Method for synthesizing nano potassium tantalate niobate powder

A technology of potassium and sodium tantalum niobate and powder is applied in the field of ultrasonic-assisted hydrothermal synthesis of nanometer potassium and sodium tantalum niobate (O3) piezoelectric ceramic powder, and can solve the problem of inability to synthesize potassium and sodium tantalum niobate nanometer powder. , to achieve good commercial value, environmental friendliness, and improved electromechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

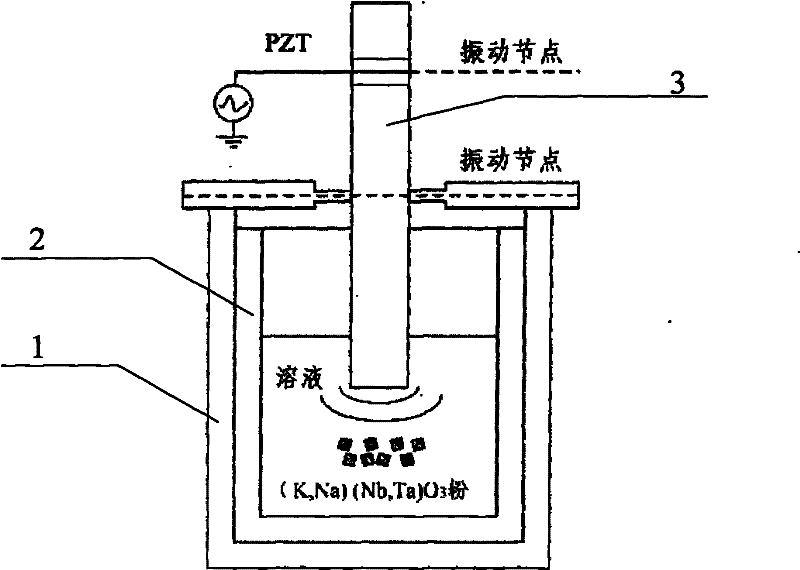

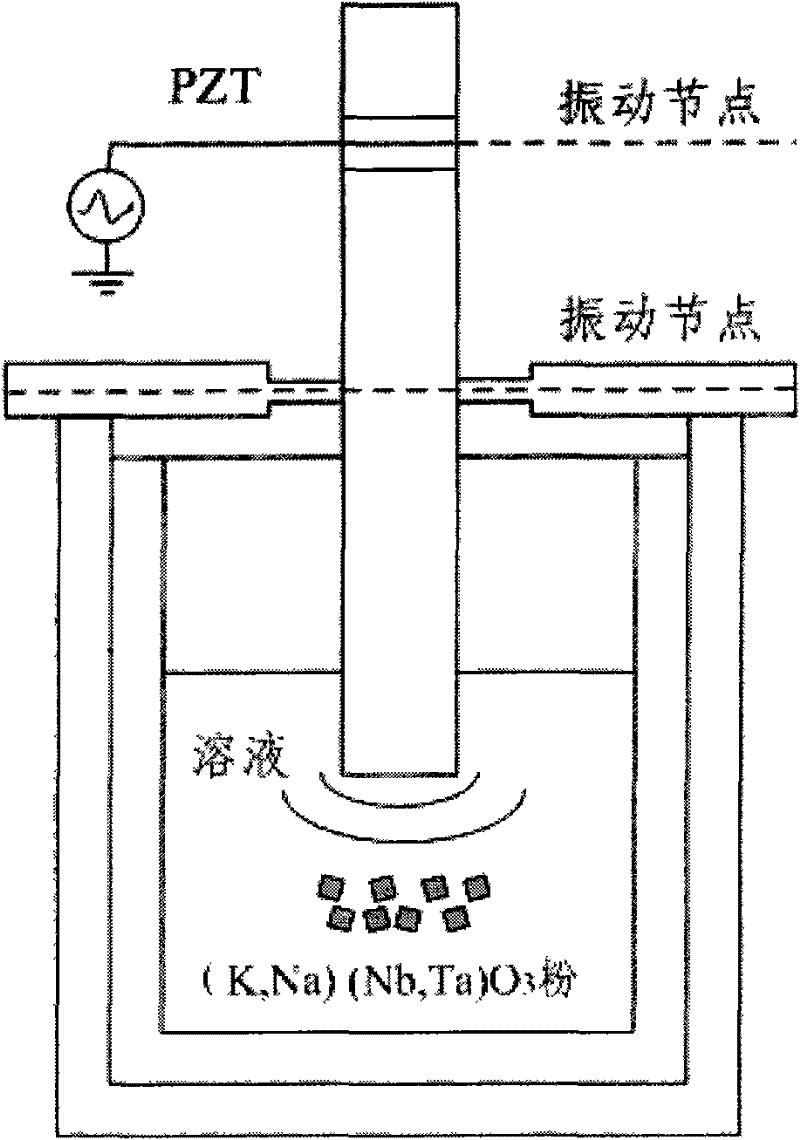

[0019] First, according to the molar ratio of sodium hydroxide and potassium hydroxide: 1:9, concentration: 6mol / L, prepare 800ml of lye, and put it into figure 1 In the ultrasonic-assisted hydrothermal equipment shown;

[0020] Then according to tantalum pentoxide and niobium pentoxide molar ratio 1: 10, be 1: 10 with the mol ratio of total amount and lye, add in the lye of step up and be made up of niobium pentoxide and tantalum pentoxide solid oxide;

[0021] The power of ultrasonic-assisted hydrothermal equipment is 20KW, the reaction temperature is 120°C, and the holding time is 4 hours. After the reaction is completed, take it out after the furnace temperature drops to room temperature, filter, centrifuge, and wash it several times, then place it in a blast drying oven at a temperature of 80°C, and dry for 6 hours to obtain potassium sodium tantalum niobate nanopowder.

[0022] result:

[0023] Potassium sodium tantalum niobate nano powder particle size d 50 = 75nm. ...

Embodiment 2

[0025] First, according to the molar ratio of sodium hydroxide and potassium hydroxide: 1:9, concentration: 6mol / L, prepare 800ml of lye, and put it into figure 1 Ultrasound-assisted hydrothermal equipment (as shown);

