A Coal Combustion Sulphur-fixing Agent Synergized with Red Mud and Mineral Material in Quenched and Tempered Bayer Process

A Bayer process red mud and mineral material technology, applied in fuel, solid fuel, petroleum industry and other directions, can solve the problems of easy hardening of red mud slurry, low sulfur fixation rate, waste of manganese element, etc., so as to reduce the impact on human health. Damage, sulfur fixation effect is good, burden lightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

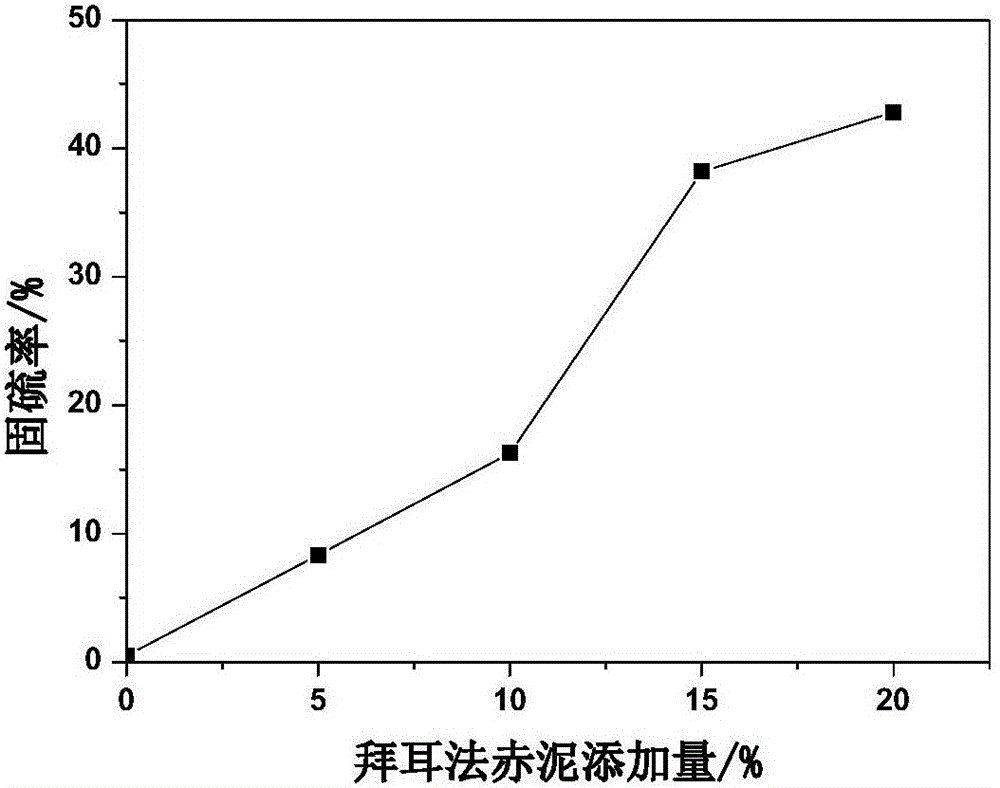

[0075] The sulfur-fixing agent of the present invention is obtained by uniformly mixing 100 g of tempered Bayer process red mud (160 mesh in particle size), 40 g of dolomite powder (160 mesh in particle size) and 1 g of vermiculite dust (160 mesh in particle size). Among them, the tempered Bayer process red mud is diluted 10 times with the industrial waste by-product salt yellow blood salt sodium mother liquor, and then the Bayer process red mud is soaked in the diluted solution, and after 24 hours, it is placed in a drying oven at a constant temperature of 80°C to dry. until the water evaporates completely.

[0076] Take 500g of coal powder and 75g of the above-mentioned sulfur-fixing agent, mix the sulfur-fixing agent and coal powder evenly, and burn the coal at 950°C. By analyzing the sulfur content of the sulfur-fixing ash, the sulfur-fixing rate is calculated to be 71.2%.

Embodiment 2

[0078]The sulfur-fixing agent of the present invention is prepared by uniformly mixing 100 g of tempered Bayer process red mud (170 mesh in particle size), 40 g of dolomite powder (170 mesh in particle size) and 3 g of vermiculite dust (160 mesh in particle size). Among them, the tempered Bayer process red mud is diluted 10 times with the industrial waste by-product salt yellow blood salt sodium mother liquor, and then the Bayer process red mud is soaked in the diluted solution, and after 24 hours, it is placed in a drying oven at a constant temperature of 80°C to dry. until the water evaporates completely.

[0079] Take 500g of coal powder and 100g of the above-mentioned sulfur-fixing agent, mix the sulfur-fixing agent and coal powder evenly, and burn the coal at 950°C. By analyzing the sulfur content of the sulfur-fixing ash, the sulfur-fixing rate is calculated to be 87.80%.

Embodiment 3

[0081] The sulfur-fixing agent of the present invention is obtained by uniformly mixing 100 g of tempered Bayer process red mud (180 mesh in particle size), 40 g of dolomite powder (170 mesh in particle size) and 3 g of vermiculite dust (160 mesh in particle size). Among them, the tempered Bayer process red mud is diluted 10 times with the industrial waste by-product salt yellow blood salt sodium mother liquor, and then the Bayer process red mud is soaked in the diluted solution, and after 24 hours, it is placed in a drying oven at a constant temperature of 80°C to dry. until the water evaporates completely.

[0082] Take 500g of coal powder and 125g of the above-mentioned sulfur-fixing agent, mix the sulfur-fixing agent and coal powder evenly, and burn the coal at 950°C. By analyzing the sulfur content of the sulfur-fixing ash, the sulfur-fixing rate is calculated to be 97.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com