Fly ash-based high-sulfur-fixation coal binder as well as preparation method and application thereof

The technology of fly ash and binder is applied in the field of high-sulfur briquette binder and its preparation, which can solve the problem of insufficient sulfur-fixing performance, and achieve the effects of increasing market value, reducing environmental pollution and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

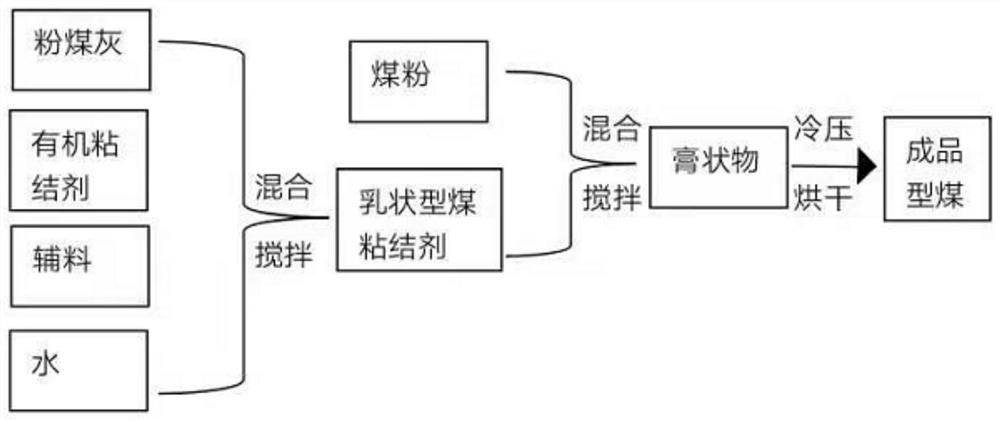

[0021] Such as figure 1 Shown, the present invention provides a kind of preparation method based on fly ash-based high-sulfur briquette binder, concrete steps are as follows:

[0022] First, take 100g of fly ash, add 40-80ml of water, then add 100-400g of sodium humate, asphalt, polyvinyl alcohol, starch, wood chips, etc. as an organic binder, and the auxiliary material is 5-25g of calcium oxide , fully mixed and stirred to obtain a milky fly ash-based high-sulfur briquette binder.

[0023] When the fly ash briquette binder obtained in the present invention is used to prepare briquettes, the binder and pulverized coal are fully mixed in a mass ratio of 1: (2-10) to form a viscous paste, which is passed through the briquette The mold is mechanically pressed and formed, usually at a pressure of 5-15T, and pressed for 5-15 minutes. Then dry it in an oven at 30-100°C for 5-30 hours, and then the molded coal with good mechanical strength and sulfur-fixing performance can be produ...

Embodiment 1

[0025] Add 100g of fly ash to 40ml of water, then add 400g of sodium humate and 10g of calcium oxide, fully stir and mix to form a milky substance, that is, a high-sulfur briquette binder based on fly ash. Mix the prepared binder with 1200g of coal powder, that is, the ratio of binder to coal powder is 1:2.2 to form a viscous paste. Put the pasty material into the briquette mold, press it under 5T pressure for 5 minutes, shape it, take it out and bake it in an oven at 50 degrees for 10 hours, and then you can get a briquette with good mechanical strength and sulfur-fixing performance.

[0026] According to MT / T 748 Determination of cold compressive strength of industrial briquettes, GB / T31861-2015 clean fuel briquettes for industrial kilns; GB / T 214 Determination of total sulfur in coal for wet pressure, dry pressure Strength and sulfur-fixing efficiency; actual tests show that the wet compressive strength of briquettes is 680N, the dry compressive strength reaches 400N, and t...

Embodiment 2

[0028] Add 100g of fly ash to 80ml of water, then add 100g of polyvinyl alcohol and 5g of calcium oxide, stir and mix thoroughly to form a milky substance, that is, a high-solid-sulfur briquette binder based on fly ash. Mix the binder with 1000g of coal powder, that is, the ratio of binder to coal powder is 1:4 to form a viscous paste. Put the pasty material into the briquette mold, press it under 10T pressure for 15 minutes, shape it, take it out and bake it in an oven at 40°C for 24 hours, and then you can get a briquette with good mechanical strength and certain sulfur-fixing performance. Actual tests show that the wet compressive strength of coal briquettes is 810N, the dry compressive strength reaches 500N, and the sulfur fixation efficiency can reach 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com