Preparation method for combustible biomass coal briquette binder

A technology of binder and biomass, which is applied in the field of preparation of combustible biomass briquette binder, can solve the problems of poor waterproof performance, no combustion-supporting effect, and affecting the combustion efficiency of briquettes, and achieves a strong oxidizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

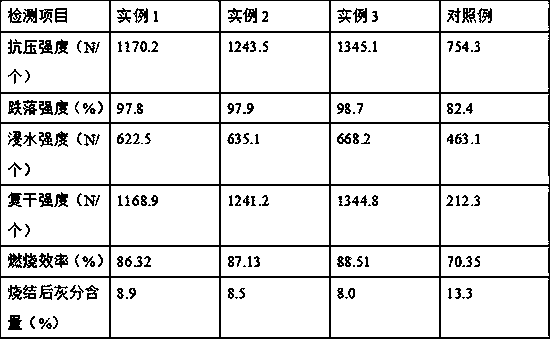

example 1

[0022] Weigh the eucalyptus wood chips and put them into the jet mill, and pulverize for 1 hour to obtain the eucalyptus wood chips. The eucalyptus wood chips and the sodium hydroxide solution with a mass fraction of 5% are mixed at a mass ratio of 1:10 and put into a beaker, and then the beaker is placed. Put it in an oil bath, heat up to 90°C, heat treatment for 2 hours, filter and separate to obtain a filter residue; mix the filter residue and a citric acid solution with a mass fraction of 30% in a mass ratio of 1:5 to obtain a mixed solution, and then transfer the mixed solution into In the autoclave, heat up to 200°C under the condition of a pressure of 2.0 MPa, and cook at high temperature and pressure for 10 hours; after the reaction is over, the pressure is naturally released, and then hydrogen is introduced into the autoclave until the pressure in the autoclave is reached. Reached 4.0MPa, stirred and reacted at 150 ° C for 1 h. After the reaction was completed, the pre...

example 2

[0024] Weigh the eucalyptus wood chips and put them into the jet mill, and pulverize for 1 hour to obtain the eucalyptus wood chips. The eucalyptus wood chips and the sodium hydroxide solution with a mass fraction of 5% are mixed at a mass ratio of 1:10 and put into a beaker, and then the beaker is placed. Put it in an oil bath, heat up to 93 °C, heat treatment for 3 hours, filter and separate to obtain a filter residue; mix the filter residue and a citric acid solution with a mass fraction of 30% in a mass ratio of 1:5 to obtain a mixed solution, and then transfer the mixed solution into In the autoclave, heat up to 230°C under the condition of a pressure of 2.3MPa, and cook at high temperature and high pressure for 11 hours; after the reaction is over, the pressure is released naturally, and then hydrogen is introduced into the autoclave until the pressure in the autoclave is reached. Reach 4.3MPa, stir and react at 180 ° C for 2 hours, after the reaction is completed, releas...

example 3

[0026] Weigh the eucalyptus wood chips and put them into the jet mill, pulverize for 2 hours, to obtain the eucalyptus wood chips, mix the eucalyptus wood chips and the sodium hydroxide solution with a mass fraction of 5% in a mass ratio of 1:10 and put them into a beaker, and then put the beaker in. Put it in an oil bath, heat up to 95°C, heat treatment for 3 hours, filter and separate to obtain a filter residue; mix the filter residue and a citric acid solution with a mass fraction of 30% in a mass ratio of 1:5 to obtain a mixture, and then transfer the mixture into In the autoclave, heat up to 250°C under the condition of a pressure of 2.5MPa, and cook at high temperature and high pressure for 12 hours; after the reaction is over, the pressure is naturally released, and then hydrogen is introduced into the autoclave until the pressure in the autoclave is reached. Reach 4.5MPa, stir and react at 200 ° C for 2 h, after the reaction is completed, release the pressure to normal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com