Method of preparing magnesium-niobate

A technology of magnesium niobate and magnesium oxide, which is applied in chemical instruments and methods, niobium compounds, inorganic chemistry and other directions, can solve the problems of low efficiency of synthesis process, insufficient power, low yield and the like, and achieves simple preparation method, low cost and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] a), weigh MgO 10.0689g, Nb 2 o 5 66.3723 g.

[0012] b) Grind and mix the above-mentioned substances in a mortar evenly.

[0013] c), put it into the screw grinder, set the inverter frequency parameter to 30HZ, grind for 11 hours to get MgNb 2 o 6 .

Embodiment 2

[0015] a), weigh MgO 10.1256g, Nb 2 o 5 66.8547g.

[0016] b) Add 20ml of deionized water as a solvent to the above-mentioned substances (the amount added should be such that the mixture can be uniformly dispersed), and grind and mix them evenly in a mortar.

[0017] c) Put the mixture into an oven and bake at 80° C. for 2 hours.

[0018] d), put it into the screw grinder, set the inverter frequency parameter to 40HZ, grind for 8 hours to get MgNb 2 o 6 .

Embodiment 3

[0020] a), weigh MgO 10.2564g, Nb 2 o 5 66.5782 g.

[0021] b) Add 20ml of deionized water as a solvent to the above-mentioned substances (the amount added should be such that the mixture can be uniformly dispersed), and grind and mix them evenly in a mortar.

[0022] c) Put the mixture into an oven and bake at 100° C. for 1.5 hours.

[0023] d), put it into the screw grinder, set the inverter frequency parameter to 50HZ, grind for 5 hours to get MgNb 2 o 6 .

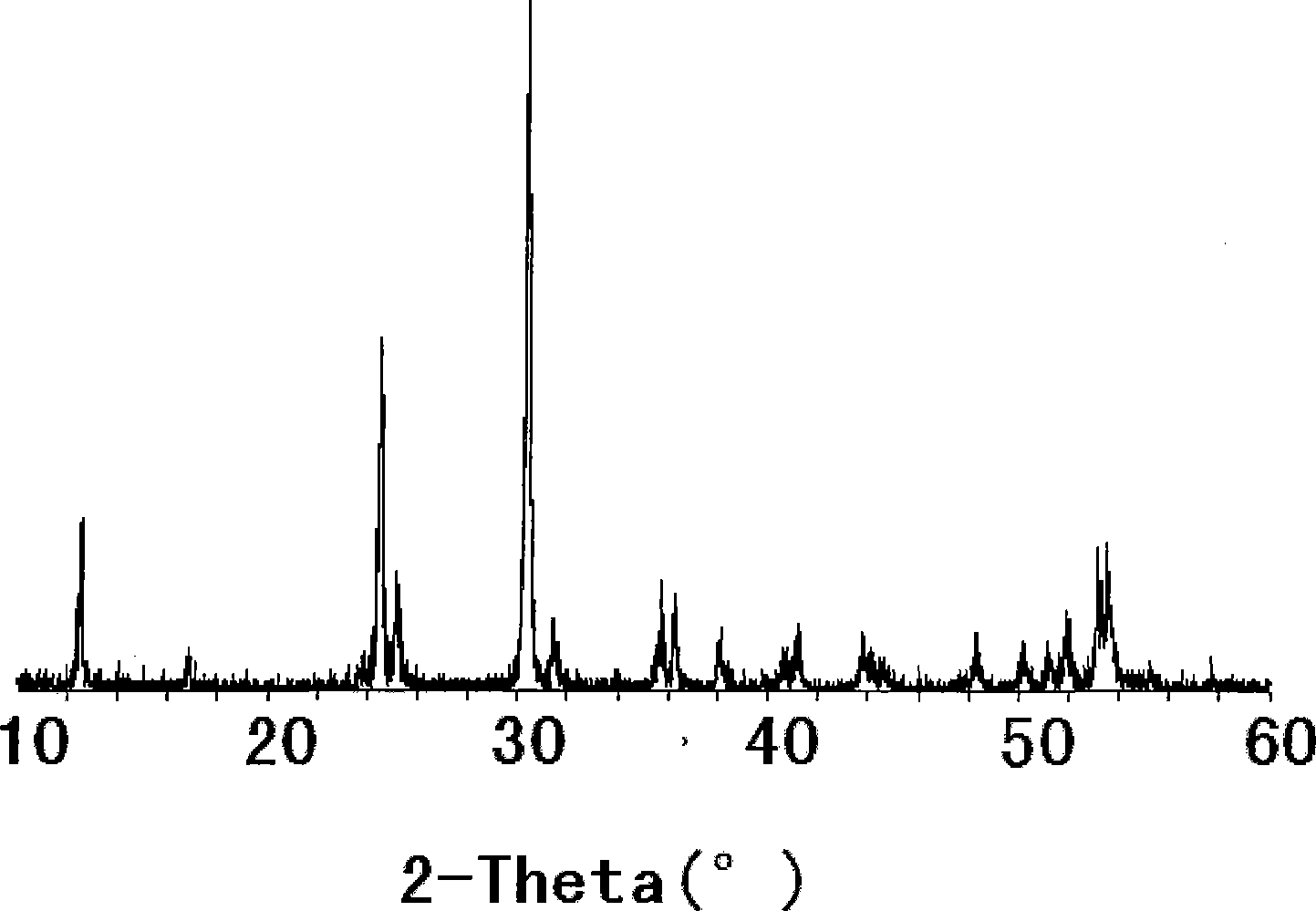

[0024] From attached Figure 1-2 It can be seen that the obtained MgNb 2 o 6 The reaction time is short, the phase is pure, the particles are small, and the dispersion is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com