Normal-pressure densification method of sodium potassium niobate-based leadless piezoelectric ceramic

A potassium-sodium niobate-based, lead-free piezoelectric technology, which is applied in the field of normal pressure densification of potassium-sodium niobate-based lead-free piezoelectric ceramics, can solve the problems of material size limitation, harsh production process, and high production cost, and achieve Good piezoelectric performance, lower sintering temperature, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

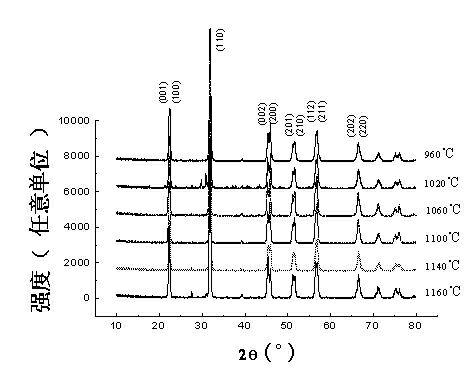

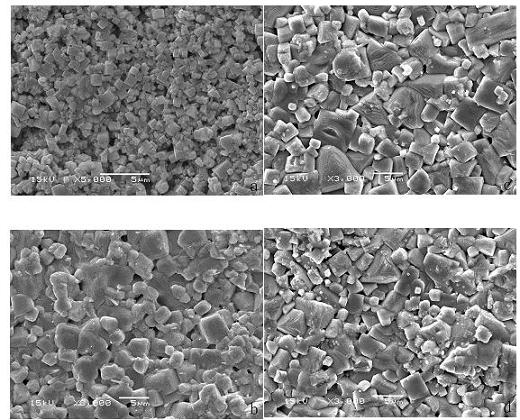

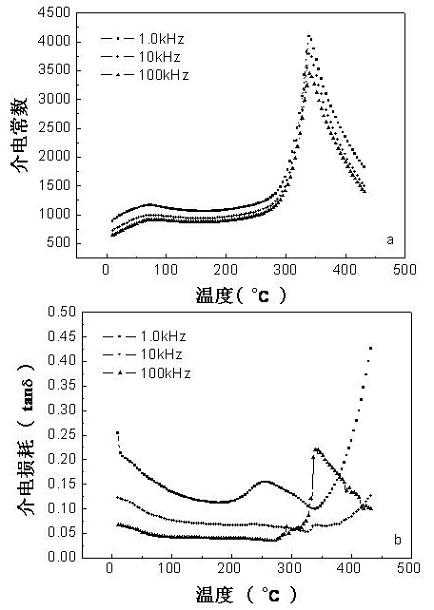

[0023] Prepared by atmospheric sintering process (1-x)(Na 1 / 2 K 1 / 2 )NbO 3 -xCaTiO 3 ((1-x)NKN-xCT, x=0.0025-0.2) Potassium sodium niobate based lead-free piezoelectric ceramics, analysis of pure carbonate Na 2 CO 3 (> 99.8%), K 2 CO 3 (> 99.0%), CaCO 3 (> 99.0%) and oxide Nb 2 O 5 (> 99.5%), TiO 2 (> 99.9%) as the raw material, fully dry the raw material before weighing, the specific steps are: to prepare 0.95 (Na 1 / 2 K 1 / 2 )NbO 3 -0.05CaTiO 3 (0.95NKN-0.05CT) ceramics as an example, the second element CaTiO 3 The addition amount is 5% of the sum of the amount of the raw materials and the second component (batch):

[0024] (1) Weigh 1.4828 grams of Na 2 CO 3 , 1.9489 grams of K 2 CO 3 , 0.2947g CaCO 3 , 7.4576 grams of Nb 2 O 5 And 0.2399 g TiO 2 As raw materials, put them into a polytetrafluoroethylene ball mill tank after mixing, use acetone as the grinding medium, and use ZrO 2 As a grinding ball, wet ball milling for 24 hours, the slurry is filtered, washed, and dried to obtain...

Embodiment 2

[0028] Prepared by atmospheric sintering process (1-x)(Na 1 / 2 K 1 / 2 )NbO 3 -xLiSbO 3 ((1-x)NKN-xLS, x=0.0025-0.2) Potassium sodium niobate based lead-free piezoelectric ceramics, analysis of pure carbonate Na 2 CO 3 (> 99.8%), K 2 CO 3 (> 99.0%), Li 2 CO 3 (> 98.0%) and oxide Nb 2 O 5 (> 99.5%), Sb 2 O 3 (> 99.0%) as the raw material, fully dry the raw material before weighing, the specific steps are: to prepare 0.95 (Na 1 / 2 K 1 / 2 )NbO 3 -0.05LiSbO 3 (0.95NKN-0.05LS) ceramics as an example, the second component LiSbO 3 The addition amount is 5% of the amount of the batch material:

[0029] (1) Weigh 1.4646 grams of Na 2 CO 3 , 1.9256 grams of K 2 CO 3 , 0.1095 g Li 2 CO 3 , 7.3699 grams of Nb 2 O 5 And 0.4275 grams of Sb 2 O 3 As raw materials, put them into a polytetrafluoroethylene ball mill tank after mixing, use acetone as the grinding medium, and use ZrO 2 As a grinding ball, wet ball milling for 24 hours, the slurry is filtered, washed, and dried to obtain a uniformly mixed ba...

Embodiment 3

[0033] Prepared by atmospheric sintering process (1-x)(Na 1 / 2 K 1 / 2 )NbO 3 -xLiTaO 3 ((1-x)NKN-xLT, x=0.0025-0.2) Potassium sodium niobate-based lead-free piezoelectric ceramics, analysis of pure carbonate Na 2 CO 3 (> 99.8%), K 2 CO 3 (> 99.0%), Li 2 CO 3 (> 98.0%) and oxide Nb 2 O 5 (> 99.5%), Ta 2 O 5 (> 99.0%) as the raw material, fully dry the raw material before weighing, the specific steps are: to prepare 0.95 (Na 1 / 2 K 1 / 2 )NbO 3 -0.05LiTaO 3 (0.95NKN-0.05LT) ceramics as an example, the second component LiTaO 3 The addition amount is 5% of the amount of the batch material:

[0034] (1) Weigh 1.7288 grams of Na 2 CO 3 , 2.2713 g K 2 CO 3 , 0.1296 g Li 2 CO 3 , 8.6945 grams of Nb 2 O 5 And 0.7573 grams of Ta 2 O 5 As raw materials, put them into a polytetrafluoroethylene ball mill tank after mixing, use acetone as the grinding medium, and use ZrO 2 As a grinding ball, wet ball milling for 24 hours, the slurry is filtered, washed, and dried to obtain a uniformly mixed batch;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com