Niobium pentaoxide doped cerium dioxide preparation method and product and application thereof

A technology of niobium pentoxide and cerium dioxide, which is applied in the field of material preparation and environmental protection, can solve the problems of low solubility of niobium salt, no VOCs application, uneven particle distribution, etc., and achieve no precipitant, simple operation and simple raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

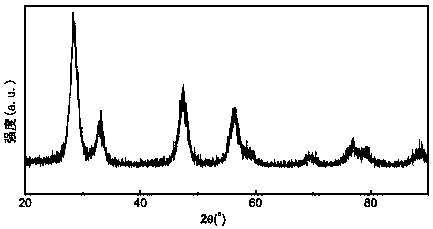

Embodiment 1

[0031] Weigh 7.5688g of cerium nitrate hexahydrate and 3.6605g of citric acid in a 20 mL beaker, add 5 mL of deionized water, stir and dissolve to obtain solution A; weigh 0.1214 g of niobium oxalate in a 20 mL beaker, add 5 mL of Deionized water, stir and dissolve to obtain solution B; weigh 1g of polyvinyl alcohol and place it in a 50 mL beaker, add 30 mL of deionized water, heat and stir to dissolve to obtain solution C, the heating temperature is 60-80°C; under stirring, dissolve 10ml Left and right solution C was dropped into solution B drop by drop, and continued to stir for 0.5-1h to obtain sol D; under strong stirring, drop sol D into solution A drop by drop, and continued to stir for 10min-30min to obtain gel E; The fourth step is to place the gel E in a muffle furnace with a set temperature of 400°C for combustion. After the combustion is complete, it is roasted for 2 hours to obtain the Nb 2 o 5 Doped CeO 2 The carrier material (mass ratio of cerium oxide and niob...

Embodiment 2

[0033]Weigh 7.3417g of cerium nitrate hexahydrate and 3.553g of citric acid in a 20 mL beaker, add 5 mL of deionized water, stir and dissolve to obtain solution A; weigh 0.3642 g of niobium oxalate in a 20 mL beaker, add 5 mL of Deionized water, stir and dissolve to obtain solution B; weigh 1g of polyvinyl alcohol and place it in a 50 mL beaker, add 30 mL of deionized water, heat and stir to dissolve to obtain solution C, the heating temperature is 60-80°C; under stirring, dissolve 10ml Left and right solution C was dropped into solution B drop by drop, and continued to stir for 0.5-1h to obtain sol D; under strong stirring, drop sol D into solution A drop by drop, and continued to stir for 10min-30min to obtain gel E; The fourth step is to place the gel E in a muffle furnace with a set temperature of 400°C for combustion. After the combustion is complete, it is roasted for 2 hours to obtain the Nb 2 o 5 Doped CeO 2 The carrier material (mass ratio of cerium oxide and niobiu...

Embodiment 3

[0035] Weigh 7.5688g of cerium nitrate hexahydrate and 3.6605g of citric acid in a 20 mL beaker, add 5 mL of deionized water, stir and dissolve to obtain solution A; weigh 0.1214 g of niobium oxalate in a 20 mL beaker, add 5 mL of Deionized water, stir and dissolve to obtain solution B; weigh 1g of polyvinyl alcohol and place it in a 50 mL beaker, add 30 mL of deionized water, heat and stir to dissolve to obtain solution C, the heating temperature is 60-80°C; under stirring, dissolve 10ml Left and right solution C was dropped into solution B drop by drop, and continued to stir for 0.5-1h to obtain sol D; under strong stirring, drop sol D into solution A drop by drop, and continued to stir for 10min-30min to obtain gel E; The fourth step is to place the gel E in a muffle furnace with a set temperature of 400°C for combustion. After the combustion is complete, it is roasted for 3 hours to obtain the Nb 2 o 5 Doped CeO 2 The carrier material (mass ratio of cerium oxide and niob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com