Sintering mixture and mixing method, sintering ore and sintering method

A technology for sintering mixture and sintering method, applied in the field of iron ore sintering, can solve the problems of affecting the quality of sintered ore, unsatisfactory sintering mixture, complicated mixing steps, etc., so as to improve particle size and particle structure, output and yield. The effect of improving and improving the air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

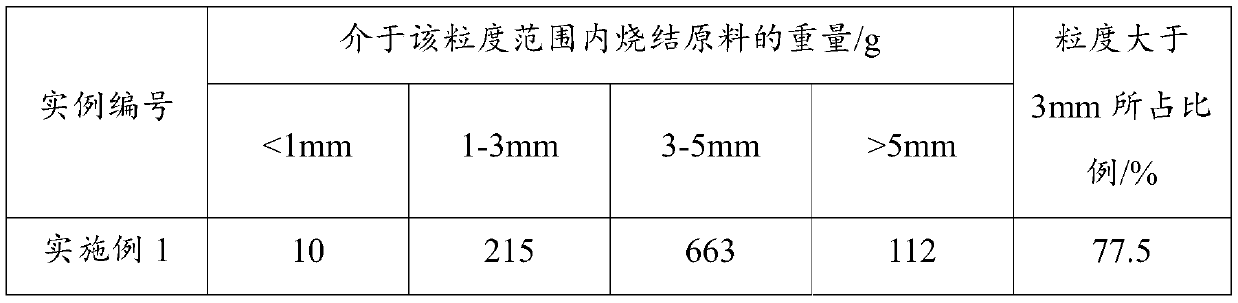

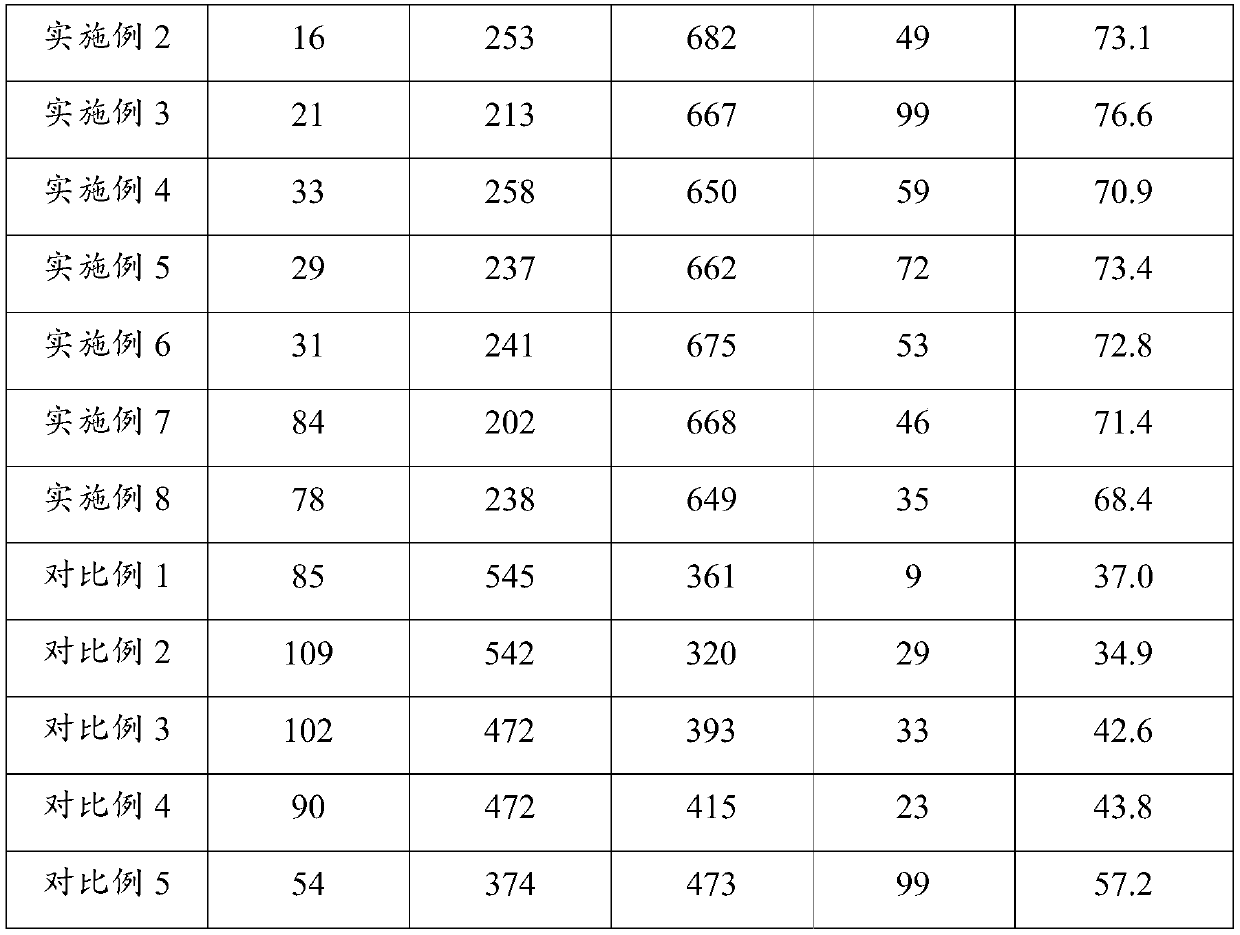

Embodiment 1

[0066] The present embodiment provides a kind of sintering method of sintering mixture, concrete steps are as follows:

[0067] (1) Add 100kg of iron ore powder to be sintered (80% of which has a particle size of less than or equal to 1mm, and 20% of which has a particle size of 1-3mm), and 18kg of 1-2mm returned ore A into the mixture machine for dry mixing for 4 minutes;

[0068] (2) Add 2.5kg of coke powder with a particle size of less than 1mm and 8.0kg of quicklime with a particle size of less than 1mm to the dry material obtained in step 1, and continue dry mixing for 3 minutes to obtain a mixed material;

[0069] (3) add 5% (mass fraction) polyvinyl alcohol (PVA) aqueous solution of 7.5kg, 9.5kg particle size in the one mixed material that step (2) obtains, continue to mix after returning ore second about 3mm, Get the second mixture;

[0070] (4) steam heating the second mixed material obtained in step (3), the material temperature is increased to 75° C., and the seco...

Embodiment 2

[0073] The present embodiment provides a kind of sintering method of sintering mixture, concrete steps are as follows:

