Flower-like niobium pentoxide material and preparation method thereof

A technology of niobium pentoxide and niobium pentachloride, applied in chemical instruments and methods, inorganic chemistry, niobium compounds, etc., to achieve the effects of good dispersion, strong controllability of reaction conditions, uniform and regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1). Dissolve niobium pentachloride in deionized water under stirring conditions, where the concentration of niobium ions is 0.55 mol / L;

[0031] Step 2). Add hydrofluoric acid to the above aqueous solution of niobium pentachloride, wherein the molar ratio of niobium pentachloride to hydrofluoric acid is 1:0.5, and continue to stir for 16 hours;

[0032] Step 3). Transfer the solution obtained in step 2) to a high-pressure stainless steel reactor, place it in a constant temperature drying oven, and heat and react at 180°C for 24 hours;

[0033] Step 4) Centrifuge the reaction precipitate obtained in step 3), wash it with ethanol and deionized water several times, and then dry it in a vacuum drying oven at a temperature of 80°C;

[0034] Step 5). Place the powder obtained in step 4) in a tube furnace and calcine at 600°C for 1 hour to obtain flower-like Nb 2 O 5 material.

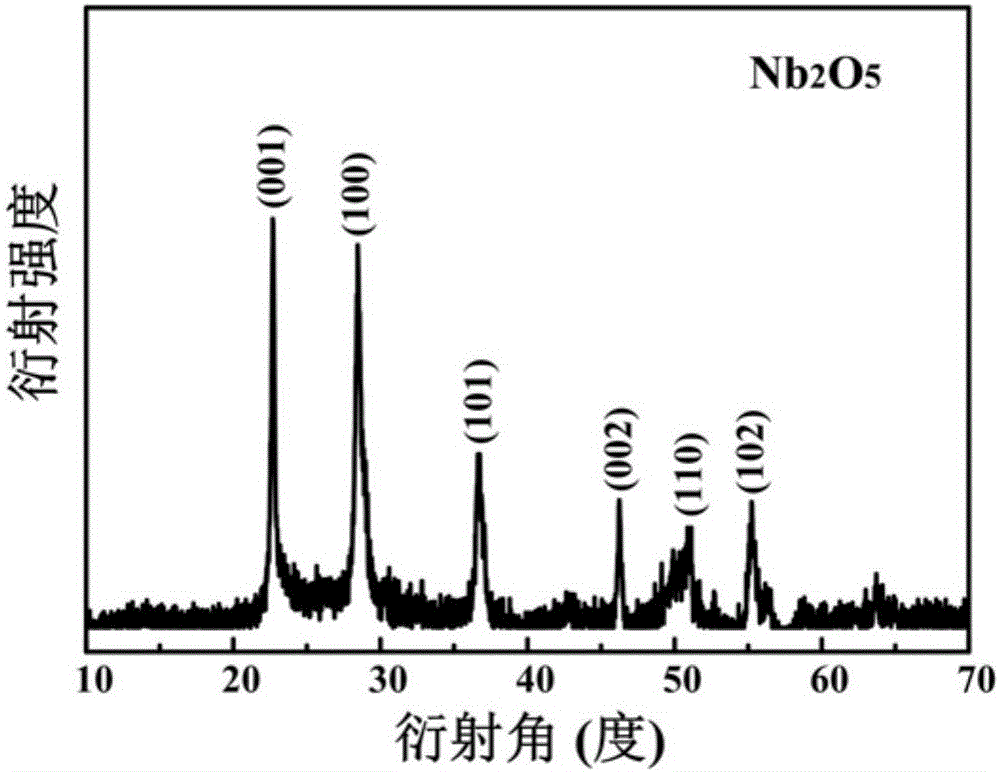

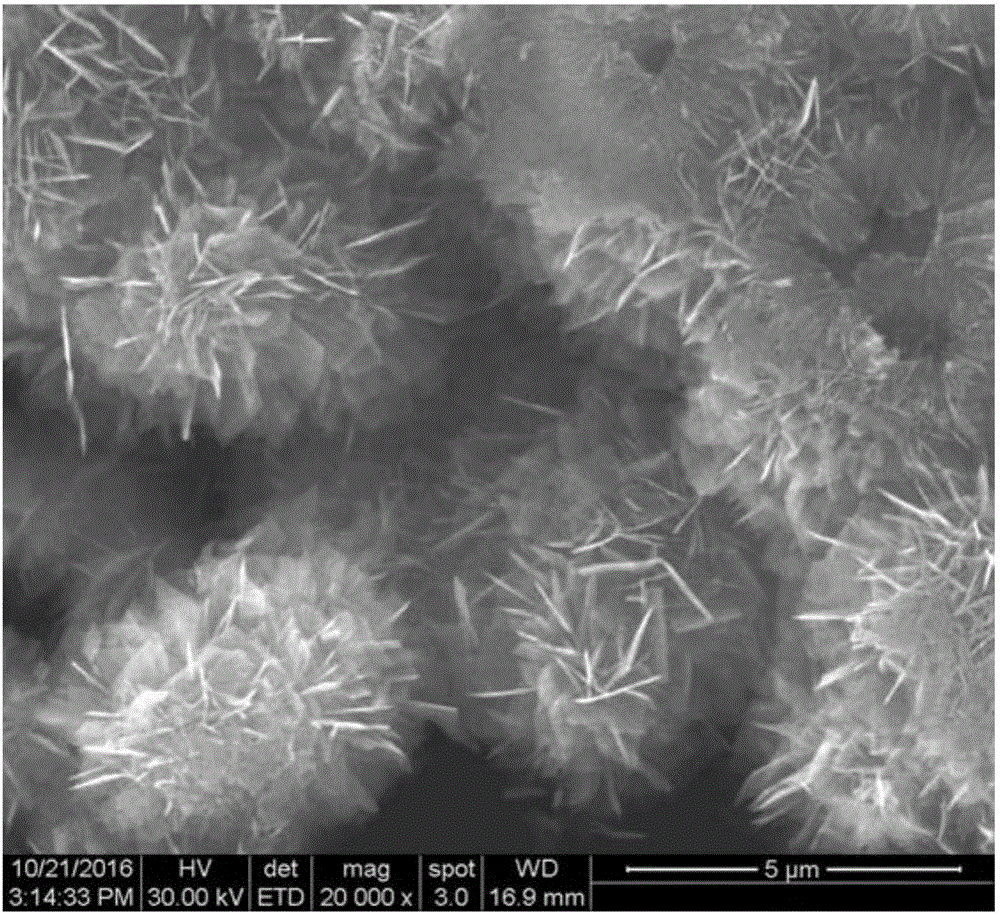

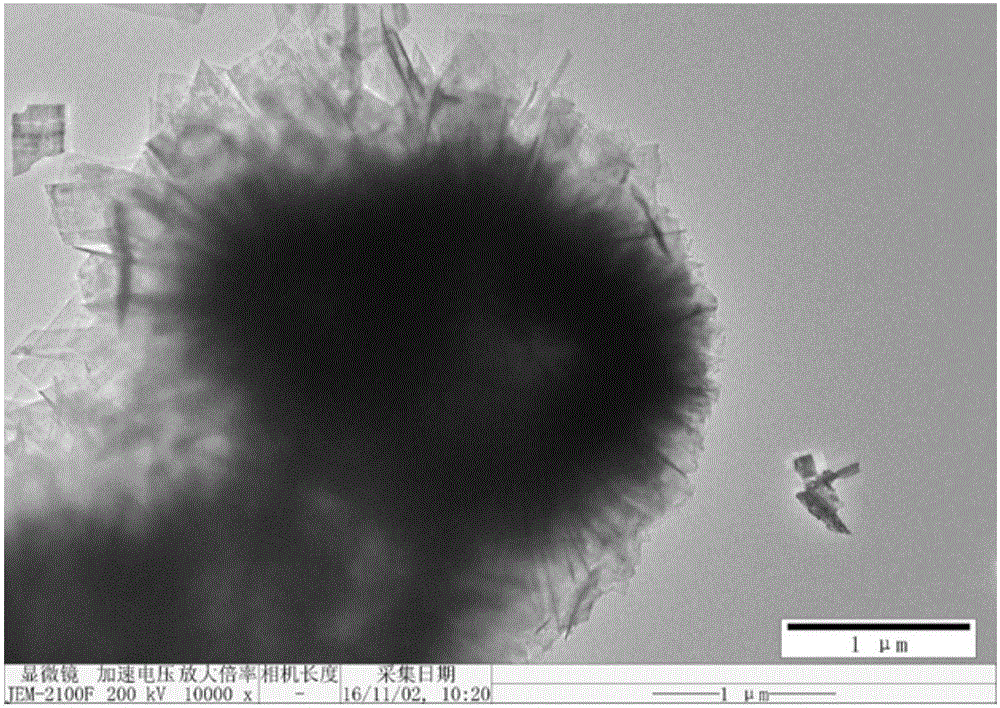

[0035] Such as figure 1 As shown, the diffraction peak of the sample and Nb 2 O 5 The standard diffracti...

Embodiment 2

[0037] Step 1). Dissolve niobium pentachloride in deionized water under stirring conditions, where the concentration of niobium ions is 0.055 mol / L;

