Glass fiber composite tube

A composite material pipe and glass fiber technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of difficult management, high operating cost, and low efficiency, and achieve low smoke aerosol generation and dust removal The effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

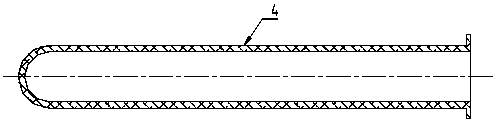

[0028] A glass fiber composite material pipe described in this embodiment is formed by mixing glass fiber material, catalyst and binder and then pressing and drying; wherein the catalyst accounts for 20% of the total mass of all materials.

[0029] The glass fiber material is glass fiber spun yarn; the catalyst is a denitration catalyst; the binder is a high temperature resistant inorganic binder.

[0030] The shape of the cross-section of the glass fiber composite pipe is circular. The size of the glass fiber composite pipe is: the diameter of the circular pipe is 250mm, the thickness of the pipe wall is 25mm, and the length of the pipe is 2500mm.

[0031] The glass fiber composite material pipe is a tubular structure with one end closed.

Embodiment 2

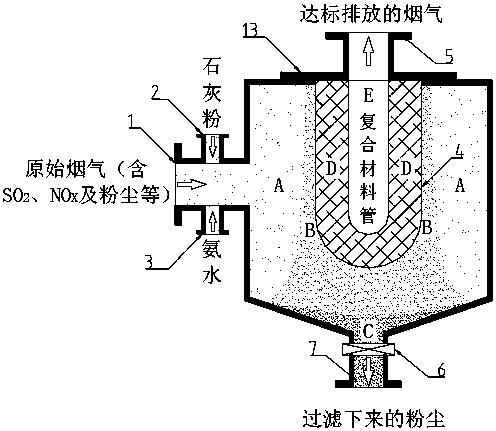

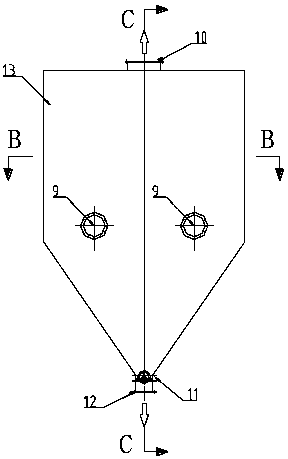

[0033] Such as image 3 , Figure 4 , Figure 5 As shown, the glass fiber composite pipe described in this embodiment has a length of 3000 mm, a diameter of 300 mm, and a wall thickness of 30 mm. it is installed in Figure 4 Among the desulfurization, denitrification and dust removal integrated devices 13, there are 5 rows, 6 in each row, 30 in total. Divided into two flue gas inlets 9, the flue gas containing sprayed lime powder and ammonia water enters the integrated device 13 from the two inlets 9, and after desulfurization, denitrification and dust removal processes, the dust is discharged from the outlet 12 through the valve 11, desulfurization and denitrification After dust removal, the flue gas that meets the emission standard is discharged from outlet 10.

[0034] Its specific working principle is as follows figure 2 As shown, the glass fiber composite pipe according to the present invention is installed inside the desulfurization, denitrification and dust remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com