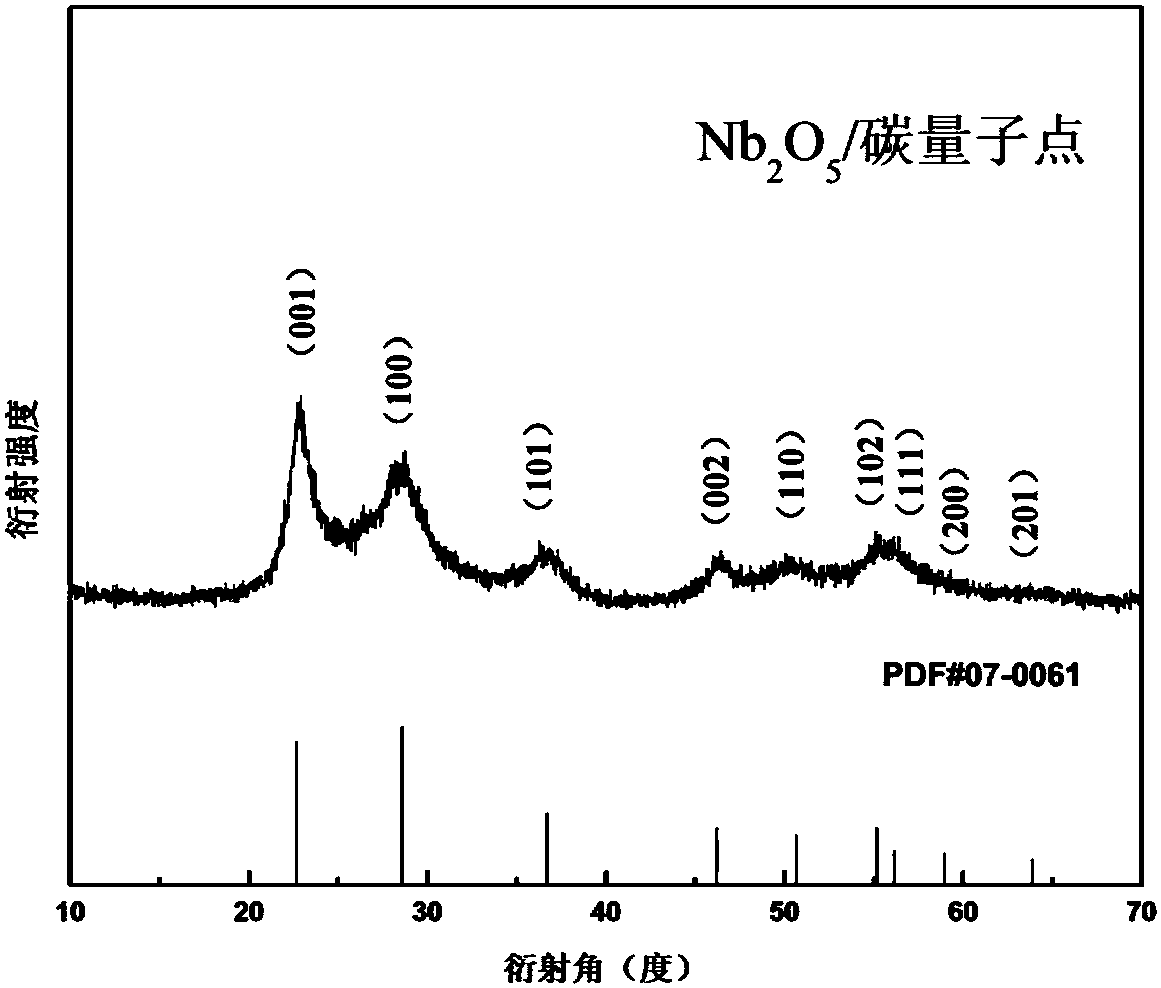

Niobium pentoxide/carbon double-quantum-dot nanometer composite material, method for preparing same and application of niobium pentoxide/carbon double-quantum-dot nanometer composite material