[0026] Then according to tantalum pentoxide and niobium pentoxide molar ratio 1: 10, be 1: 10 with the mol ratio of total amount and lye, add in the lye of step up and be made up of niobium pentoxide and tantalum pentoxide Peripheral oxides;

[0027] The power of ultrasonic-assisted hydrothermal equipment is 20KW, the reaction temperature is 160°C, and the holding time is 2 hours. After the reaction is completed, take it out after the furnace temperature drops to room temperature, filter, centrifuge, and wash it several times, then place it in a blast drying oven at a temperature of 80°C, and dry for 6 hours to obtain potassium sodium tantalum niobate nanopowder.

[0028] The result is:

[0029] Potassium sodium tantalum niobate nano powder particle size d ...

Embodiment 3

[0031] First according to sodium hydroxide and potassium hydroxide molar ratio: 3: 7, concentration: 10mol / L, prepare lye 800ml, and pack into ultrasonic auxiliary hydrothermal equipment (such as figure 1 shown);

[0032] Then according to tantalum pentoxide and niobium pentoxide molar ratio 1: 10, be 1: 10 with the mol ratio of total amount and lye, add in the lye of step up and be made up of niobium pentoxide and tantalum pentoxide solid oxide;

[0033] The power of ultrasonic-assisted hydrothermal equipment is 20KW, the reaction temperature is 120°C, and the holding time is 4 hours. After the reaction is completed, take it out after the furnace temperature drops to room temperature, filter, centrifuge, and wash it several times, then place it in a blast drying oven at a temperature of 80°C, and dry for 6 hours to obtain potassium sodium tantalum niobate nanopowder.

[0034] The result is:

[0035] Potassium sodium tantalum niobate nano powder particle size d 50 = 50nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com