X9R ceramic capacitor dielectric material and preparation method thereof

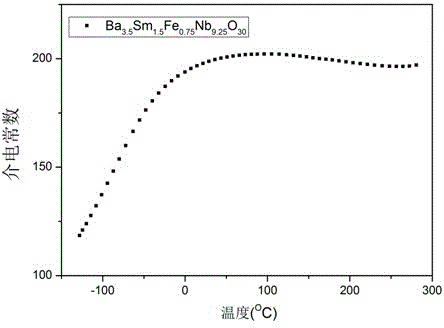

A technology for ceramic capacitors and dielectric materials, applied in the field of X9R type ceramic capacitor dielectric materials and their preparation, can solve problems such as inability to provide temperature dielectric properties, and achieve good industrialization prospects, simple process, and good temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

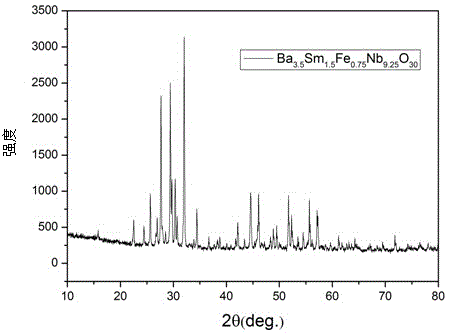

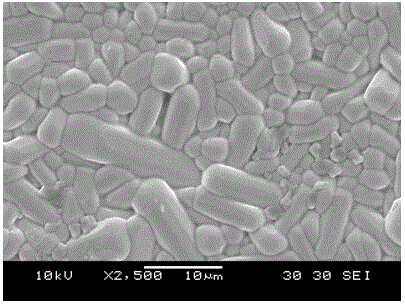

[0016] BaCO with a purity of 99.99% 3 、Sm 2 o 3 , Nb 2 o 5 and Fe 2 o 3 The raw material is Ba according to the stoichiometric ratio 3.5 SM 1.5 Fe 0.75 Nb 9.25 o 30 The ingredients are put into the ball mill tank; the zirconia ball and the nylon tank are selected; the quality of the added raw material is 8% of the mass of the ball; the mixing ball milling time is 48 hours, the rotating speed is 350 rpm, and the ball milling medium is absolute ethanol; the obtained The product was dried in an oven at 100°C for 5 hours, and pre-sintered at 1200°C for 4 hours at a heating rate of 5°C / min; the pre-sintered powder was taken out and ground, and then ball milled with absolute ethanol as the ball milling medium for 48 hours. Mix evenly for 1 hour, dry at 100°C for 5 hours, grind into powder, use 5% polyvinyl alcohol aqueous solution as a binder to granulate, pass through a 60-mesh sieve, and press it into a diameter of 100MPa 12mm, thickness of 1mm disc-shaped green body, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com