Method for reducing fine particles of coal burning boiler

A fine particle, coal-fired boiler technology, applied in the direction of combustion methods, combustion equipment, fuel supply, etc., can solve the problems of equipment transformation and high operating costs, and the impact of boiler safe and stable operation, so as to reduce the amount of production and promote the semi-coke industry Effects of development and fuel cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

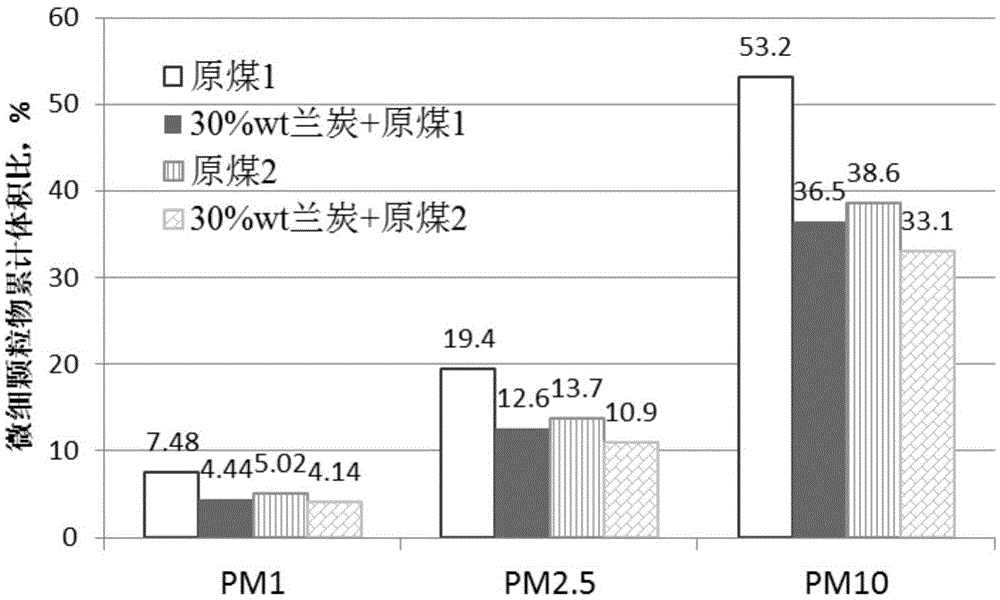

[0034] This embodiment is carried out on a 135MW bituminous coal boiler unit equipped with a medium-speed coal mill, and the specific implementation steps are as follows:

[0035] 1) According to GB / T 219-2008 "Measurement Method for Fusibility of Coal Ash" and GB / T 465-2007 "Test Method for Scouring and Wear Index of Coal", respectively, measure semi-coke and two kinds of raw coal (raw coal 1 and raw coal 2) Ash softening temperature ST (1160°C, 1300°C and 1310°C respectively) and scour wear index Ke (27.7, 1.1 and 1.0 respectively), determine that the blending ratio of blue carbon is 30%;

[0036] 2) Blending 30wt% semi-coke and raw coal 1 and 30wt% semi-coke and raw coal 2 in the coal yard evenly;

[0037] 3) In the four combustion stages, raw coal 1, 30wt% semi-coke and raw coal 1, raw coal 2, and 30wt% semi-coke and raw coal 2 are sent to the medium-speed coal mill, and the qualified fuel powder is ground once The wind is sent into the furnace;

[0038] 4) Collect flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com