A wide-thick specification pipeline steel with excellent low-temperature toughness and its manufacturing method

A low-temperature toughness, pipeline steel technology, applied in the manufacture of converters, etc., can solve problems such as manganese sulfide inclusions, pipeline damage, pipeline failure, etc., to reduce the sulfur content of steel, reduce slagging time, and improve the performance of low-temperature toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

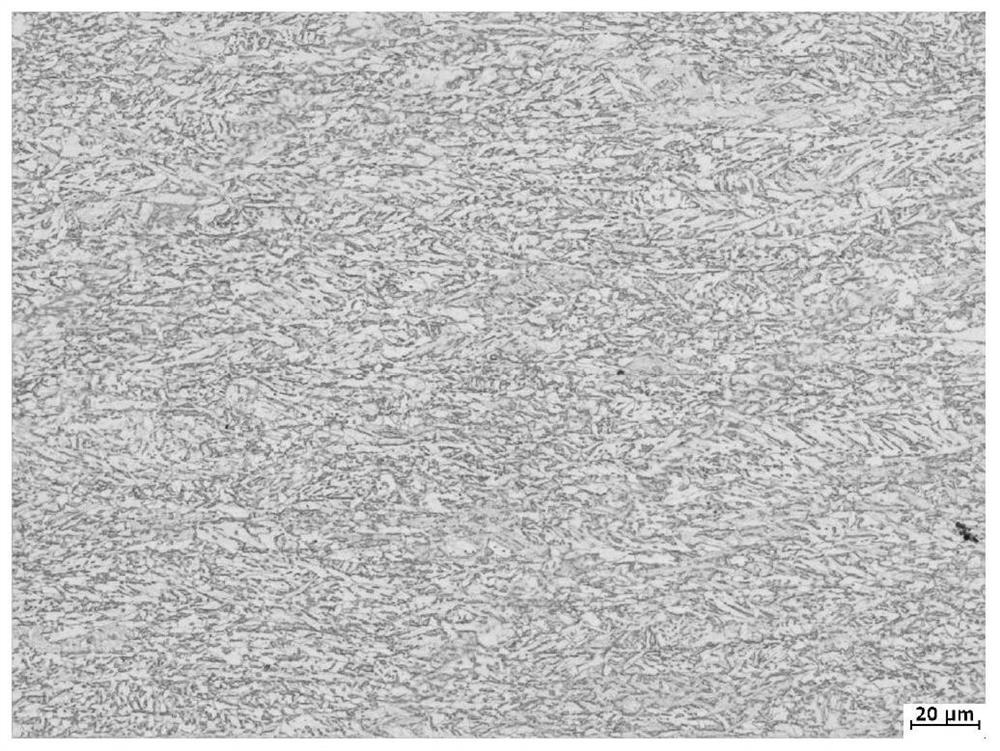

Image

Examples

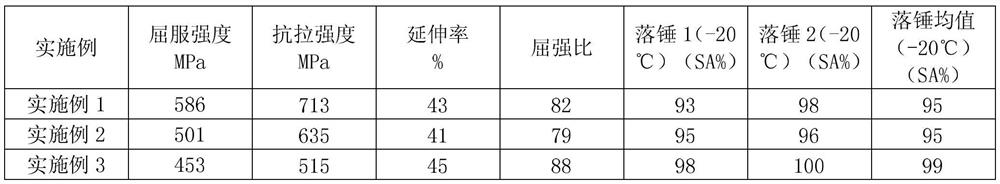

Embodiment 1

[0028] This embodiment provides a wide-thick specification pipeline steel with excellent low-temperature toughness. : 0.18%, Cr: 0.26%, Cu: 0.13%, Al: 0.011%, Nb: 0.053%, Mo: 0.13%, Ti: 0.015%, Mg: 0.0011%, N: 0.0033%, the balance is Fe and not Avoid impurities.

[0029] The manufacturing method includes the following steps:

[0030] S1. The molten iron is desulfurized by KR method, and then sent to the converter for blowing after slag removal;

[0031] S2. The top-bottom re-blowing method is adopted for blowing. Nickel, copper and molybdenum alloys are added to the converter together with the scrap steel. The converter taps are deoxidized in a strong deoxidation mode. The aluminum content after the furnace is 0.042% and the sulfur content is 0.009%;

[0032] S3. After the molten steel reaches the LF furnace, adjust the ladle bottom to blow argon, the argon flow rate is 330NL / min, power on and heat up, use lime and aluminum wire to slag, and then sample and analyze the slag ...

Embodiment 2

[0039]A wide-thick specification pipeline steel with excellent low-temperature toughness provided in this example is different from Example 1 in that its chemical composition and mass percentage are as follows: C: 0.051%, Si: 0.22%, Mn: 1.68%, P: 0.011 %, S: 0.0020%, Ni: 0.16%, Cr: 0.23%, Cu: 0.015%, Al: 0.009%, Nb: 0.039%, Mo: 0.005%, Ti: 0.017%, Mg: 0.0009%, N: 0.0036 %, the balance is Fe and inevitable impurities.

Embodiment 3

[0041] A wide-thickness specification pipeline steel with excellent low-temperature toughness provided in this example is different from Example 1 in that its chemical composition and mass percentage are as follows: C: 0.057%, Si: 0.19%, Mn: 1.59%, P: 0.013 %, S: 0.0010%, Ni: 0.03%, Cr: 0.03%, Cu: 0.02%, Al: 0.011%, Nb: 0.033%, Mo: 0.004%, Ti: 0.016%, Mg: 0.0013%, N: 0.0031 %, the balance is Fe and inevitable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com