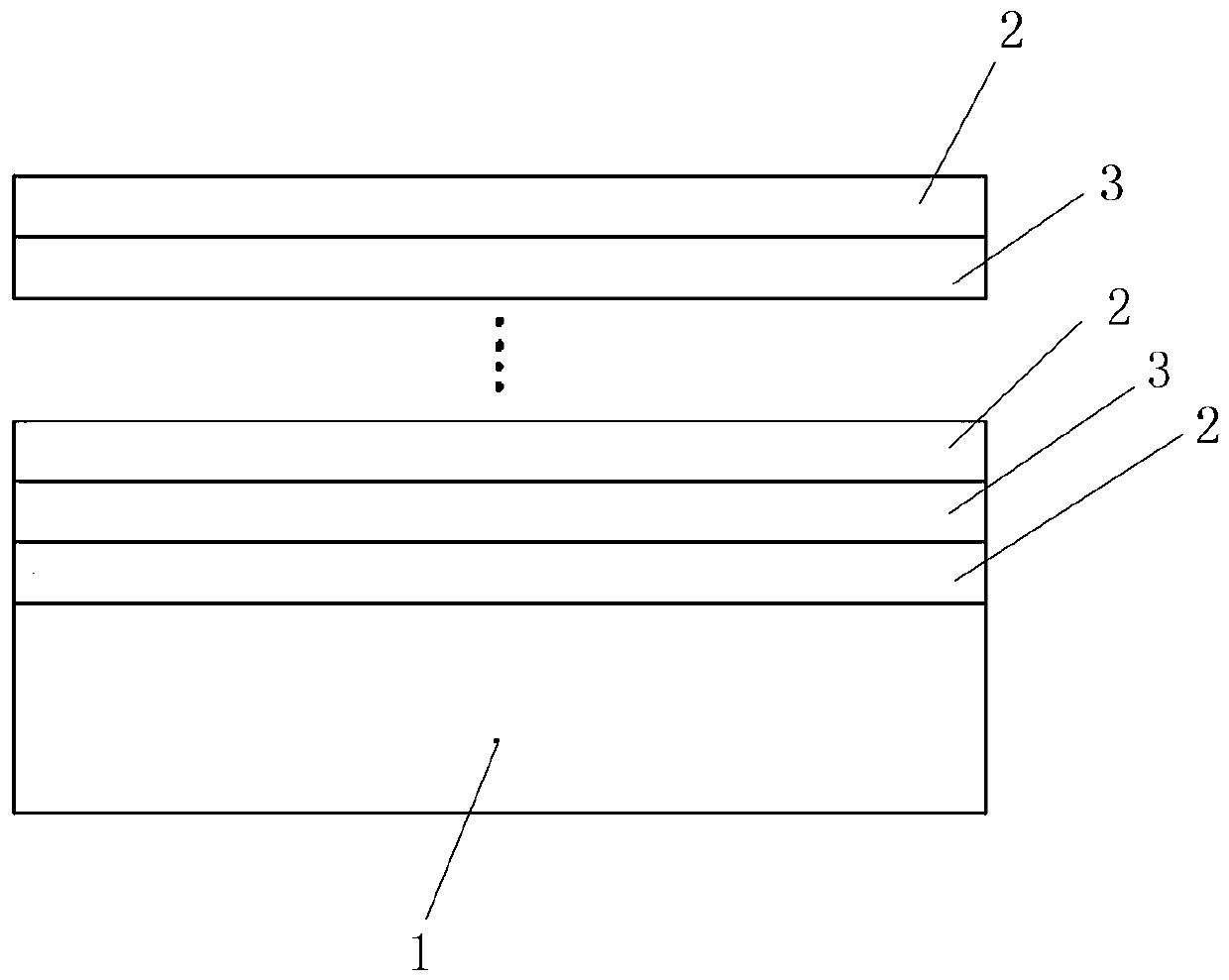

Low-warpage infrared cut-off filter and coating method thereof

PendingCN110196466AAvoid absorbing mildew and other adverse effectsReduce warpage deformationOptical filtersVacuum evaporation coatingComposite filmRefractive index

The invention discloses a low-warpage infrared cut-off filter and a coating method thereof. The low-warpage infrared cut-off filter comprises a substrate and a composite film layer arranged on the surface of the substrate, wherein the composite film layer is made by high refractive index material H layers and low refractive index material L layers which are stacked alternatively; the high refractive index material layer is a titanium dioxide, or trititanium pentoxide, or tantalum oxide, or niobium pentaoxide material layer; the low refractive index material layer is a silica, or alumina, or magnesium fluoride material layer; and the thickness of the composite film layer is 1500 to 9000 nm. Through selection, cleaning, cleaning, coating, parameter inspection, re-cleaning and visual inspection, coating on the infrared cut-off filter is completed. In comparison with the prior art, specially optimized coating parameters are adopted to reduce warpage deformation caused by stress accumulation, the defects such as adsorption mildew spots caused by the conventional coating parameters for reducing the warpage are avoided, and enhancement of the subsequent processing yield is facilitated.

