Calcium-based potassium-magnesium-silicon composite additive for improving the high-temperature sulfur fixation effect of civil coke and its preparation method and application

A composite additive, calcium-based technology, used in coke ovens, solid fuels, fuels, etc., can solve the problems of loss of sulfur-fixing ability, sulfur-fixing rate of less than 20%, unsuitable for civil coke, etc. The effect of improving environmental quality and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

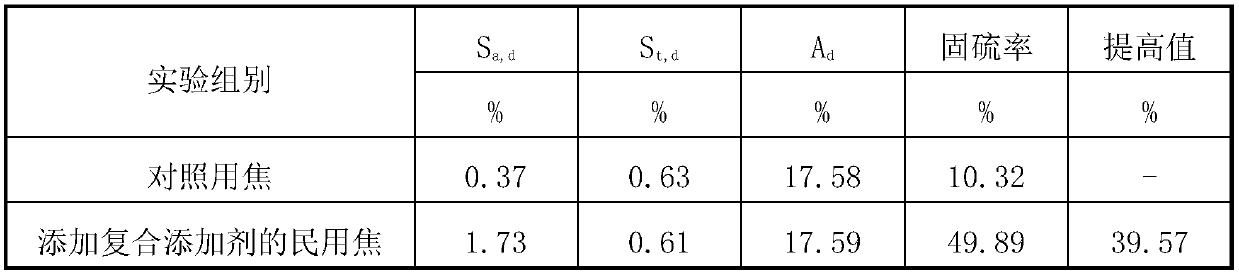

Embodiment 1

[0025] (1) Coarsely crush and finely crush the dried limestone, potassium feldspar, silicon dioxide and magnesium carbonate additive raw materials to a particle size of ≤3mm;

[0026] (2) Weigh 80kg of crushed limestone, 10kg of potassium feldspar, 10kg of silicon dioxide, and 5kg of magnesium carbonate in turn, and mix them together and stir evenly;

[0027] (3) The uniformly stirred mixture is dry-ground to make the particle size of the raw material ≤ 150 mesh (0.1mm); then calcined at 260°C for 2 hours, and cooled to room temperature, which is the calcium-based potassium-magnesium-silicon composite additive;

[0028] (4) Furnace coal is mixed with 20wt% long-flame coal, 15wt% lean coal, 30wt% 1 / 3 coking coal, 20wt% fat coal and 15wt% main coking coal; the quality index of the blended coal For: V adf 30.0%, A d 13.5%, FC d 60.6%, S t,d 0.67%; cohesion index G=74, fineness (≤3mm)=73.6%;

[0029] ⑸According to the calcium-based potassium-magnesium-silicon composite addit...

Embodiment 2

[0042] (1) Coarsely crush and finely crush the dried limestone, potassium feldspar, silicon dioxide and magnesium carbonate additive raw materials to a particle size of ≤3mm;

[0043] (2) Weigh 75kg of crushed limestone, 12.5kg of potassium feldspar, 12.5kg of silicon dioxide, and 6.3kg of magnesium carbonate in turn, and mix them together and stir evenly;

[0044] (3) The uniformly stirred mixture is dry-ground to make the particle size of the raw material ≤ 150 mesh (0.1mm); then calcined at 270°C for 1.8 hours, cooled to room temperature and packaged, which is the calcium-based potassium-magnesium-silicon composite additive;

[0045] (4) Furnace coal is blended with 30wt% weak caking coal, 40wt% long-flame coal, 20wt% gas fertilizer coal and 10wt% non-caking coal; its quality index (wt%): V adf 35.0%, A d 13.5%, FC d 56.2%, S t,d 0.67%, cohesion index G=40, fineness (≤3mm)=86.5%;

[0046] ⑸According to the calcium-based potassium-magnesium-silicon composite additive: t...

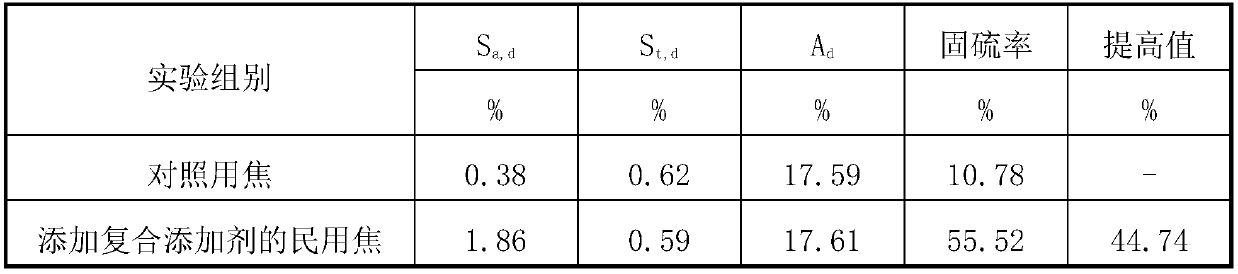

Embodiment 3

[0052] (1) Coarsely crush and finely crush the dried limestone, potassium feldspar, silicon dioxide and magnesium carbonate additive raw materials to a particle size of ≤3mm;

[0053] (2) Weigh 70kg of crushed limestone, 15kg of potassium feldspar, 15kg of silicon dioxide, and 7.5kg of magnesium carbonate in turn, and mix them together and stir evenly;

[0054] (3) The uniformly stirred mixture is dry-ground to make the particle size of the raw material ≤ 150 mesh (0.1mm); then calcined at 280°C for 1.5 hours, cooled to room temperature and packaged, which is the calcium-based potassium-magnesium-silicon composite additive;

[0055] (4) Furnace coal is mixed with 20wt% long-flame coal, 15wt% lean coal, 30wt% 1 / 3 coking coal, 20wt% fat coal and 15wt% main coking coal; the quality index of the blended coal For: V adf 30.0%, A d 13.5%, FC d 60.6%, S t,d 0.67%; cohesion index G=74, fineness (≤3mm)=73.6%;

[0056] ⑸According to the calcium-based potassium-magnesium-silicon com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com