Preparation method of potassium-sodium niobate ceramic material with high remnant polarization strength

A technology of polarization strength and potassium sodium niobate, which is applied in the field of preparation of K0.5Na0.5NbO3 ceramic remanent polarization strength, can solve the problem of low remanent polarization strength of ceramics, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

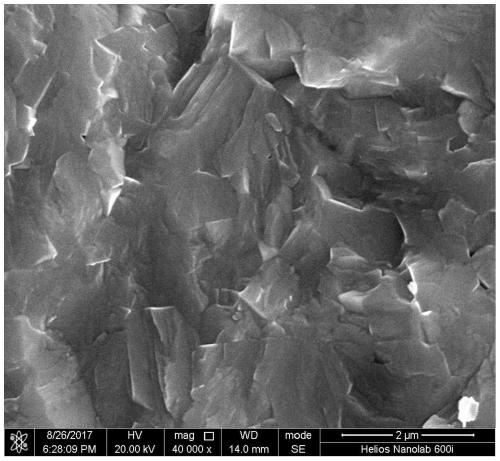

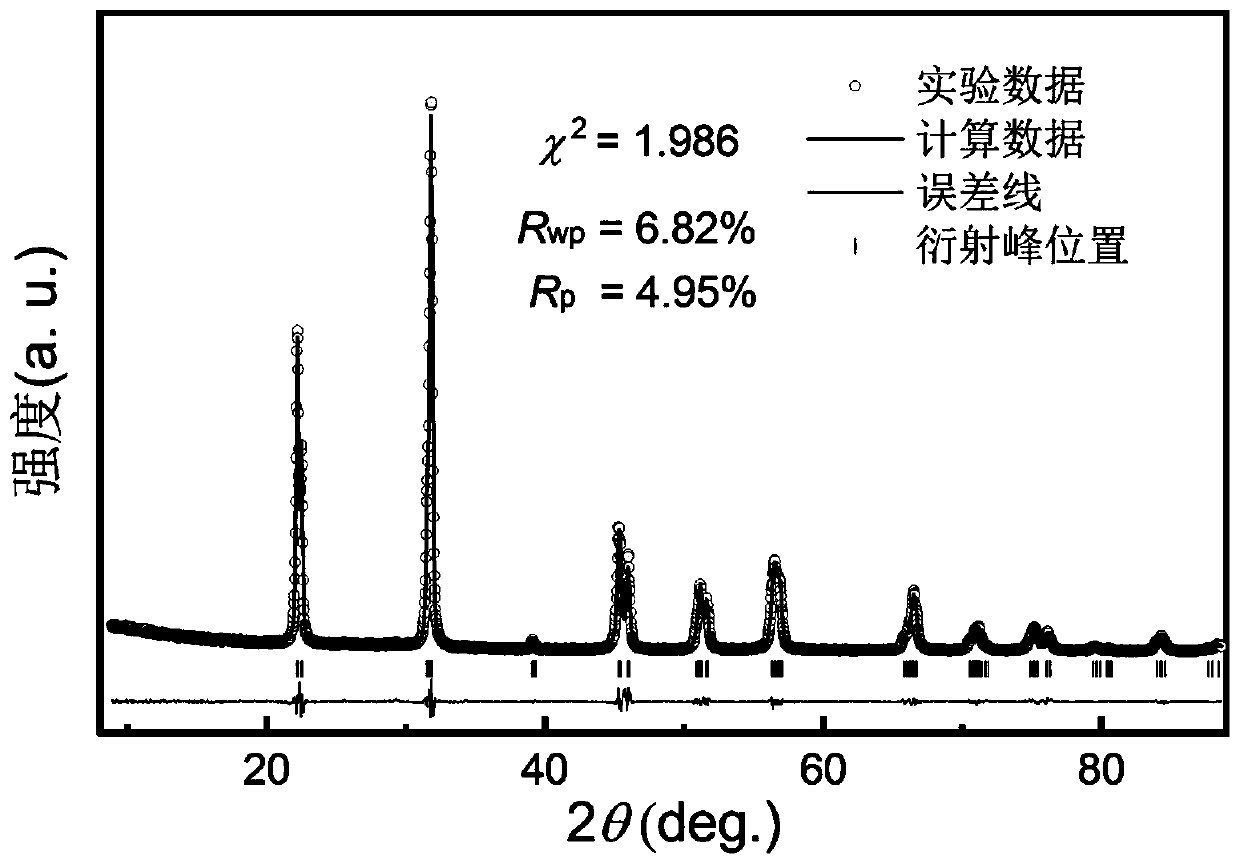

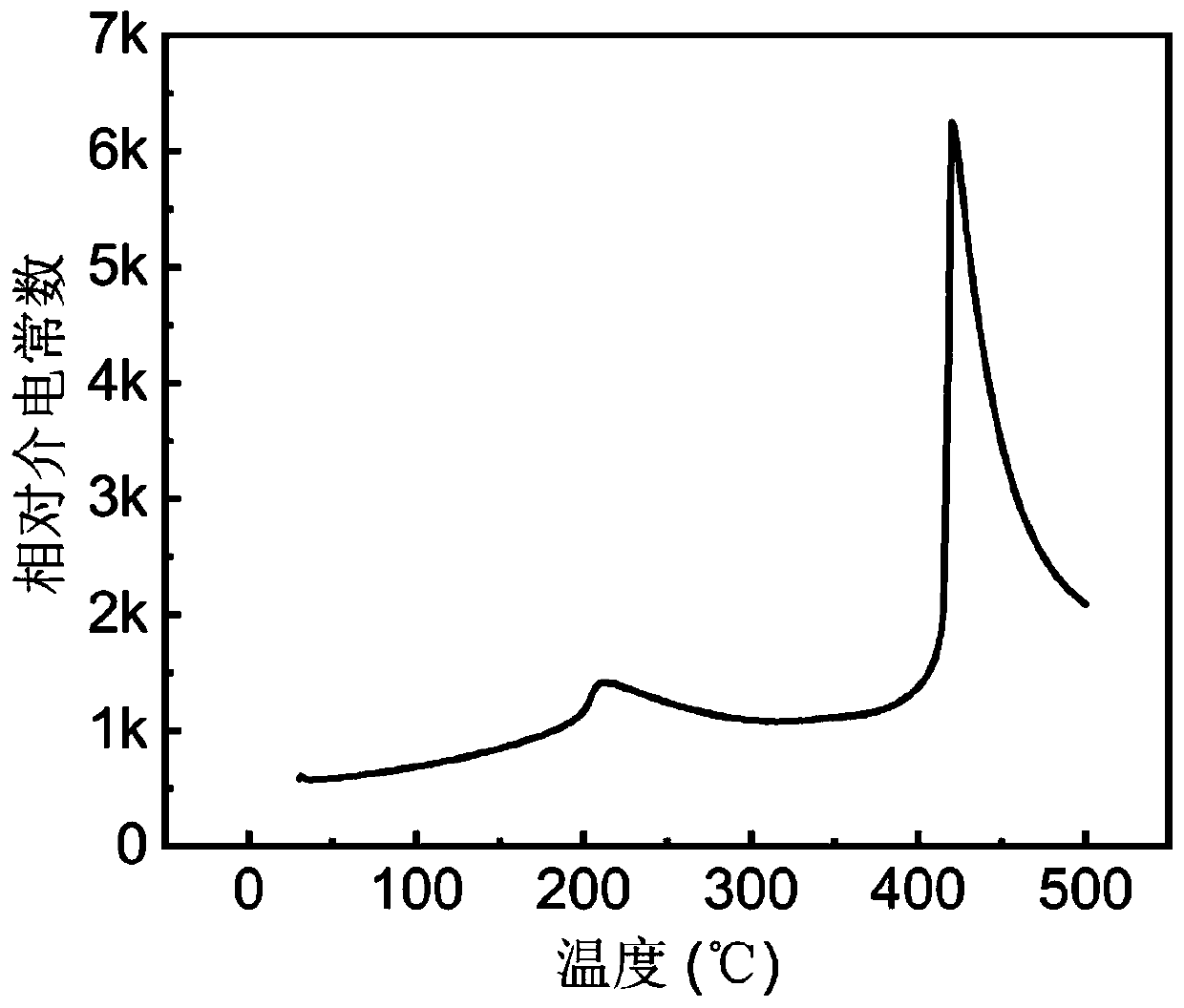

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of the potassium sodium niobate ceramic material with high remnant polarization of the present embodiment, carries out according to the following steps:

[0020] Two, potassium carbonate (K 2 CO 3 ) and sodium carbonate (Na 2 CO 3 ) powders are respectively placed in an oven and heated to remove moisture;

[0021] 2. Potassium carbonate (K 2 CO 3 ) and sodium carbonate (Na 2 CO 3 ) powder and niobium pentoxide (Nb 2 o 5 ) powder according to K 0.5 Na 0.5 NbO 3 The stoichiometric ratio is weighed and mixed uniformly to obtain a mixed powder;

[0022] 3. Add alcohol to the mixed powder obtained in step 2, and ball mill in a ball mill at a speed of 200-500 rpm for 8-24 hours to obtain a suspension A;

[0023] 4. Dry the suspension A obtained in step 3 to obtain powder A, and then put the powder A into a tube furnace and keep it at a temperature of 800-1000°C for 3-6 hours to obtain pre-calcined powder;

[0024]...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the heating temperature in step 1 is 150-250° C., and the heating time is 0.5-2 h; other aspects are the same as Embodiment 1.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying temperature of suspension A in step 4 is 60-120° C.; the others are the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com