Method for separating tantalum and niobium

A technology of ammonium niobium oxalate and solution, which is applied in chemical instruments and methods, niobium compounds, tantalum compounds, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

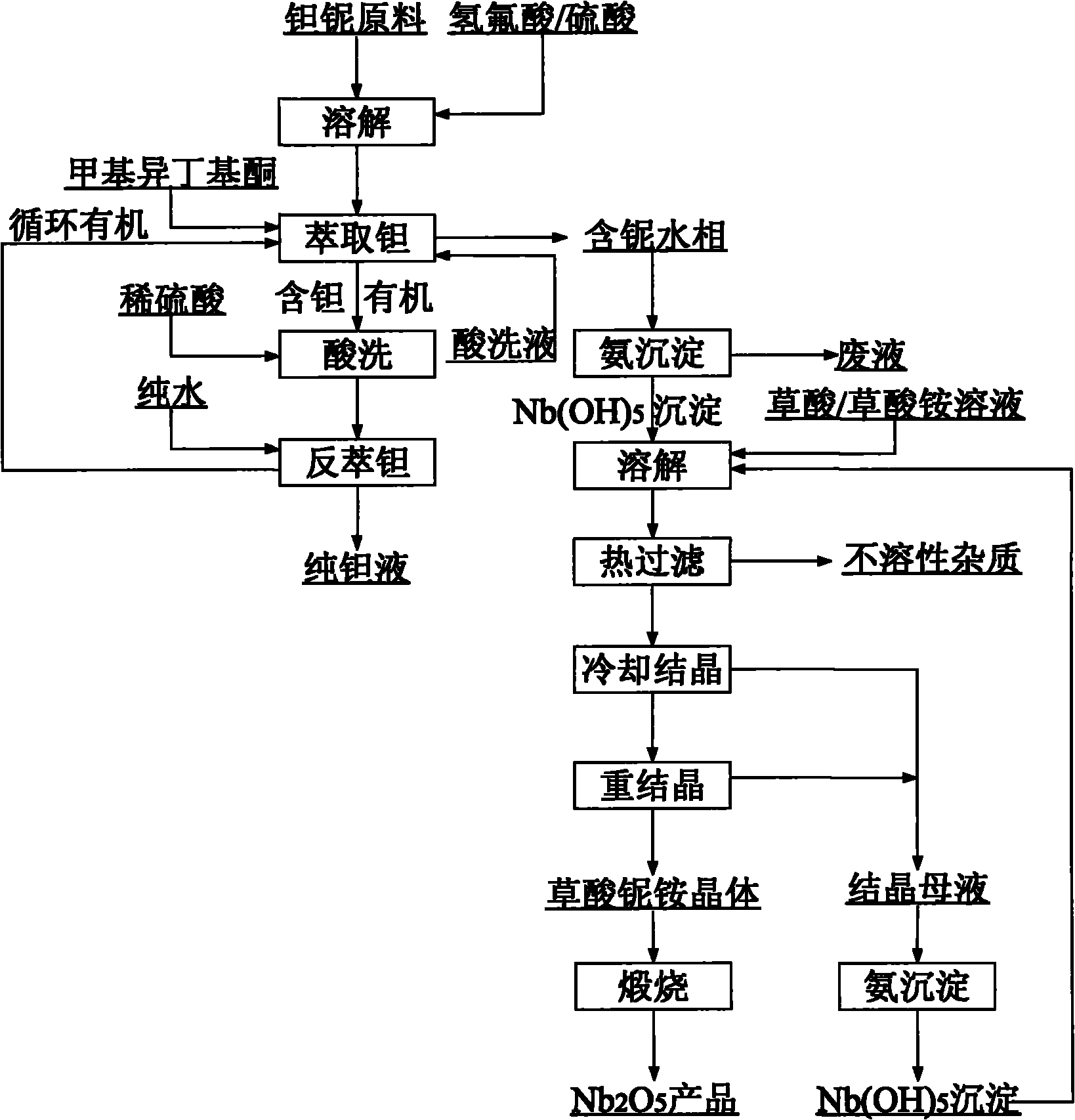

Image

Examples

Embodiment 1

[0013] The raw materials containing tantalum and niobium are added into the hydrofluoric acid solution for dissolution to obtain a solution containing tantalum and niobium-fluorine complexes, and the concentration of hydrofluoric acid in the solution is controlled to be 4mol / L. The tantalum in the obtained solution containing tantalum and niobium-fluorine complex is extracted with methyl isobutyl ketone to obtain an organic phase containing tantalum and an aqueous phase containing niobium. The volume ratio of methyl isobutyl ketone used in the extraction process to the solution containing tantalum and niobium-fluorine complexes is 10:1, and the extraction temperature is 20°C. Wash the obtained tantalum-containing organic phase with 1 mol / L dilute sulfuric acid, and control the volume ratio of the dilute sulfuric acid to the tantalum-containing organic phase to be 1:1 during the washing process. The wash solution is returned to the extraction step. The washed tantalum-containi...

Embodiment 2

[0017] The raw materials containing tantalum and niobium are added into the hydrofluoric acid / sulfuric acid mixed solution to dissolve to obtain a solution containing tantalum and niobium-fluorine complex, and the concentration of hydrofluoric acid in the solution is controlled to be 0mol / L. The tantalum in the obtained solution containing tantalum and niobium-fluorine complex is extracted with methyl isobutyl ketone to obtain an organic phase containing tantalum and an aqueous phase containing niobium. The volume ratio of methyl isobutyl ketone used in the extraction process to the solution containing tantalum and niobium-fluorine complexes is 1:1, and the extraction temperature is 90°C. Wash the obtained tantalum-containing organic phase with 5 mol / L dilute sulfuric acid, and control the volume ratio of the dilute sulfuric acid to the tantalum-containing organic phase to be 5:1 during the washing process. The wash solution is returned to the extraction step. The washed tant...

Embodiment 3

[0021] The raw materials containing tantalum and niobium are added into the hydrofluoric acid / sulfuric acid mixed solution to dissolve to obtain a solution containing tantalum and niobium-fluorine complex, and the concentration of hydrofluoric acid in the solution is controlled to be 2mol / L. The tantalum in the obtained solution containing tantalum and niobium-fluorine complex is extracted with methyl isobutyl ketone to obtain an organic phase containing tantalum and an aqueous phase containing niobium. The volume ratio of methyl isobutyl ketone used in the extraction process to the solution containing tantalum and niobium-fluorine complexes is 3:1, and the extraction temperature is 60°C. The obtained tantalum-containing organic phase was washed with 3 mol / L dilute sulfuric acid, and the volume ratio of the dilute sulfuric acid to the tantalum-containing organic phase was controlled to be 3:1 during the washing process. The wash solution is returned to the extraction step. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com