Method for treating high-calorific-value oil sludge by using cement clinker device

A technology of cement clinker and high calorific value, which is applied in dehydration/drying/thickened sludge treatment, fuel, waste fuel, etc. It can solve the problems of high possibility of secondary pollution and high energy consumption, and achieve low processing cost and high efficiency. High effect of high utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

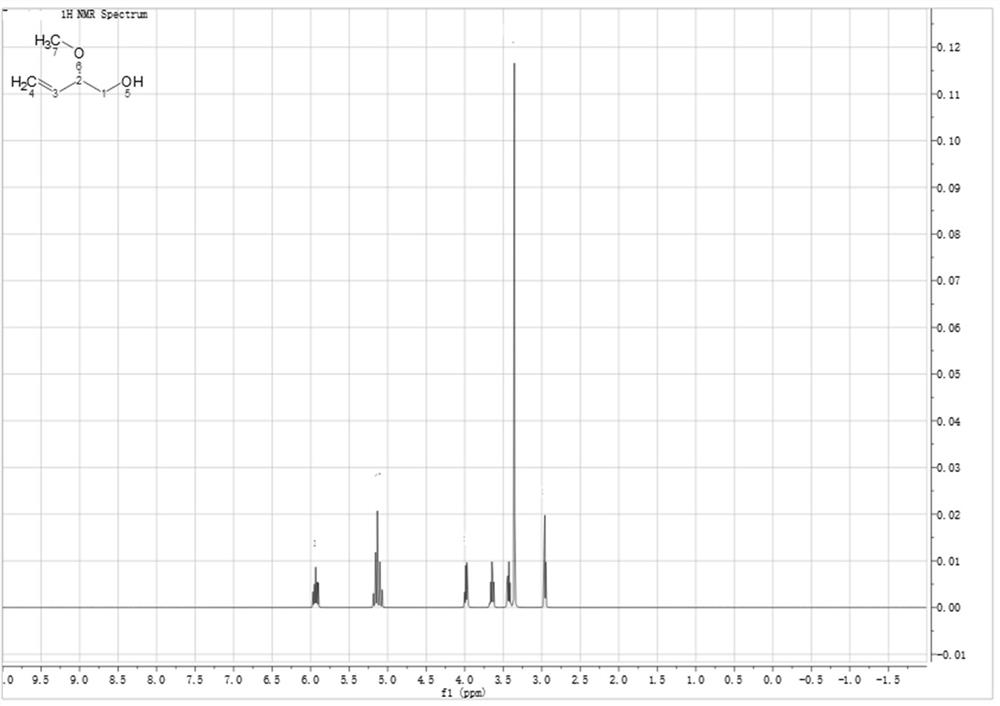

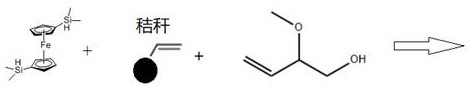

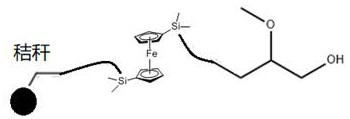

Image

Examples

Embodiment 1

[0027] A method for disposing of high calorific value sludge in a cement clinker plant, the scheme of which is as follows:

[0028] S1, dehydration treatment, adding 800kg of high calorific value oil sludge into the pressurized injection device, and quickly spraying into the drying device, the high-temperature flue gas generated by the cement kiln is passed into the drying device, and the high-temperature flue gas flows in the direction Intersect with the injection direction of high calorific value oil sludge;

[0029] S2, granulation treatment, mixing the dried high calorific value oil sludge with 1200kg coal powder evenly, and then granulating to make high calorific value oil sludge particles with uniform particle size;

[0030] S3, incineration, put the prepared high calorific value oil sludge particles into the cement kiln as fuel, and incinerate and utilize;

[0031] S4, waste residue utilization, 500kg incineration waste residue is mixed with 440kg lime, 450kg clay, 10k...

Embodiment 2

[0039] A method for disposing of high calorific value sludge in a cement clinker plant, the scheme of which is as follows:

[0040]S1, dehydration treatment, adding 900kg of high calorific value oil sludge into the pressurized injection device, and quickly spraying into the drying device, the high-temperature flue gas generated by the cement kiln is passed into the drying device, and the high-temperature flue gas flows in the direction Intersect with the injection direction of high calorific value oil sludge;

[0041] S2, granulation treatment, mixing the dried high calorific value oil sludge with 1400kg coal powder evenly, and then granulating to make high calorific value oil sludge particles with uniform particle size;

[0042] S3, incineration, put the prepared high calorific value oil sludge particles into the cement kiln as fuel, and incinerate and utilize;

[0043] S4, waste residue utilization, mix 700kg of incineration waste residue with 520kg of lime, 520kg of clay, ...

Embodiment 3

[0051] A method for disposing of high calorific value sludge in a cement clinker plant, the scheme of which is as follows:

[0052] S1, dehydration treatment, adding 1000kg of high calorific value oil sludge into the pressurized injection device, and quickly spraying into the drying device, the high-temperature flue gas generated by the cement kiln is passed into the drying device, and the high-temperature flue gas flows in the direction of Intersect with the injection direction of high calorific value oil sludge;

[0053] S2, granulation treatment, mixing the dried high calorific value oil sludge with 1600kg coal powder evenly, and then granulating to make high calorific value oil sludge particles with uniform particle size;

[0054] S3, incineration, put the prepared high calorific value oil sludge particles into the cement kiln as fuel, and incinerate and utilize;

[0055] S4, waste residue utilization, mix 800kg of incineration waste residue with 620kg of lime, 580kg of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com