Method for testing niobium content in niobium-iron alloy

A technology of ferroniobium alloy and content, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of cumbersome operation steps, not enough environmental protection, inaccurate calculation, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

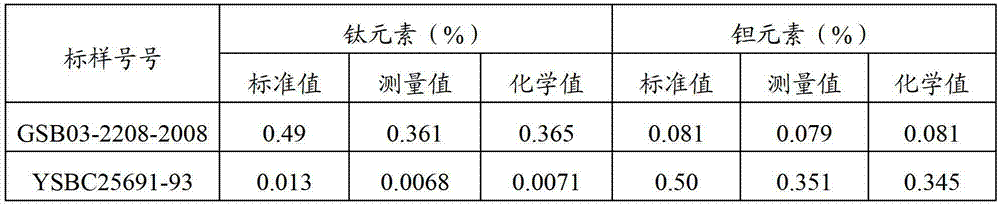

[0020] Determination method of niobium content in ferroniobium alloy: After dissolving ferroniobium alloy, first add precipitant to precipitate niobium in ferroniobium alloy as niobium pentoxide, but at the same time, a part of titanium and tantalum will co-precipitate in niobium pentoxide precipitation , so as long as the content of titanium and tantalum in the precipitation of niobium pentoxide is accurately measured, the content of niobium in ferroniobium alloy can be calculated.

[0021] The general idea of measuring the content of titanium and tantalum in niobium pentoxide precipitation is as follows: melt the niobium pentoxide precipitation sample in a muffle furnace with potassium pyrosulfate, extract it with tartaric acid, set the volume to a certain volume, and introduce the atomized solution into the inductor Coupled with a plasma atomic emission spectrometer, the spectral line intensity of the element to be measured is measured; according to the spectral line inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com