Solid phase synthetic method of niobate-titanate nano-powder

A nano-powder, solid-phase synthesis technology, applied in the field of functional ceramics, can solve problems such as difficulty in large-scale industrialization and poor compatibility, and achieve the effects of reducing pollution, expanding production capacity, and increasing chemical reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

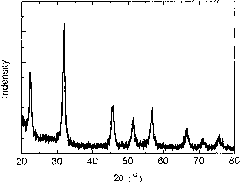

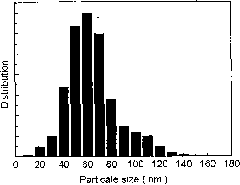

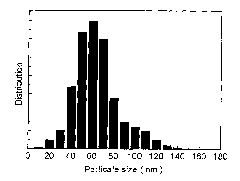

[0012] Put niobium pentoxide, sodium carbonate, potassium carbonate, titanium dioxide, and bismuth trioxide into separate nylon jars for ball milling, the mass of the added powder is 8% of the mass of the zirconia ball, and the speed is 400 rpm , the ball milling time is 8 hours; the ball milling medium is absolute ethanol. The raw material for ball milling is 0.8[(Na 0.5 K 0.5 )NbO 3 ]-0.2(Bi 0.5 Na 0.5 )TiO 3 ] The ingredients are put into the ball mill jar; the zirconia ball and the nylon jar are selected; the mass of the added powder is 8% of the ball mass; the ball milling time is 6 hours, the rotating speed is 420 rpm, and the ball milling medium is absolute ethanol. The obtained product was baked in an oven at 80°C for 2 hours, and pre-fired at 760°C for 2 hours; the pre-fired powder was taken out and ground, and ball milled again for 2 hours; passed through a 120-mesh sieve. Use X-ray diffraction to identify the phase and crystal structure of the powder and calcu...

Embodiment 2

[0014] Put niobium pentoxide, sodium carbonate, potassium carbonate, titanium dioxide, and bismuth trioxide into separate nylon tanks for ball milling, the mass of the added powder is 12% of the mass of the zirconia ball, and the speed is 430 rpm , the ball milling time is 4 hours; the ball milling medium is absolute ethanol. The raw material for ball milling is 0.1[(Na 0.5 K 0.5 )NbO 3 ]-0.9(Bi 0.5 Na 0.5 )TiO 3 ] The ingredients are put into the ball mill jar; the zirconia ball and the nylon jar are selected; the mass of the added powder is 4% of the ball mass; the ball milling time is 2 hours, the rotating speed is 320 rpm, and the ball milling medium is absolute ethanol. The obtained product was baked in an oven at 60°C for 3 hours, and pre-fired at 660°C for 3 hours; the pre-fired powder was taken out and ground, ball milled again for 2 hours; passed through a 120-mesh sieve. Use X-ray diffraction to identify the phase and crystal structure of the powder and calcula...

Embodiment 3

[0016] Put niobium pentoxide, sodium carbonate, potassium carbonate, titanium dioxide, and bismuth trioxide into separate tungsten carbide pots for ball milling, the mass of the added powder is 5% of the mass of the tungsten carbide ball, and the speed is 420 rpm Minutes, the ball milling time is 2 hours; the ball milling medium is absolute ethanol. The raw materials for ball milling are stoichiometrically (Na 0.5 K 0.5 )NbO 3 Put the ingredients into the ball mill jar; select tungsten carbide balls and tungsten carbide jars; the mass of the added powder is 4% of the ball mass; the ball milling time is 2 hours, the speed is 400 rpm, and there is no ball milling medium. The obtained product was baked in an oven at 80°C for 1 hour, and pre-fired at 840°C for 2 hours; the pre-fired powder was taken out and ground, and ball milled again for 2 hours; passed through a 120-mesh sieve. Use X-ray diffraction to identify the phase and crystal structure of the powder and calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com