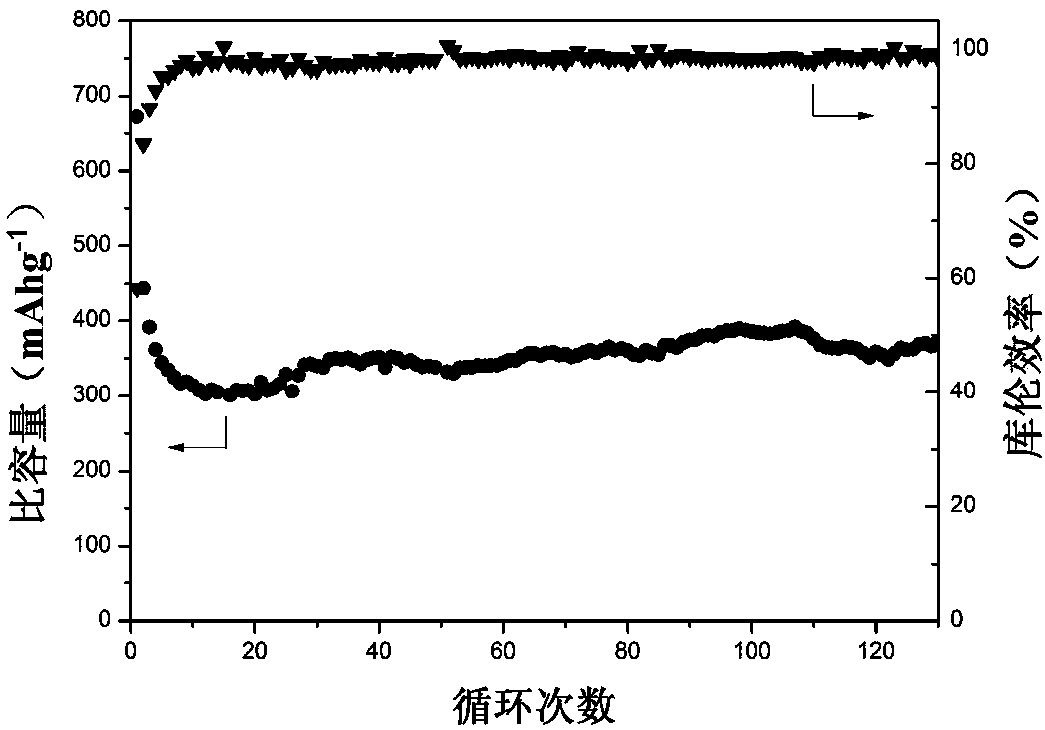

A nanocomposite material, niobium pentoxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of poor actual capacity and cycle stability of materials, poor conductivity of materials, and easy structure damage. Destruction and other problems, to achieve the effect of controllable product morphology, short diffusion distance, and favorable infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Take 3mmol of sucrose and dissolve it in 30ml of deionized water, and then perform ultrasonic operation to obtain a uniform clear and transparent solution, then put it in a furnace at 160°C for 3h. After the completion of the hydrothermal treatment, the obtained sample was ultrasonicated for 6 hours to obtain a uniform and stable tan solution, that is, a 1.2 mol / L carbon quantum dot solution.

[0045] Add niobium hydroxide and oxalic acid into 5 mL of deionized water at a molar ratio of 1:4.5, with a niobium ion concentration of 0.3 mol / L, and stir at 80°C until clear. Add 0.5 g of polyvinylpyrrolidone with an average molecular weight of 58,000 into the aforementioned solution, and stir until clear. Add 10mL of the previously prepared carbon quantum dot solution to the previously prepared solution, then add 15ml of isopropanol into the prepared mixed solution, mix well and transfer to a 50mL hydrothermal reaction kettle, and heat 12h. The resulting product was centrifu...

Embodiment 2

[0050] Take 1.5mmol of sucrose and dissolve it in 30ml of deionized water, and then perform ultrasonic operation to obtain a uniform clear and transparent solution, then put it in a furnace at 160°C for 3 hours. After the completion of the hydrothermal treatment, the obtained sample was ultrasonicated for 6 hours to obtain a uniform and stable tan solution, that is, a 0.6 mol / L carbon quantum dot solution.

[0051] Add niobium hydroxide and oxalic acid into 10 mL of deionized water at a molar ratio of 1:9, with a niobium ion concentration of 0.15 mol / L, and stir at 80°C until clear. Add 0.5 g of polyvinylpyrrolidone with an average molecular weight of 1,300,000 into the aforementioned solution, and stir until clear. Add 10mL of the previously prepared carbon quantum dot solution to the previously prepared solution, then add 10ml of isopropanol into the prepared mixed solution, mix well, transfer to a 50mL hydrothermal reaction kettle, and heat at 190°C for 6h . The resulting...

Embodiment 3

[0053] Take 2mmol of sucrose and dissolve it in 30ml of deionized water, and then perform ultrasonic operation to obtain a uniform clear and transparent solution, then put it in a furnace at 160°C for 3h. After the completion of the hydrothermal treatment, the obtained sample was ultrasonicated for 6 hours to obtain a uniform and stable tan solution, that is, a 0.8 mol / L carbon quantum dot solution.

[0054] Add niobium hydroxide and oxalic acid into 5 mL of deionized water at a molar ratio of 1:1, the concentration of niobium ions is 0.3 mol / L, and stir at 80°C until clear. Add 0.5 g of polyvinylpyrrolidone with an average molecular weight of 48,000 to the aforementioned solution, and stir until clear. Add 10mL of 0.5mol / L carbon quantum dot solution to the prepared aforementioned solution, then add 10ml of ethylene glycol into the prepared mixed solution, mix well and transfer to a 50mL hydrothermal reaction kettle, and water Heat for 10 hours. The resulting product was ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com