Environmental protection type coal produced from sludge and fatlute and manufacturing method thereof

An environment-friendly, oily sludge technology, which is applied in the direction of biofuel, petroleum industry, solid fuel, etc., can solve the problems of inability to use the heat generated by sludge, cannot be discharged at will, and is difficult to degrade, so as to achieve obvious environmental protection effects and economic benefits, and improve reliability. Combustion performance, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

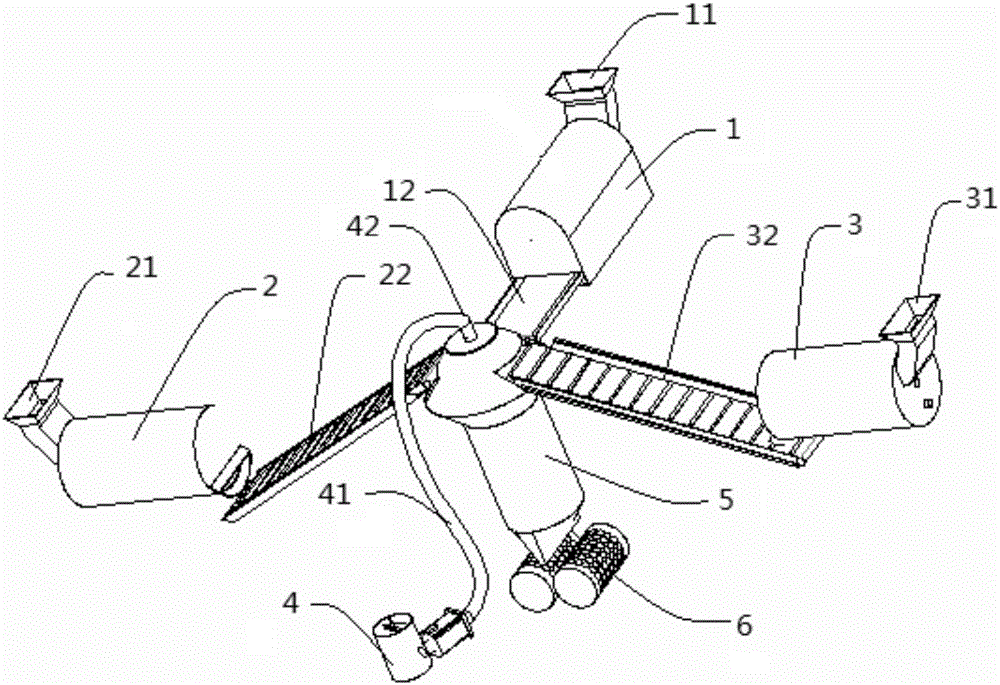

Image

Examples

Embodiment 1

[0052] Take 30 parts of press filter dewatered sludge and 0.1 part of calcium hypochlorite produced in an industrial park, add 5 parts of low-quality oil sludge from an oil refinery, 65 parts of fuel coal, 2 parts of lime, and 2 parts of binder. After mixing evenly, molding under 20MPa, the produced briquettes are free-fall test at a height of 2m without breaking.

[0053] The binder formula is: 30 parts of Inner Mongolia lignite with a humic acid content of 40%, 70 parts of papermaking black liquor, 5 parts of industrial alkali slag, and 0.3 parts of surfactant sodium lauryl polyoxyethylene ether sulfate, stirred for 2 hours Made into high viscosity briquette binder.

[0054] The viscosity-reducing treatment method of inferior oil sludge is as follows: add 20 parts of water and 0.5 part of sodium lignosulfonate to 100 parts of oil sludge, and disperse the oil sludge components by fully stirring.

Embodiment 2

[0056] Take 35 parts of press filter dewatered sludge and 0.1 part of calcium hypochlorite produced in a development zone, add 10 parts of low-quality oil sludge from an oil production plant, 60 parts of fuel coal, 2.5 parts of lime, and 3 parts of binder. After mixing evenly, molding under 20MPa, the produced briquettes are free-fall test at a height of 2m without breaking.

[0057] The binder formula is: 25 parts of lignite with a humic acid content of 40%, 75 parts of papermaking black liquor, 5 parts of industrial alkali slag, and 0.4 part of surfactant sodium lauryl polyoxyethylene ether sulfate, and stir for 2 hours Made into high viscosity briquette binder.

[0058] Among them, the viscosity-reducing treatment method of inferior oil sludge is as follows: add 15 parts of water and 0.7 parts of sodium lignosulfonate to 100 parts of oil sludge, and disperse the oil sludge components by sufficient stirring.

Embodiment 3

[0060] Take 25 parts of press filter dewatered sludge and 0.1 part of calcium hypochlorite produced in a development zone, add 5 parts of low-quality oil sludge from an oil production plant, 70 parts of fuel coal, 4 parts of lime, and 4 parts of binder. After mixing evenly, molding under 20MPa, the produced briquettes are free-fall test at a height of 2m without breaking.

[0061] The binder formula is as follows: 25 parts of lignite with a humic acid content of 35%, 70 parts of papermaking black liquor, 5 parts of industrial alkali slag, and 0.5 part of surfactant sodium lauryl polyoxyethylene ether sulfate, stirred for 2 hours Made into high viscosity briquette binder.

[0062] Among them, the viscosity-reducing treatment method of inferior oil sludge is as follows: add 20 parts of water and 0.7 parts of sodium lignosulfonate to 100 parts of oil sludge, and disperse the oil sludge components by sufficient stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com