Method for preparing coal economizing agents

A technology of coal-saving agent and surfactant, which is applied in the field of preparation of coal-saving agent, can solve the problems of large amount of addition, pollution of the environment, etc., and achieve the improvement of sulfur fixation rate, conversion rate and sulfation rate, and enhanced connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

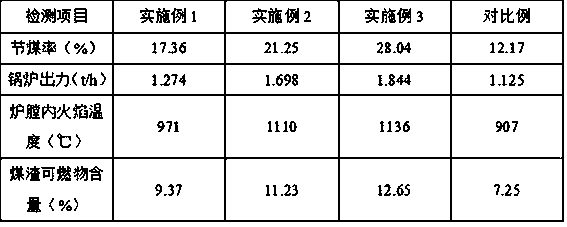

Examples

preparation example Construction

[0024] A preparation method of a coal-saving agent, the preparation method comprising the steps of:

[0025] (1) According to the mass ratio of 1:5, mix the multi-walled carbon nanotubes and chitosan solution, and ultrasonically oscillate at a temperature of 70-80°C for 3-4 hours to obtain the oscillation liquid. According to the mass ratio of 10-15:1, Mix the alcohol aqueous solution and the surfactant, and stir evenly to obtain a mixed solution;

[0026] (2) In terms of parts by weight, take 40~50 parts of mixed solution, 10~15 parts of ethanol solution, 5~6 parts of oscillating solution, and 1~2 parts of butyl titanate, and add the oscillating solution to the mixed solution for ultrasonic dispersion 1 For ~2 h, add butyl titanate and ethanol solution under stirring at 200~300r / min at a temperature of 28~32°C, let it stand for 4~5 h, filter to obtain a filter residue, and dry the filter residue at a temperature of 100~120°C for 3~ 4h, and then roasted at a temperature of 10...

Embodiment 1

[0031] Multi-walled carbon nanotubes were purchased from Beijing Deke Daojin Technology Co., Ltd.

[0032] Chitosan solution is to mix chitosan and acetic acid solution according to the mass ratio of 1:5, and stir evenly to obtain chitosan solution.

[0033] The alcohol aqueous solution is to mix ethanol and water evenly according to the mass ratio of 1:0.8 to obtain the alcohol aqueous solution.

[0034] The surfactant was cetyltrimethylammonium bromide.

[0035] Gases are nitrogen, carbon dioxide, oxygen.

[0036] The cleaning agent is cyclopentadiene.

[0037] A preparation method of a coal-saving agent, the preparation method comprising the steps of:

[0038](1) According to the mass ratio of 1:5, mix the multi-walled carbon nanotubes and chitosan solution, and ultrasonically oscillate for 3 hours at a temperature of 70°C to obtain the oscillation liquid. The agent is mixed, stirred evenly, and a mixed solution is obtained;

[0039] (2) In parts by weight, take 40 par...

Embodiment 2

[0044] Multi-walled carbon nanotubes were purchased from Beijing Deke Daojin Technology Co., Ltd.

[0045] Chitosan solution is to mix chitosan and acetic acid solution according to the mass ratio of 1:5, and stir evenly to obtain chitosan solution.

[0046] The alcohol aqueous solution is to mix ethanol and water evenly according to the mass ratio of 1:0.8 to obtain the alcohol aqueous solution.

[0047] The surfactant is sodium lauryl sulfate.

[0048] Gases are nitrogen, carbon dioxide, oxygen.

[0049] The cleaning agent is cyclopentadiene.

[0050] A preparation method of a coal-saving agent, the preparation method comprising the steps of:

[0051] (1) Mix multi-walled carbon nanotubes and chitosan solution at a mass ratio of 1:5, and ultrasonically oscillate at a temperature of 75°C for 3 hours to obtain an oscillation solution. The agent is mixed, stirred evenly, and a mixed solution is obtained;

[0052] (2) In terms of parts by weight, take 45 parts of mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com