[0038] Step 2). Add hydrofluoric acid to the above aqueous solution, wherein the molar ratio of niobium pentachloride to hydrofluoric acid is 1:0.2, and continue to stir for 24 hours;

[0039] Step 3). Transfer the solution obtained in step 2) to a high-pressure stainless steel reactor, place it in a constant temperature drying oven, and heat and react at 178°C for 15 hours;

[0040] Step 4) Centrifuge the reaction precipitate obtained in step 3), wash it with ethanol and deionized water several times, and then dry it in a vacuum drying oven at a temperature of 110°C;

[0041] Step 5). Place the powder obtained in step 4) in a tube furnace and calcinate at 600°C for 1.5 hours to obtain flower-like Nb 2 O 5 material.

Embodiment 3

[0043] Step 1). Dissolve niobium pentachloride in deionized water under stirring conditions, where the concentration of niobium ions is 0.45 mol / L;

[0044] Step 2). Add hydrofluoric acid to the above aqueous solution, wherein the molar ratio of niobium pentachloride to hydrofluoric acid is 1:0.6, and continue to stir for 16 hours;

[0045] Step 3). Transfer the solution obtained in step 2) to a high-pressure stainless steel reactor, place it in a constant temperature drying oven, and heat and react at 185°C for 1 hour;

[0046] Step 4) Centrifuge the reaction precipitate obtained in step 3), wash it with ethanol and deionized water several times, and then dry it in a vacuum drying oven at a temperature of 100°C;

[0047] Step 5). Place the powder obtained in step 4) in a tube furnace and calcinate at 700°C for 0.5 hours to obtain flower-like Nb 2 O 5 material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com