A kind of preparation method of small particle size mechanism blue charcoal barbecue carbon

A small particle size, barbecue carbon technology, applied in solid fuel, waste fuel, petroleum industry, etc., can solve problems such as unfavorable barbecue food health and safety, difficulty in forming machine-made blue carbon, excessive dust and harmful gas emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of small particle size machine-made blue charcoal grilling carbon, the scheme is as follows:

[0032] Step 1, pulverizing, put the mechanical blue charcoal with small particle size into the crusher, and obtain the raw material blue charcoal with small particle size after pulverization, and the mass ratio of medium particle size and large particle size is 1:0.5:0.4;

[0033] Step 2, mixing, adding 80kg raw material blue charcoal obtained by pulverization into the mixer, then adding 5kg cellulose salt, mixing and stirring for 10min, adding 1.5kg binder, 0.8kg combustion-supporting agent and 3.5kg sulfur-fixing agent, and continuing Stir and mix for 10min to obtain the mixture; the described sulfur-fixing agent is a kind of catalytic composite sulfur-fixing agent, prepared according to the following method:

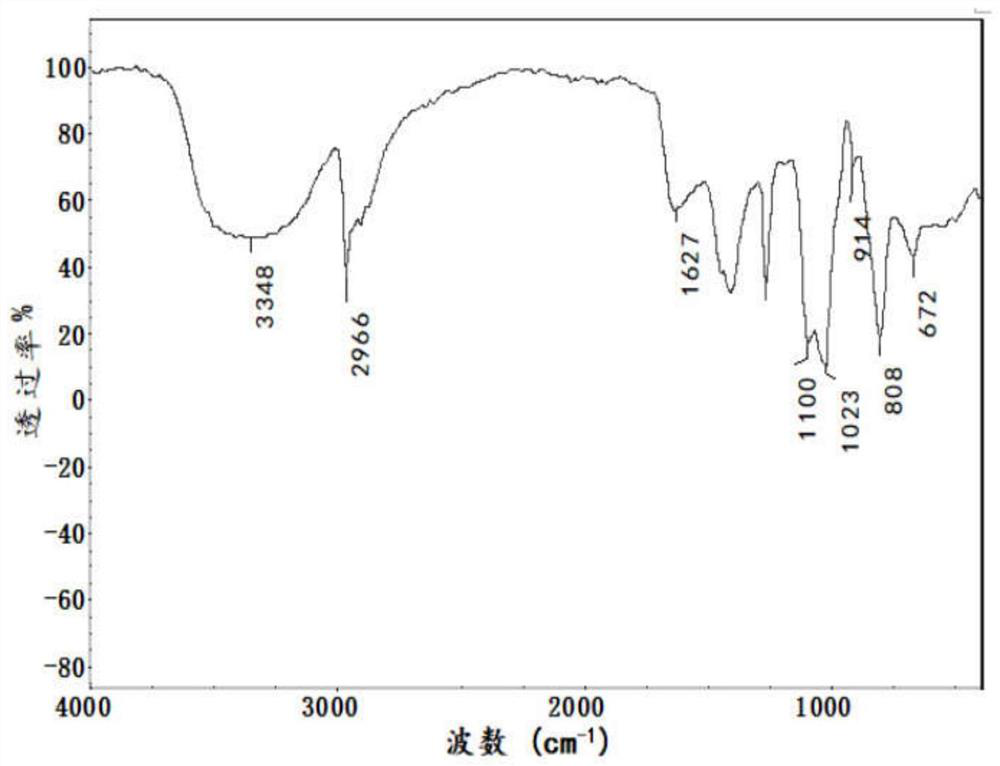

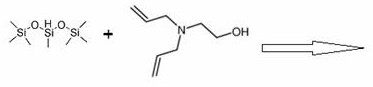

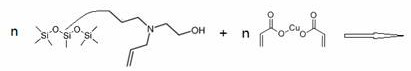

[0034] The polymethyl hydrogen siloxane of 15kg, the isopropanol solution of the chloroplatinic acid that the mass percentage concentration of 0....

Embodiment 2

[0044] A preparation method of small particle size machine-made blue charcoal grilling carbon, the scheme is as follows:

[0045] Step 1, pulverizing, put the mechanical blue charcoal with small particle size into the crusher, and obtain the raw material blue charcoal with small particle size after pulverization, and the mass ratio of medium particle size and large particle size is 1:0.8:2.4;

[0046] Step 2, mixing, adding 90kg raw material blue charcoal obtained by pulverization into the mixer, then adding 8kg cellulose salt, mixing and stirring for 20min, adding 3.5kg binder, 1.6kg combustion aid and 5.2kg sulfur-fixing agent, and continuing Stir and mix for 20min to obtain the mixture; the described sulfur-fixing agent is a kind of catalytic composite sulfur-fixing agent, prepared according to the following method:

[0047] The polymethyl hydrogen siloxane of 23kg, the isopropanol solution of 5% chloroplatinic acid with the mass percent concentration of 1.2kg, the N,N-dially...

Embodiment 3

[0057] A preparation method of small particle size machine-made blue charcoal grilling carbon, the scheme is as follows:

[0058] Step 1, pulverizing, put the machine-made blue charcoal with small particle size into the crusher, and obtain the raw material blue charcoal with small particle size after pulverization, and the mass ratio of medium particle size and large particle size is 1:1.2:4;

[0059] Step 2, mixing, adding the 100kg raw material blue charcoal obtained by pulverizing into the mixer, then adding 9kg cellulose salt, mixing and stirring for 30min, adding 4.5kg binder, 2.6kg combustion accelerant and 7.2kg sulfur-fixing agent, and continuing Stir and mix for 30min to obtain the mixture; the described sulfur-fixing agent is a kind of catalytic composite sulfur-fixing agent, prepared according to the following method:

[0060] With the polymethyl hydrogen siloxane of 30kg, the isopropanol solution of chloroplatinic acid that the mass percent concentration of 1.8kg i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com