Super-stable temperature type electronic ceramic material

An electronic ceramic and stable technology, applied in the field of dielectric ceramics, can solve the problems of being unable to be used in stricter occasions, low electrical performance of barium titanate ceramics, and unsuitable for practical application, etc. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

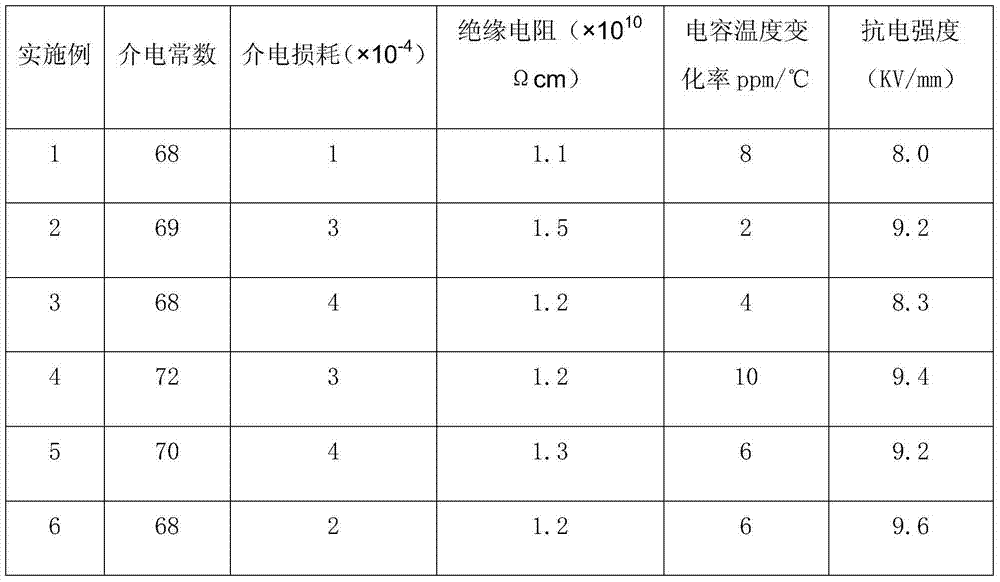

Examples

Embodiment 1

[0016] A temperature ultra-stable electronic ceramic material, mainly composed of the following raw materials in parts by weight: 25 parts of barium titanate, 8 parts of aluminum oxide, 15 parts of zirconium dioxide, 10 parts of manganese oxide, 3 parts of nickel oxide, and 2 parts of zinc oxide , 0.01 parts of gallium oxide, 10 parts of nano silicon dioxide, 1 part of magnesium oxide, 2 parts of nano boron nitride, and 0.1 part of thulium oxide.

[0017] A method for preparing a temperature ultra-stable electronic ceramic material, including the steps of mixing materials, ball milling, molding, drying, calcination to remove iron, spray granulation, etc., put the pressed ceramic material under nitrogen protection, and the initial temperature is 100 Heating in a heating furnace at ℃ for 0.5h, nitrogen flow rate: 5ml / min; then raising the temperature to 950°C for 1.5h calcination, and then rapidly raising the temperature to 1750°C for 0.5 hours under the protection of hydrogen, a...

Embodiment 2

[0019] A temperature ultra-stable electronic ceramic material, mainly composed of the following raw materials in parts by weight: 38 parts of barium titanate, 10 parts of aluminum oxide, 25 parts of zirconium dioxide, 20 parts of manganese oxide, 9 parts of nickel oxide, and 8 parts of zinc oxide , 0.1 parts of gallium oxide, 18 parts of nano silicon dioxide, 5 parts of magnesium oxide, 8 parts of nano boron nitride, and 1.5 parts of thulium oxide.

[0020] A method for preparing a temperature ultra-stable electronic ceramic material, including the steps of mixing materials, ball milling, molding, drying, calcination to remove iron, and spray granulation. The pressed ceramic material is placed under nitrogen protection, and the initial temperature is 200 ° C. Heating in a heating furnace for 1.0h, nitrogen flow rate: 40ml / min; after that, the temperature was raised to 1000°C for 2.5h, and then the temperature was rapidly raised to 1900°C under the protection of hydrogen for 1.0...

Embodiment 3

[0022] A temperature ultra-stable electronic ceramic material, mainly composed of the following raw materials in parts by weight: 28 parts of barium titanate, 8 parts of aluminum oxide, 18 parts of zirconium dioxide, 12 parts of manganese oxide, 5 parts of nickel oxide, and 3.5 parts of zinc oxide , 0.04 parts of gallium oxide, 12 parts of nano silicon dioxide, 2 parts of magnesium oxide, 3 parts of nano boron nitride, and 0.5 parts of thulium oxide.

[0023] A method for preparing a temperature ultra-stable electronic ceramic material, comprising the steps of mixing materials, ball milling, molding, drying, calcining to remove iron, spraying granulation, etc., characterized in that: the pressed ceramic material is placed under nitrogen protection, Heating in a heating furnace with an initial temperature of 250°C for 0.6h, nitrogen flow rate: 10ml / min; then raising the temperature to 990°C for 2.2h calcination, and then rapidly raising the temperature to 18550°C under the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com