Method for preparing niobate photocatalyst

A photocatalyst, niobate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor photocatalyst adsorption, low photodegradation efficiency, etc. problem, to achieve the effect of narrow particle size distribution, high photodegradation efficiency and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: the preparation method of the niobate photocatalyst of this embodiment is realized according to the following steps: 1. Weigh 0.20~0.30g of niobium pentoxide and 3.0~3.5g of potassium hydroxide and dissolve them in 5~8mL of Ionized water, then placed on a magnetic stirrer and stirred for 30-60 minutes to obtain the mixture; 2. Add the mixture to a high-pressure reactor with a polytetrafluoroethylene liner, seal it and then under the condition of a temperature of 220-240°C, Heat treatment for 12 to 24 hours, and naturally cool to room temperature to obtain the niobate photocatalyst precursor; 3. Filter and wash the niobate photocatalyst precursor for 3 to 5 times, and then dry it at a temperature of 80 to 100°C After 5-10 hours, the niobate photocatalyst is obtained; the amount of the mixture added in the second step is 60%-80% of the volume of the polytetrafluoroethylene-lined autoclave.

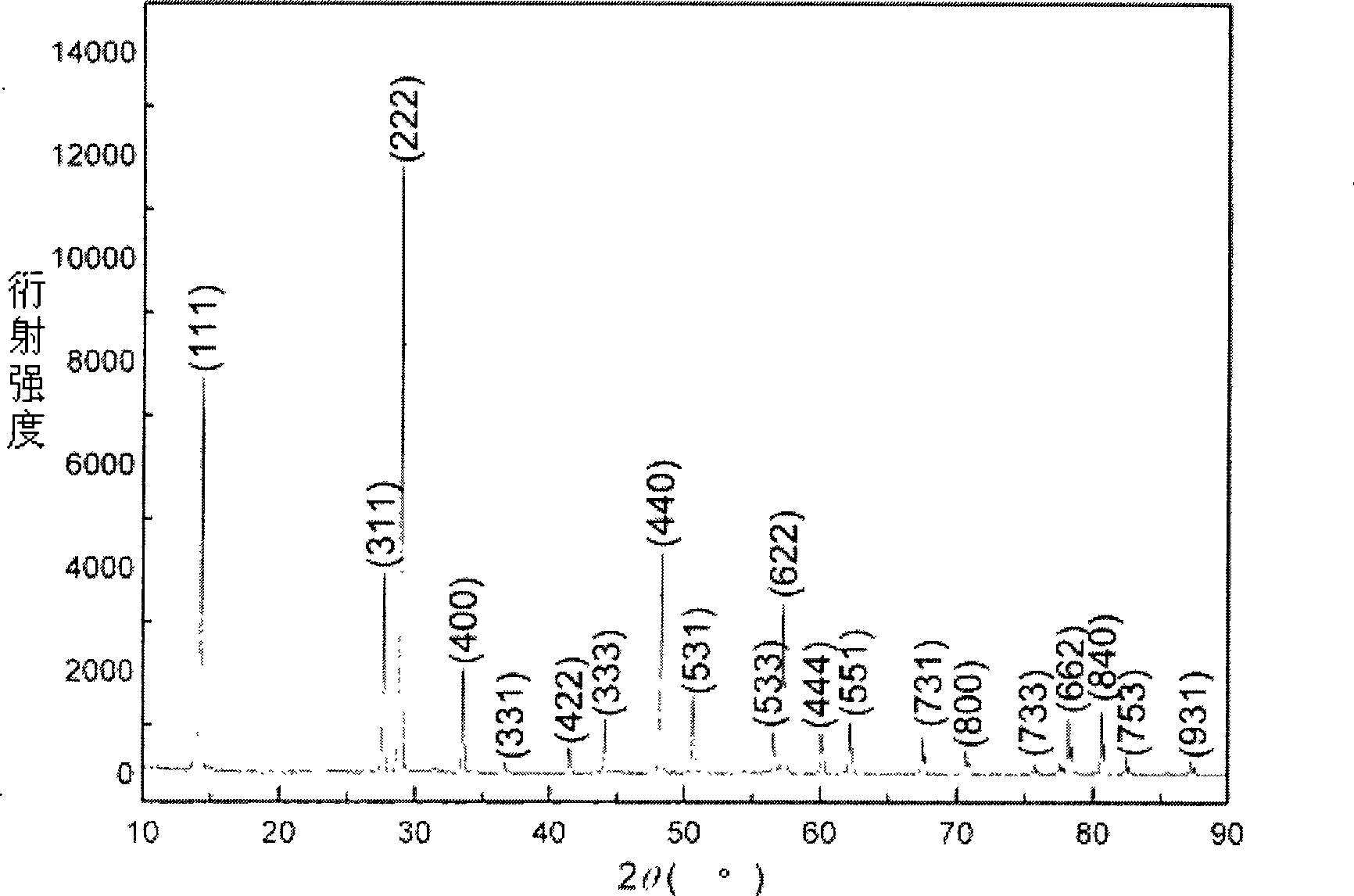

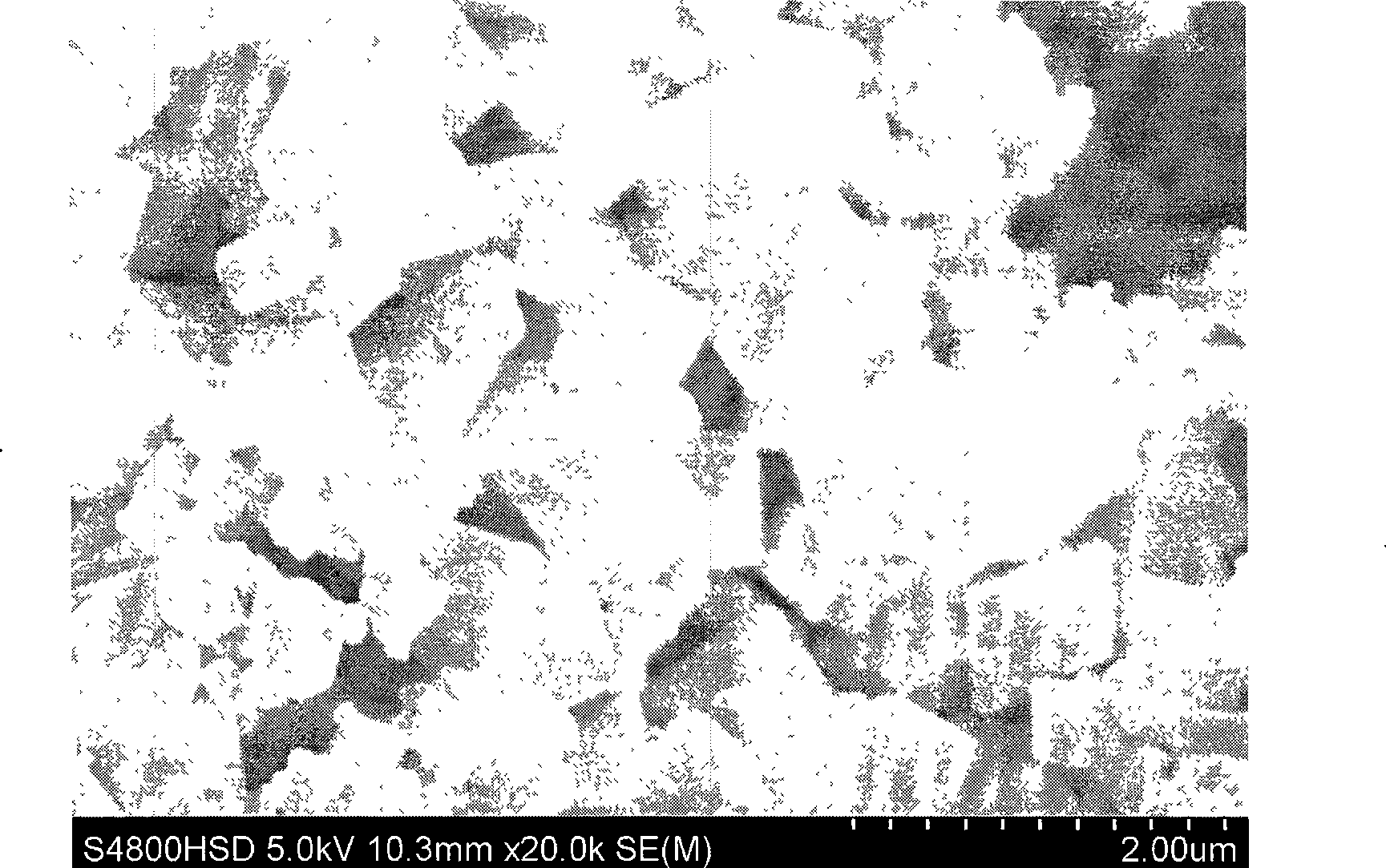

[0010] This embodiment is the first time that pyrochlore...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, 0.22-0.28 g of niobium pentoxide and 3.1-3.4 g of potassium hydroxide are weighed and dissolved in 5.5-7.5 mL of deionized water. Other steps and parameters are the same as those in Embodiment 1.

[0012] The niobium pentoxide and potassium hydroxide used in this embodiment can be purchased in the market, which greatly reduces the production cost.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 in that in step 1, 0.24-0.26 g of niobium pentoxide and 3.25-3.35 g of potassium hydroxide are weighed and dissolved in 6-7 mL of deionized water. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com