Low-warpage infrared cut-off filter and coating method thereof

An infrared cut-off and warpage technology, applied in the field of optical filters, can solve the problems of large warpage of infrared cut-off filters and low-warp infrared cut-off filters, so as to avoid absorption of mildew and reduce warpage Curvature deformation, easy yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings.

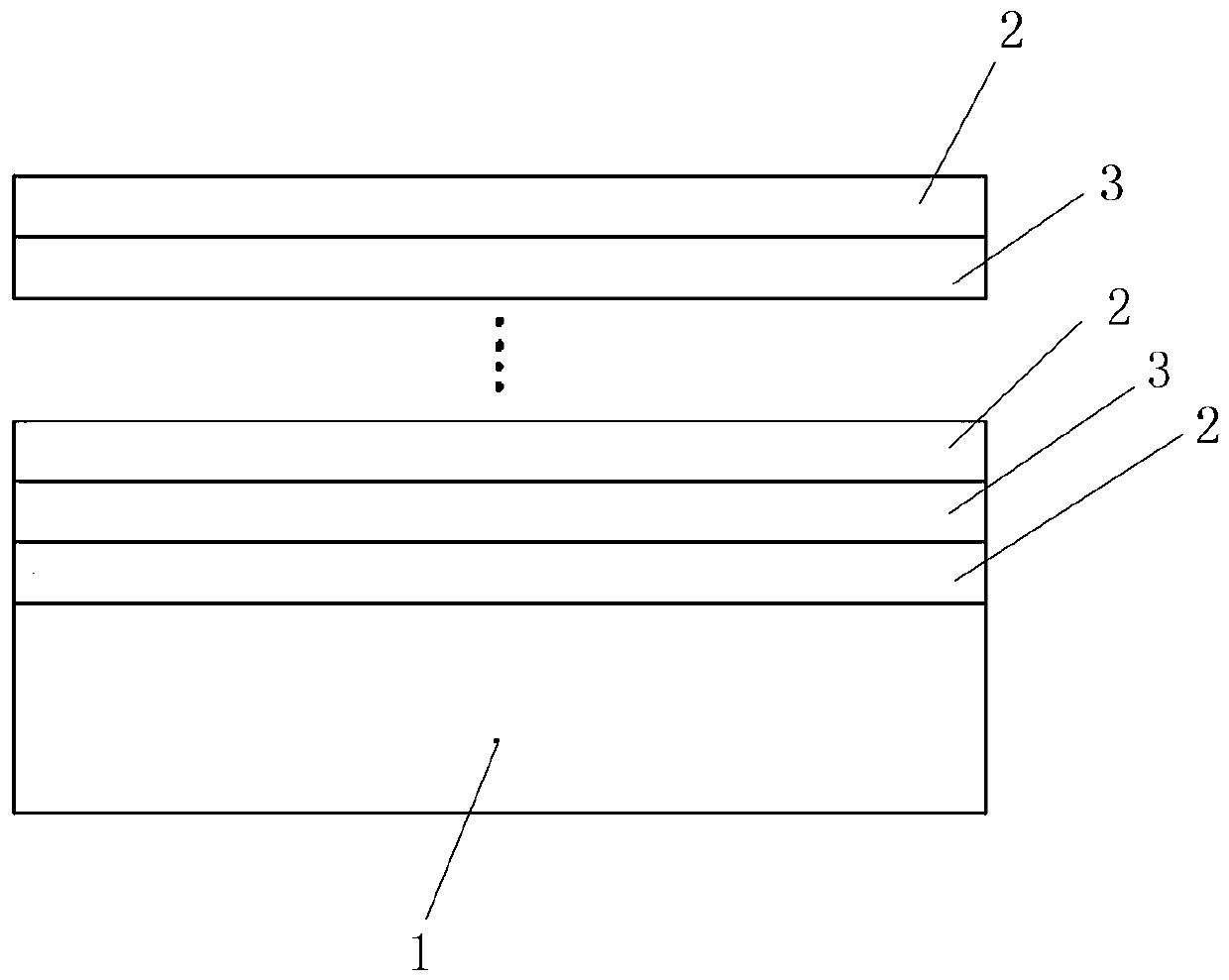

[0027] attached figure 1 It is an embodiment of the present invention, which discloses a low-warpage infrared cut-off filter, including a substrate and a composite film layer arranged on the surface of the substrate, the substrate is glass or plastic or ceramic or optical fiber substrate, The composite film layer is made of alternately laminated high-refractive-index material layers and low-refractive-index material layers, and the high-refractive index material layer is a material layer of titanium dioxide, trititanium pentoxide, tantalum pentoxide or niobium pentoxide , the low refractive index material layer is silicon dioxide, aluminum oxide or magnesium fluoride material layer.

[0028] The thickness of the high refractive index material layer is 5-200nm.

[0029] The thickness of the low refractive index material layer is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com