Owner:HENAN DUBANG PHOTOELECTRIC CO LTD

Method for preparing barium zirconate titanate and potassium-sodium niobate composite lead-free piezoelectric thick film

The invention relates to a method for preparing a piezoelectric thick film in inorganic materials, and discloses a method for preparing a barium zirconate titanate and potassium-sodium niobate composite lead-free piezoelectric thick film. The method comprises the following steps: (1) preparing barium zirconate titanate precursor sol in the stoichiometric ratio of BaZr0.5Ti0.95O3; (2) respectively weighing potassium carbonate, sodium carbonate and niobium pentaoxide in the stoichiometric ratio of K0.5Na0.5NbO3, and preparing micro / nanometer grade potassium-sodium niobate through mixed ball milling, drying, tabletting, sintering, crushing and ball milling; (3) mixing the micro / nanometer grade potassium-sodium niobate with the barium zirconate titanate precursor sol to prepare stable mixed size, wherein the mass content of the potassium-sodium niobate is between 40 and 70 percent; and (4) repeating spinning process-heat treatment process to obtain the barium zirconate titanate and potassium-sodium niobate composite lead-free piezoelectric thick film.

Owner:XI AN JIAOTONG UNIV

Novel red-light fluorescent powder and method for preparing same

InactiveCN101205464AHigh color purityHigh color rendering indexLuminescent compositionsLuminous intensityFiltration

The invention provides novel red light-emitting fluorescent powder and a preparation method thereof, wherein the fluorescent powder is obtained through doping Eu<3+> or Eu<3+> and Li<+> in YNbTiO6 substrate; when Eu<3+> is doped alone, the general chemical formula is Y1-xNbTiO6:xEu<3+> with the numeric area of x more than 0.001 and less than 0.35; when both Eu<3+> and Li<+> are doped, the general chemical formula is Y1-x-yNbTiO6:xEu<3+>, yLi<+> with the numeric area of x more than 0.001 and less than 0.35 and the numeric area of y more than 0.001 and less than 0.1. The preparation method includes the following steps: firstly, niobium pentaoxide is dissolved in hydrofluoric acid and then ammonia water is instilled in the solution for neutralization; secondly, after aging, filtration and cleaning, the niobium hydroxide deposit is dissolved in citric acid aqueous solution; thirdly, tetrabutyl titanate, yttrium nitrate, europium nitrate, lithium nitrate and ammonium nitrate which are added in the citric acid solution in turn are heated up and stirred; finally, sintering and thermal annealing treatments to the obtained precursor gel are completed. The red light-emitting fluorescent powder prepared by the invention has high color purity, high color rendering index and strong luminous intensity.

Owner:SHANDONG UNIV

Method of preparing magnesium-niobate

InactiveCN101367552APrevent volatilizationShort reaction timeNiobium compoundsChemical reactionLead oxide

The invention discloses a method for preparing magnesium niobium oxide, which comprises the following steps: magnesium oxide (MgO) is mixed with niobium pentaoxide (Nb2O5) according to the dose of the mole ratio of 1:1, and the mixture is arranged inside a screw grinding machine to be ground for 6 to 11 hours; or after the magnesium oxide (MgO) is mixed with niobium pentaoxide (Nb2O5) at the same proportional ratio, the mixture is added with de-ionized water that can dip the mixture, and after the mixed solution is ground and uniformly mixed in a mortar, and the mixture is arranged into an oven to be dried until the mixture is slightly dry in the temperature of 80 to 100 DEG C; the slight dried mixture is ground in the screw grinding machine for 5 to 8 hours to get the magnesium niobium oxide with the ordinary chemical formula of MgNb2O6. The prepared magnesium niobium oxide can be reacted with lead monoxide to synthesize the magnesium niobium oxide lead iron electrical material, thus can greatly shorten the reaction time of the synthesis, and also can effectively prevent the volatilization of the lead composition in the reaction process, and can realize the pollution-free chemical reaction. The invention has the advantages of simple craftwork, easy operation, short preparation time, pure material phase, good dispersion, uniform particles, and the like.

Owner:EAST CHINA NORMAL UNIV

Niobium pentaoxide doped cerium dioxide preparation method and product and application thereof

ActiveCN107812516AHigh activitySimple ingredientsIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsOxalateCombustion

The invention provides a niobium pentaoxide doped cerium dioxide preparation method and a product and application thereof. The material is prepared by the steps of respectively dissolving niobium oxalate and cerous nitrate, adding a citric acid combustion improver and a polyvinyl alcohol solubilizer and putting into a muffle furnace to be simply roasted. The material is prepared from Nb2O5 with amass ratio of 1% to 3% and CeO2 with a mass ratio of 97% to 99%. The material is prepared by the steps of respectively dissolving the niobium oxalate and the cerous nitrate, adding the citric acid combustion improver and the polyvinyl alcohol solubilizer and putting into the muffle furnace to be simply roasted. The method disclosed by the invention has the advantages of convenience in preparation,no precipitator, 100% utilization in metal oxide, no waste liquid and waste residue generation and the like. The material further has excellent oxidation susceptibility and can serve as a catalyst ora carrier to be applied to varieties of reactions.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com