Preparation method of spherical nanoscale niobium pentaoxide powder

A nano-scale technology of niobium pentoxide, which is applied in the field of preparation of spherical nano-scale niobium pentoxide powder, can solve problems such as difficulty in preparing uniform nano-niobium oxide, difficulty in ensuring safety, and harsh process conditions, etc., to achieve Light agglomeration, safe process and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

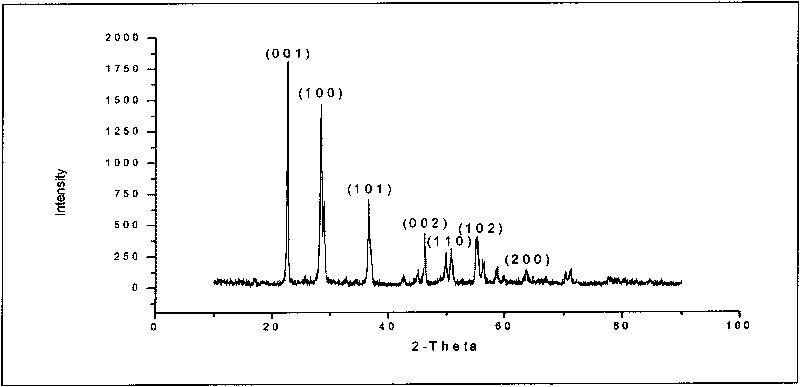

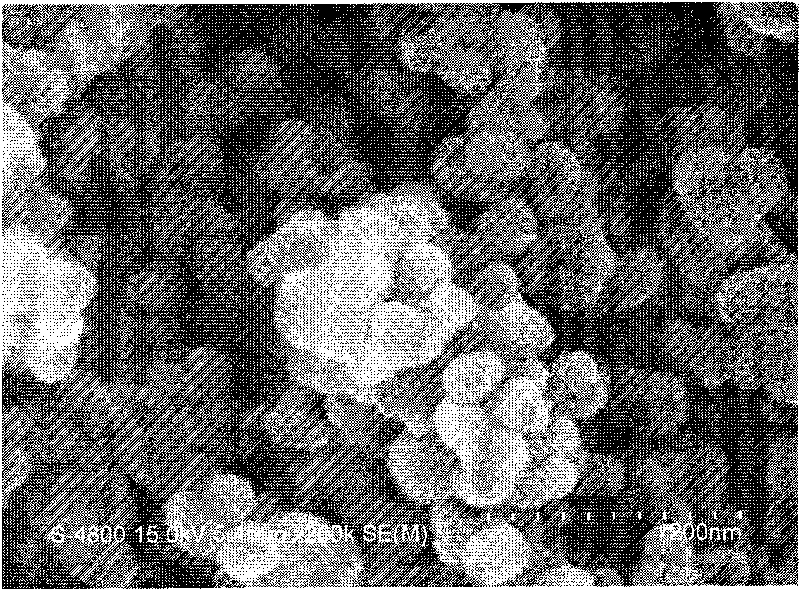

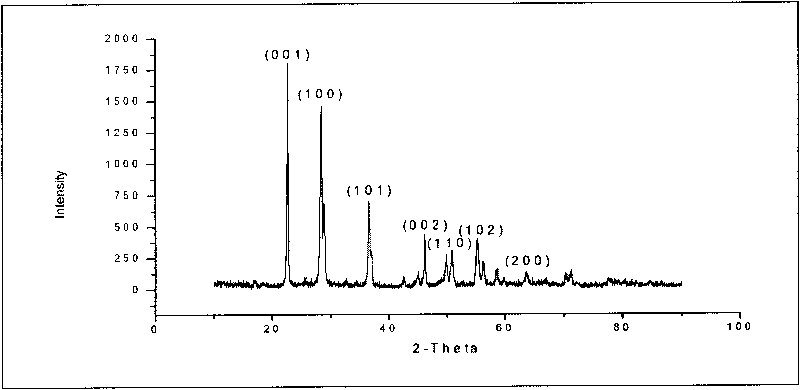

Image

Examples

Embodiment 1

[0040] Preparation of niobium oxalate solution: heating and boiling niobium hydroxide and oxalic acid in distilled water for 1 hour, stirring constantly, stirring at a speed of 450 revolutions per minute, and then using a common funnel to filter under normal pressure. The clear liquid obtained is the niobium oxalate solution; The mass ratio of niobium hydroxide and oxalic acid is 1:3, the mass ratio of niobium hydroxide and distilled water is 1:300; the concentration of niobium oxalate expressed as niobium pentoxide is 10.45mg (Nb 2 O 5 ) / ml.

[0041] The concentration of niobium oxalate expressed as niobium pentoxide is calculated according to the following method:

[0042] Take 5ml, 10ml, and 20ml niobium oxalate solution respectively, volatilize the water between 70~80℃ to obtain white crystals, then place the white crystals in a muffle furnace at 800℃ and calcinate for 2 hours, after cooling to obtain white powder (this The white powder is tested as niobium pentoxide), weigh th...

Embodiment 2

[0048] Preparing niobium oxalate solution: heating and boiling niobium hydroxide and oxalic acid in distilled water for 2 hours, stirring constantly, stirring at a speed of 400 revolutions per minute, and then filtering with an ordinary funnel under normal pressure, and the clear liquid obtained is the niobium oxalate solution; The mass ratio of niobium hydroxide and oxalic acid is 1:4, the mass ratio of niobium hydroxide and distilled water is 1:400; the concentration of niobium oxalate expressed as niobium pentoxide is 12.18mg (Nb 2 O 5 ) / ml. The calculation method of the concentration of niobium oxalate expressed as niobium pentoxide is the same as in Example 1.

[0049] First, the carbon black is boiled for 2 hours with a 2mol / l sodium hydroxide solution, and then vacuum filtered and dried; 4 grams of carbon black, 82.1ml of niobium oxalate solution and 206.2ml of ethylene glycol (pentoxide The loading of niobium is 20%), and the pH value is adjusted to 8.5 with ammonia water...

Embodiment 3

[0054] Preparing the niobium oxalate solution: heating and boiling niobium hydroxide and oxalic acid in distilled water for 3 hours, stirring constantly at a stirring speed of 350 revolutions per minute, and then using a common funnel to filter under normal pressure, and the clear liquid obtained is the niobium oxalate solution; The mass ratio of niobium hydroxide and oxalic acid is 1:5, the mass ratio of niobium hydroxide and distilled water is 1:500; the concentration of niobium oxalate expressed as niobium pentoxide is 15.37mg (Nb 2 O 5 ) / ml. The calculation method of the concentration of niobium oxalate expressed as niobium pentoxide is the same as in Example 1.

[0055] First, the carbon black is boiled for 2 hours with a 2mol / l sodium hydroxide solution, and then vacuum filtered and dried; 4 grams of carbon black, 110.6ml of niobium oxalate solution and 221.2ml of ethylene glycol are mixed (pentoxide The loading of niobium is 30%), and the pH value is adjusted to 8 with amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com