Petrochemical additive and preparation method thereof

A petrochemical and auxiliary technology, applied in the field of petrochemical auxiliary product manufacturing, can solve problems such as large waste of natural resources, insufficient diesel combustion, environmental pollution, etc., and achieve strong power, simple equipment and high social economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of petrochemical auxiliary agent for emulsified diesel oil, it is made up of following raw material according to weight part (Kg) proportioning:

[0028] Refinery By-Product Naphthenic Acids 78

[0029] NN Dimethylisobutylamine 8

[0030] Cyclohexylamine 6.

[0031] The preparation method is prepared by the following steps:

[0032] (a) the production method of emulsifying aid is: be about to the by-product naphthenic acid of raw material refinery, NN dimethyl isobutylamine and cyclohexylamine are fully stirred and mixed emulsification 60 minutes in the solvent of packing into under normal temperature and pressure condition, Produced as an emulsifying aid, the emulsifying aid should be stored in a stainless steel container.

[0033] (b) The production method of emulsified diesel oil: 70% of diesel oil, 15% of water and 15% of additives are fully mixed in a solvent reactor with a solvent capacity of 30 tons, and the air pressure is 1.8 through an air compressor...

Embodiment 2

[0035] A kind of petrochemical auxiliary agent for emulsified diesel oil, it is made up of following raw material according to weight part (Kg) proportioning:

[0036] Refinery by-product naphthenic acid 80

[0037] NN Dimethylisobutylamine 15

[0038] Cyclohexylamine 5.

[0039] The preparation method is the same as in Example 1.

[0040] The product name of the present invention is " new energy diesel oil ", and model is HB-f.

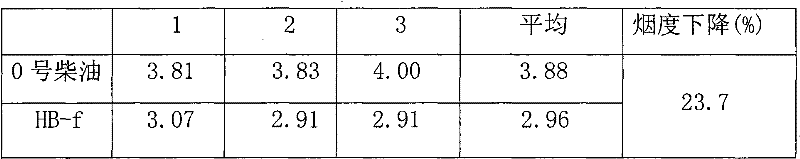

[0041] Inspection Report:

[0042] "HB-f Xinneng Diesel" engine bench inspection report.

[0043] 1. Test conditions:

[0044] 1. Test location: Xi'an Automobile Product Quality Supervision and Inspection Station;

[0045] 2. Test time: May 12-14, 2008;

[0046] 3. Environmental conditions: atmospheric pressure 96.8kPa; dry bulb temperature 34.0°C; wet bulb temperature 20.0°C.

[0047] 4. Fuel:

[0048] No. 0 diesel oil, density: 0.842;

[0049] HB-f new energy diesel, density: 0.856;

[0050] 5. Test equipment:

[0051] name

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com