[0074] (1) Add 100kg of iron ore powder to be sintered (80% of which has a particle size of less than or equal to 1mm, and 20% of which has a particle size of 1-3mm), and 20kg of 1-2mm return ore (A) The mixer carried out dry mixing for 5 minutes;

[0075] (2) Add 3.5kg of coke powder with a particle size of less than 1mm and 9kg of quicklime with a particle size of less than 1mm in the dry material obtained in step (1), and continue to dry mix for 3 minutes to obtain a mixed material;

[0076] (3) add the 5% (mass fraction) polyvinyl alcohol (PVA) aqueous solution of 8kg, 10kg particle size in the mixed batch that step (2) obtains, continue to mix after 4.5 minutes after returning ore B of about 3mm, obtain Second mix;

[0077] (4) steam heating the second mixed material obtained in step (3), the temperature of the material is increased to 74 ° C, and the...

Embodiment 3

[0080] The present embodiment provides a kind of sintering method of sintering mixture, concrete steps are as follows:

[0081] (1) Add 100kg of iron ore powder to be sintered (80% of which has a particle size of less than or equal to 1mm, and 20% of which has a particle size of 1-3mm), and 14kg of 1-2mm returned ore A into the mixture machine for dry mixing for 3 minutes;

[0082] (2) Add 2.5kg of coke powder with a particle size less than 1mm and 7.5kg of quicklime with a particle size less than 1mm in the dry material obtained in step (1), and continue to dry mix for 3 minutes to obtain a mixed material;

[0083] (3) add 5% (mass fraction) polyvinyl alcohol (PVA) aqueous solution, 9kg particle size to the one mixed material that step (2) obtains, continue to mix after 4.5 minutes after returning ore second about 3mm, obtain two mix;

[0084] (4) steam heating the second mixed material obtained in step (3), the material temperature is increased to 75°C, and the second mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com